According to new IDC market reports, the smartphone market...

Read MoreChina Phone Case Manufacturer for Global Brands

Seamless Integration of Design, Prototyping, In-House Tooling, Mass Production, and Assembly. We Handle the Complexity So You Can Focus on the Brand.

One-Stop Phone Case Manufacturer

With over 13 years of specialization, YG provides integrated manufacturing for the phone case industry. We manage the entire production lifecycle, allowing brands to streamline their supply chain through a single, accountable partner:

R&D & Engineering: Industrial design, structural engineering, and DFM.

Tooling & Production: Mold flow analysis, mold design, mold making, sourcing, and precision injection molding.

Secondary Operations: Post-processing, finishing, and final assembly.

Packaging & Logistics: Custom packaging design, packing, and integrated 3PL delivery.

- ISO 9001 / 13485 / 14001 Certified

- ±0.01mm Precision Manufacturing

- GRS 4.0 - Recycled & Eco-Materials

- Strict NDA Compliance & Design Security

Custom Cell Phone Case Manufacturer

As a leading custom phone case manufacturer, we transform your unique requirements into market-ready products. Every element is tailored to your brand. Explore popular custom styles below.

YG TeCH Phone Case Manufacturing Service

Your one-stop manufacturing solution for premium phone cases. From engineering design to final retail packaging, YG TeCH integrates every step—including prototyping, precision tooling, injection molding, and surface finishing—into a seamless and scalable process to accelerate your time-to-market.

Phone Case Manufacturing Capabilities

Our manufacturing capabilities are built on precision and scale. Equipped with advanced Sumitomo injection molding machines and high-speed CNC centers, we maintain tolerances within ±0.01mm to ensure flawless product integration. From dual-material (2K) molding to high-volume production, our facility is engineered to meet the most demanding technical standards and delivery timelines.

