Introduction

Table of Contents

ToggleAbout CES2026

CES2026 is far more than just a trade show – it is the only global event that showcases the entire technology sector in one place. This event, founded and operated by the Consumer Technology Association (CTA)®, brings together innovative ideas, breakthrough technologies, and passionate innovators from around the world.

Here, manufacturers, developers, and business leaders come together to address pressing challenges, while pioneering thinkers discuss the most critical issues in the industry through carefully planned meetings. For you, this is the ultimate destination for building connections, conducting collaborations, and transforming trend-driven concepts into market-ready products.

Trend Alignment: How YG’s Precision Manufacturing Powers CES2026 Core Tracks

1. AI + Precision Components

AI is transforming various industries by unlocking new capabilities and enhancing efficiency – the precise components it requires can keep pace with rapid innovation. You need components that can perfectly adapt to smart devices and leave no room for error.

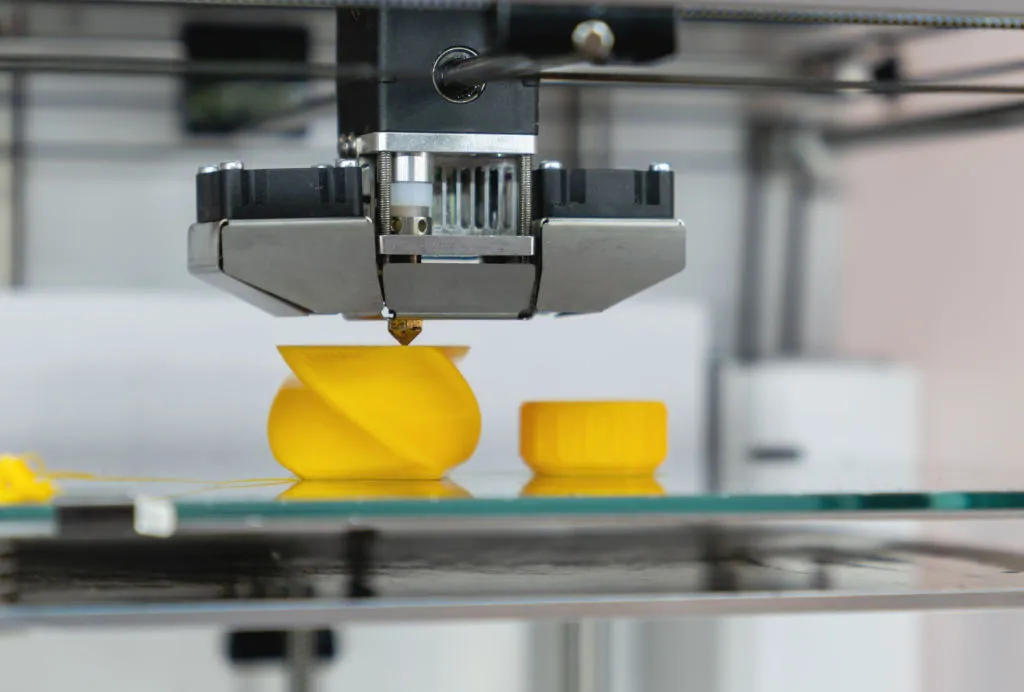

YG’s precision injection molding and rapid prototyping services can quickly bring your concepts to life. Whether it’s complex-structured components or high-performance parts, we support you in achieving rapid time-to-market and performance goals.

2. Digital Health

Digital healthcare is reshaping the way medical services are provided, and for you, this means manufacturing components that meet strict safety, compliance, and accuracy standards. The treatment outcome of the patient depends on uncompromising reliability.