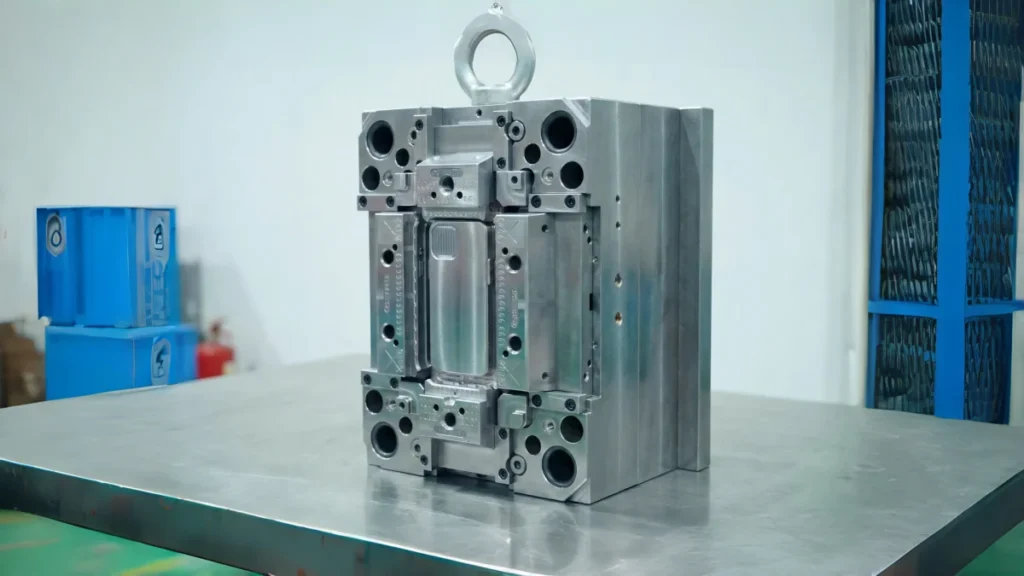

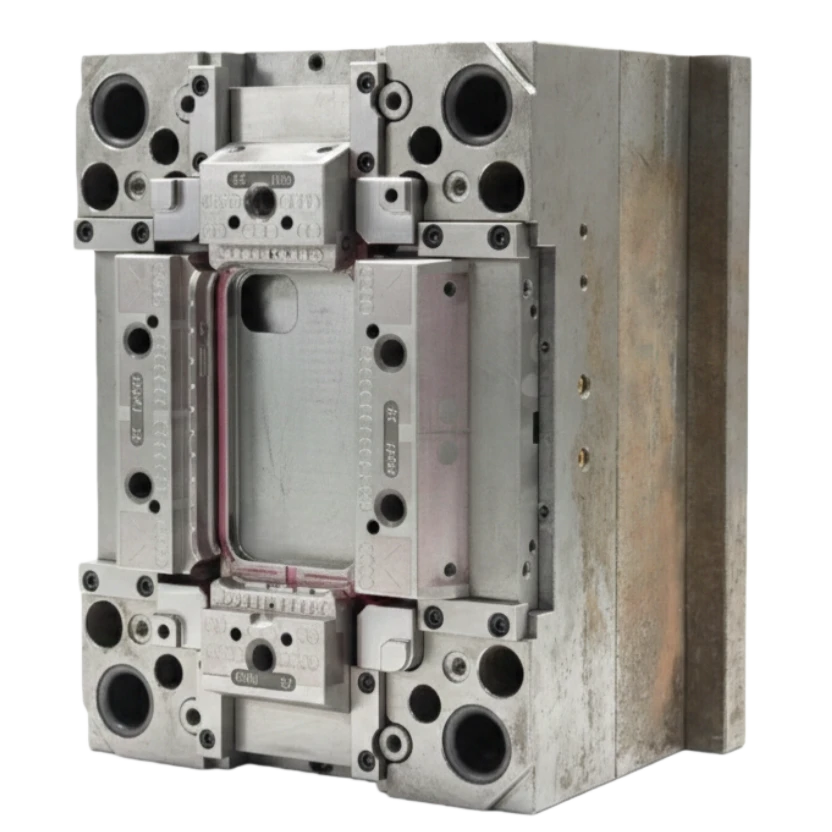

1. Precision Tooling

- Monthly Capacity: 150+ sets of high-precision molds (718H, S136, NAK80).

- Equipment: In-house CNC, EDM, and Wire-cutting machines (Makino, Mikron, FANUC).

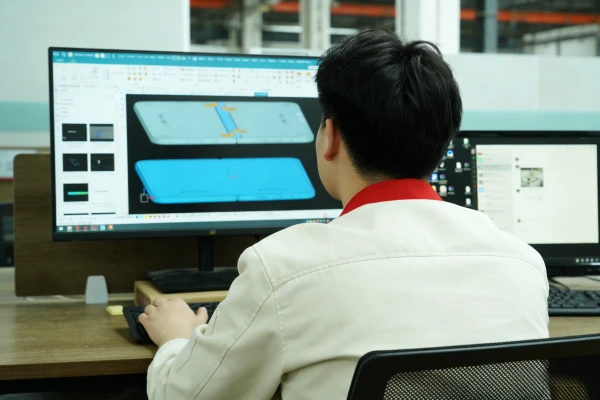

- Technical Analysis: Pre-production DFM and Moldflow simulation to optimize gate placement and minimize cycle time.

- Maintenance: Automated mold maintenance protocol ensuring consistent part quality over long production runs.

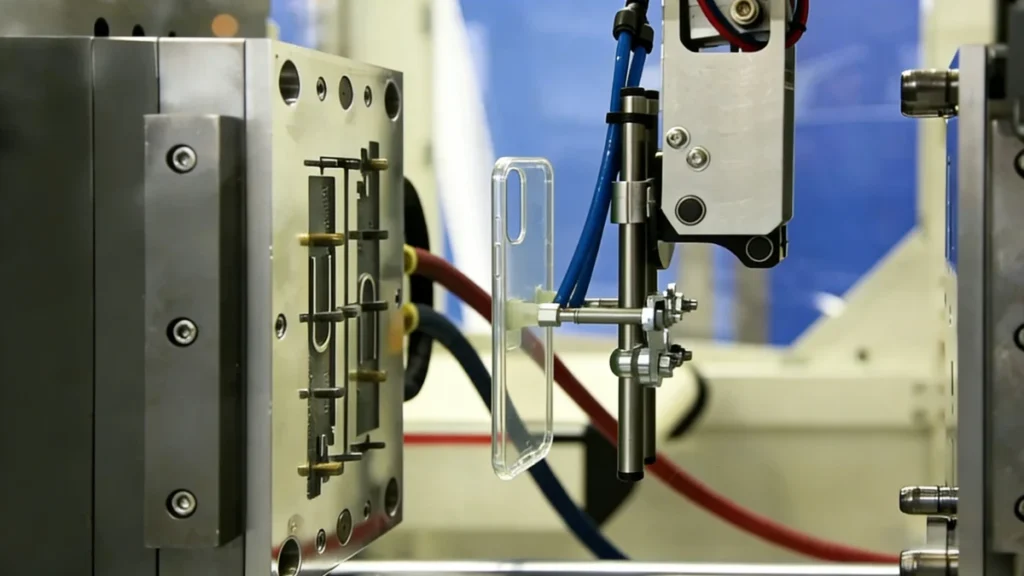

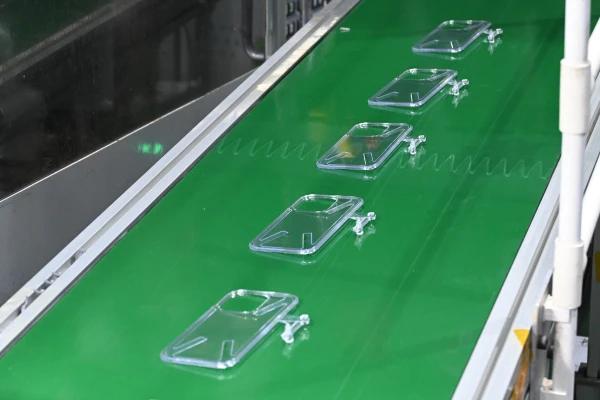

2. Advanced Injection Molding

- Machine Range: 90T to 1000T horizontal and vertical injection presses (FANUC, Niigata, Sumitomo).

- Specialized Processes: Multi-shot (2K) molding, Overmolding, and IML/IMD integration.

- Environment: Dust-free workshop for high-gloss and transparent case production.

- Automation: Robotic arm operation for improved precision and production efficiency.

3. Material Science & Versatility

- Standard Resins: Premium TPU, PC, TPE, and Liquid Silicone (LSR).

- Sustainable Solutions: GRS-certified recycled plastics and Bio-based compostable materials.

- Advanced Composites: Integration of Aramid fiber (Kevlar), Carbon fiber, and metal inserts.

- Customization: In-house color laboratory for precise Pantone/RAL matching.

4. Secondary Operations & Assembly

- Finishing: UV coating, soft-touch painting, vacuum plating (NCVM), and laser engraving.

- Assembly: Semi-automated assembly lines for multi-component cases and MagSafe magnet integration.

- Functional Testing: 100% on-line fitment testing and tactile feedback validation.

- Packaging: Custom retail-ready packaging design, printing, and automated packing.

Ready To Elevate Your Brand?

Partner with YG TeCH, your trusted phone case supplier, for innovative solutions. Contact us today to discuss how we can bring your vision to life with our customized phone case offerings.

Phone Case Customization Capabilities

We provide comprehensive OEM/ODM solutions tailored to your brand’s specific requirements. From structural engineering and material formulation to surface finishing and retail packaging, we deliver precise customization to ensure market differentiation.

1. Materials

Diverse material options including high-transparency PC, anti-yellowing TPU, liquid silicone, and GRS-certified recycled plastics.

2. Structural Design

Custom mold development for unique 3D shapes, ultra-slim profiles, or heavy-duty dual-layer structures.

3. Functional Integration

Integration of functional components such as N52 MagSafe arrays, responsive metal buttons, kickstands, and lanyard holes.

4. Surface Finishes

Tactile treatments to enhance grip and feel. Options include soft-touch rubber oil, sandy finish, glossy UV coating, and 3D textures.

5. Branding & Identity

Visual customization to highlight your brand. We offer high-precision IMD/IML, laser engraving, pad printing, and embossed logos.

6. Retail Packaging

End-to-end packaging solutions. We create custom gift boxes, eco-friendly pulp trays, and handle final kitting and labeling.