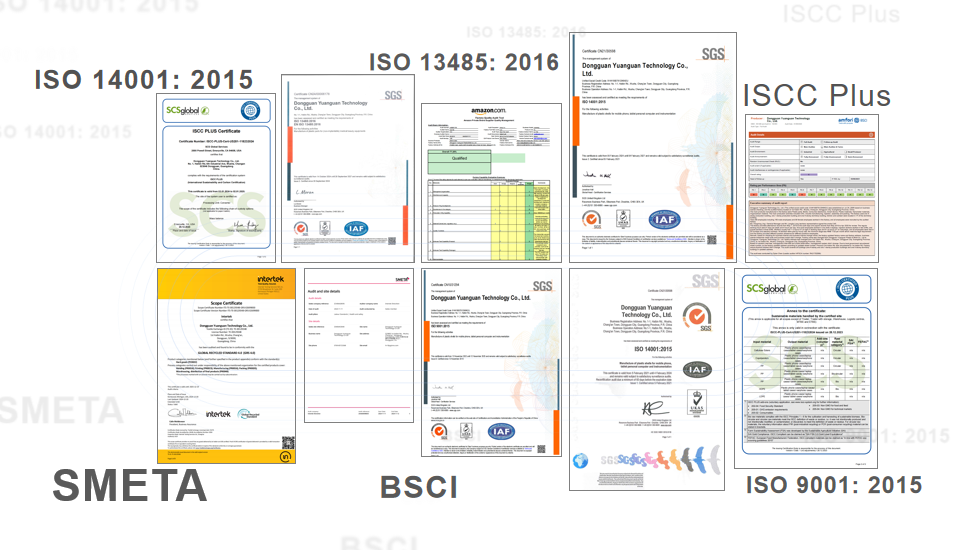

YG products have obtained multiple certifications, such as ISO, BSCl, SMETA, Reach, and GRS4.0, and are equipped with over 50 quality management personnel and conduct more than 100 third-party tests each year. We provide medical-grade injection molding components for your Internet of Things devices, telemedicine tools, and digital health solutions.

3. Smart Mobility

From self-driving cars to connected transportation systems, the requirements for components in the intelligent mobility field are that they must be able to withstand harsh environments and demonstrate long-lasting performance.

Our custom single- and multi-cavity injection molds have a service life of over 500,000 cycles and are compatible with injection molding machines ranging from 50 to 600 tons. We use over 50 types of injection molding materials (including PC/ABS/PA66+GF) to meet your needs in the automotive and mobile technology fields

4. Sustainability

Sustainability is no longer an option – it is an obligation that enterprises must fulfill. You hope to achieve green goals without sacrificing quality, efficiency, or delivery cycle.

YG combines GRS-certified eco-friendly materials with a streamlined production process to reduce waste. Our comprehensive workflow can reduce the project’s carbon footprint while ensuring its smooth progress.

5. Robotics

CES2026 highlights robotics and smart home innovations that blend convenience, safety, and eco-consciousness. These technologies require components that are both durable and precise.

YG’s mold design and injection molding technology can support the production of complex structural components used in robots and smart home devices. With over 50 compatible materials and an accuracy of ± 0.01mm, we help you create products that redefine smart living.

Why Choose YG?

1. One-Stop Turnkey Service

You don’t need to coordinate with multiple suppliers -YG’s one-stop service covers all links from ID/MD/ED design, mold making, to assembly, packaging, and 3PL delivery. The entire process is trouble-free and fully aligns with your business procedures.

No more coordination with suppliers or delays: We take care of every step to ensure your project progresses smoothly from concept to completion.

2. Innovation + Speed

Innovation is developing rapidly, and YG is no exception. With over 40 design engineers, more than 80 R&D patents, and a fast turnaround capability, we can quickly transform your ideas into prototypes – and even full-scale production – at a speed far exceeding industry standards.

We produce over 150 molds every month and more than 300,000 injection-molding parts every day, so you will never miss market opportunities.

3. Uncompromising Quality

Quality defines your brand – and it also defines YG. We have over 130 injection molding machines and more than 20 sets of professional testing equipment to ensure that every product meets your precise specification requirements.

We serve the consumer electronics, Internet of Things (IloT), medical devices, smart devices and industrial sectors – adjusting our quality standards according to the unique needs of your industry.

Meet YG at CES2026: Booth No.31801

- Discuss your specific project needs and challenges.

- Showcase sample components for AI, digital health, and mobility tech.

- Tailor one-stop solutions that align with your business goals.

Book Your Exclusive Consultation Today

Ready to turn your tech vision into reality? Secure a private 1:1 consultation with YG’s team to map out your project—from design to delivery.

Practical Resources

- International attendee guide: https://www.ces.tech/attendee-guides/step-by-step-guide-for-international-attendees/

- Latest event updates, exhibitor lists, and travel tips: https://www.ces.tech/

Conclusion

CES2026 is a stage to showcase the future of technology – and YG is your partner in precision manufacturing solutions to realize this future.

We are in line with the spirit of innovation, collaboration, and sustainable development advocated by the exhibition and are always ready to support your journey forward.

Whether you are launching new AI devices, expanding digital health products, or building the next generation of mobile technology, YG has the expertise, speed, and quality to help you turn your ideas into reality.

We can’t wait to meet you in Las Vegas, listen to your vision, and create extraordinary achievements together. Booth No.: 31801. Looking forward to meeting you!