Why Partner with YG TeCH

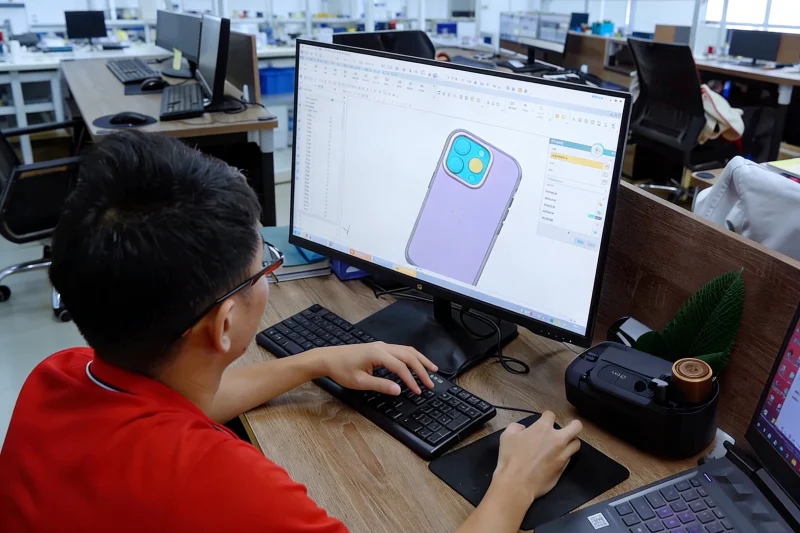

1. Engineering & Technical Analysis

- Pre-tooling DFM optimization

- Integrated Moldflow simulation

- Structural feasibility assessment

03. Material & Resin Expertise

- GRS 4.0-certified recycled polymers

- RoHS/REACH testing for all incoming raw materials

- Custom color matching (Pantone/RAL)

2. Tooling & Machining Precision

- In-house CNC & EDM machining

- ± 0.01mm tolerance control

- Multi-cavity mold design expertise

4. Quality Control & Validation

- 60+ dedicated QC specialists

- 1,000+ third-party lab tests

- Full-dimensional measurement reporting

YG TeCH Phone Case Manufacturing Process

We implement a standardized 10-stage manufacturing protocol covering everything from DFM engineering to global fulfillment. Every step is optimized for scalability and strict quality control, ensuring your product moves efficiently from concept to reality.

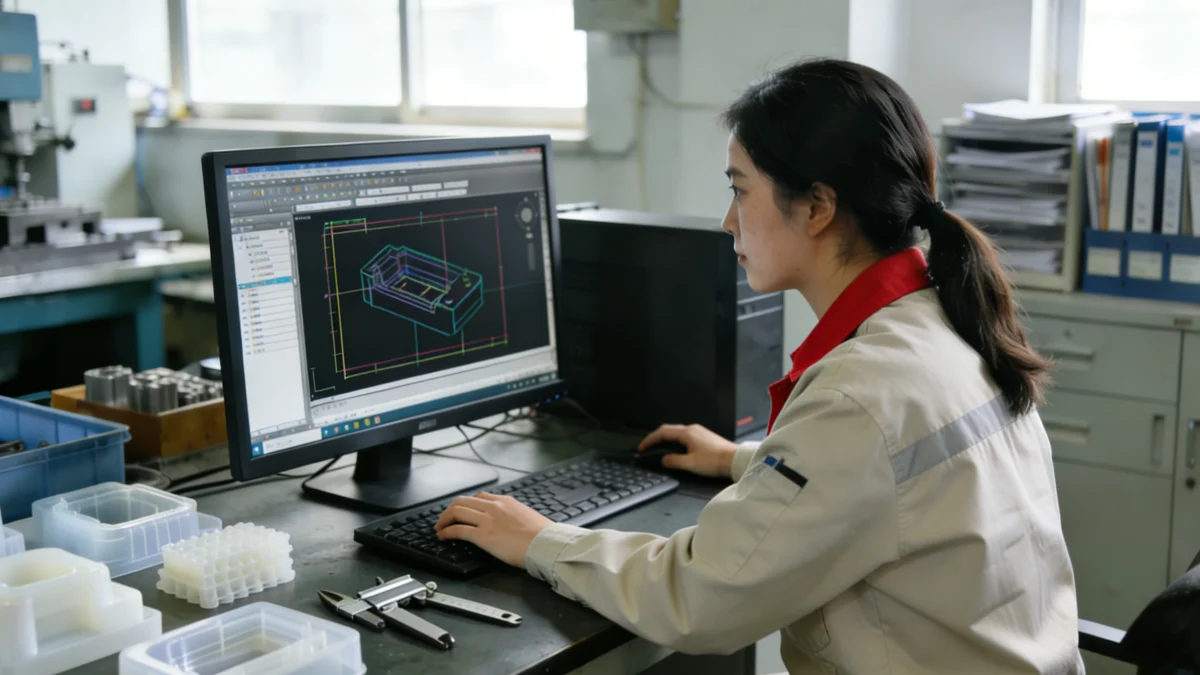

1. Design & DFM Analysis

Review 3D files for manufacturing feasibility. We analyze draft angles, wall thickness, and shrinkage rates to identify and resolve potential defects before tooling.

2. Material Selection

Select materials based on performance requirements and cost targets. We verify supply chain stability and ensure compliance with environmental standards like RoHS and REACH.

3. Rapid Prototyping

Produce physical samples using 3D printing or CNC machining. This verifies the structural fit, ergonomics, and overall dimensions prior to steel mold fabrication.

4. Precision Mold Fabrication

Machine the mold core and cavity using high-speed CNC and EDM equipment. We ensure steel hardness and processing accuracy meet the specified tolerances.

5. T1 Trial & Mold Optimization

Conduct initial trial runs (T1) to test mold performance. We identify issues such as flash or short shots and adjust mold parameters until the part meets specifications.

6. Golden Sample

Submit the optimized sample for client sign-off. This sealed sample serves as the unified quality standard and reference for all subsequent mass production.

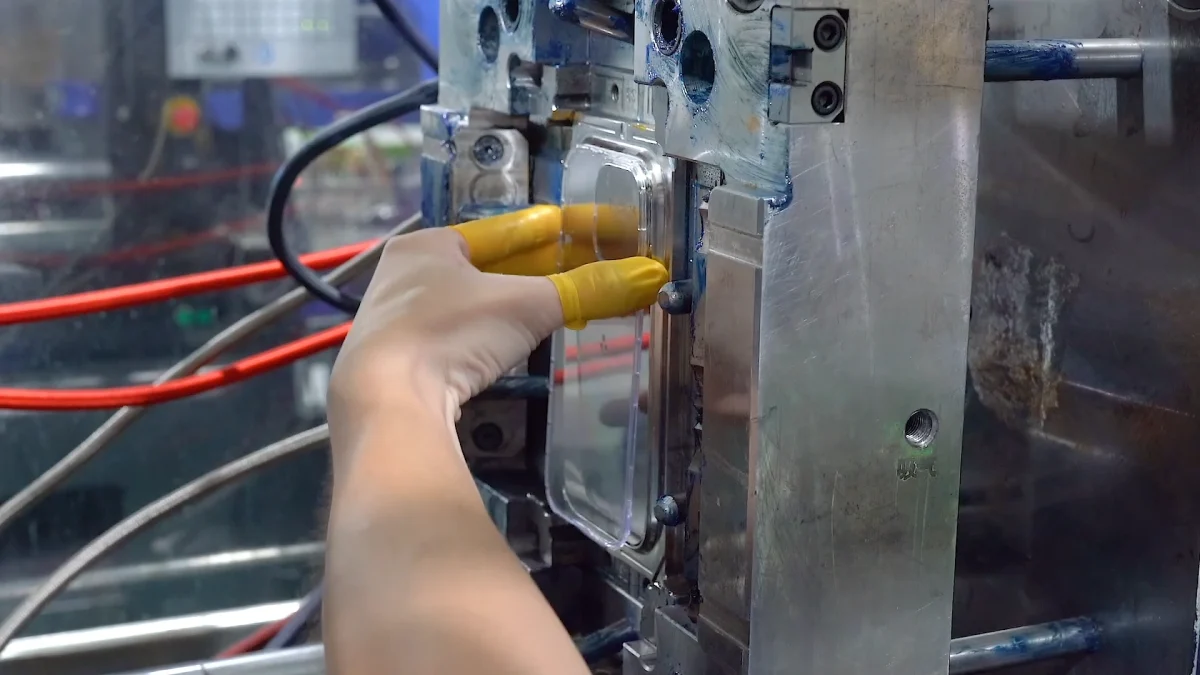

7. Mass Injection Molding

Execute volume production using automated injection machines. We monitor cycle times, injection pressure, and material flow to maintain consistency across batches.

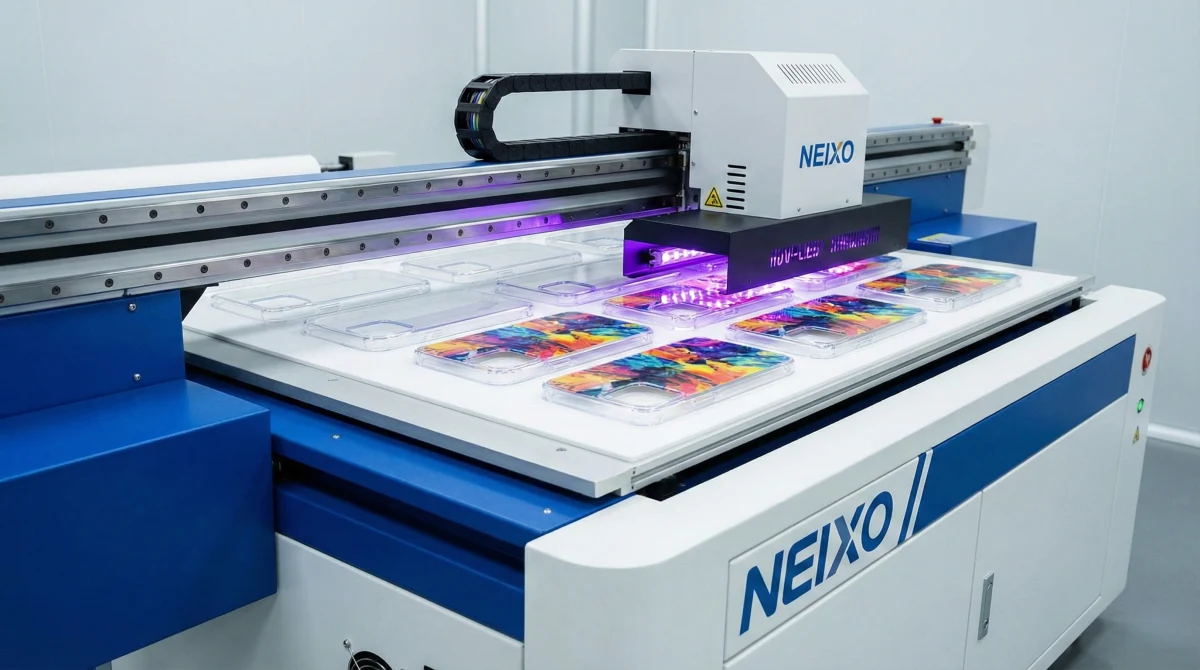

8. Surface Finishing

Apply post-molding treatments to specific requirements. This includes spray painting, UV coating, electroplating, or laser etching for texture and visual effects.

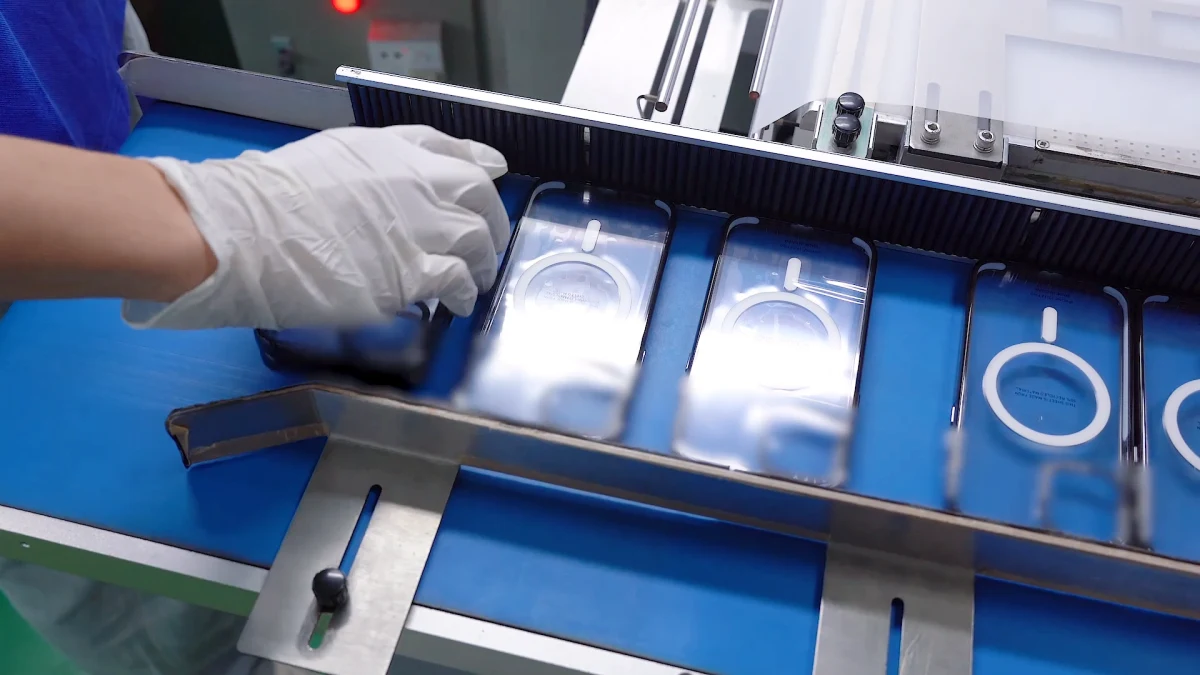

9. Secondary Assembly

Install functional components onto the case body. Operations include gluing, heat staking, or press-fitting parts like MagSafe magnets, metal buttons, and camera rings.

10. Packaging & Logistics

Complete final packaging and labeling according to retail specifications. We arrange warehousing and coordinate global shipping via air or sea freight (FOB/DDP).

Grateful for Their Trust

FAQ

What is the MOQ for custom phone case manufacturing?

Our standard MOQ starts at 1,000 pcs per model/color. However, we offer flexible support for new project trials or high-complexity designs. Contact our team to discuss your specific volume needs.

What is the typical lead time for mold making and mass production?

Timelines depend on complexity, but standard schedules are:

Prototyping: 3–5 days.

Tooling (T1 Sample): 20–30 days.

Mass Production: 15–20 days after sample approval.

Do you source specific materials like eco-friendly plastics or MagSafe magnets?

Yes. We have a verified supply chain for GRS-certified recycled materials, anti-yellowing TPU (Bayer/Sabic), and high-grade MagSafe magnets (N52). We handle all material compliance (RoHS/REACH) for you.

Do you provide DFM analysis for design optimization?

Absolutely. Before cutting steel, our engineers perform a comprehensive DFM (Design for Manufacturability) analysis. We identify risks like sink marks or warping and optimize your 3D files to ensure structural integrity and cosmetic perfection.

How do you handle IP protection and NDAs?

Protecting your design is our priority. We sign a strict Non-Disclosure Agreement (NDA) before receiving any files. Your molds and proprietary designs are kept confidential and are never shared with third parties.

Do you offer retail packaging and global logistics services?

Yes, we provide an end-to-end solution. This includes custom retail packaging, kitting (assembly with accessories), and global shipping (FOB/DDP) directly to your warehouse or Amazon FBA centers.

Latest Blog

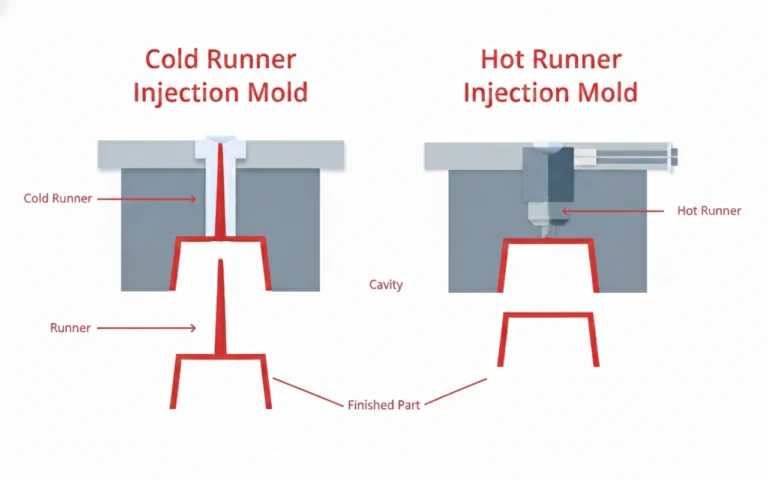

Hot Runner vs Cold Runner Injection Molding:

Deciding between hot runner vs cold runner injection...

Read MoreCold Runner Injection Molding: The Complete Guide

Selecting the right tooling system is a high-stakes...

Read More