For global phone case brands, quality, consistency, and compliance are the bottom lines that are beyond question. Defective fit, uneven textur,e or extended delivery cycles can all disrupt your supply chain and damage customers’ trust.

Precision injection molding is a manufacturing process that addresses these pain points and is the pillar of high-performance phone cases that meet strict global standards.

This guide explains what precision injection molding is, its importance to your business, and how to make informed decisions when selecting a manufacturing partner.

What Is Precision Injection Molding?

Table of Contents

TogglePrecision injection molding is a specialized technical process that injects molten plastic into precisely designed molds under high pressure to produce components with consistent, detailed, and ultra-precise tolerances – a level of accuracy far exceeding that achievable by traditional molding processes.

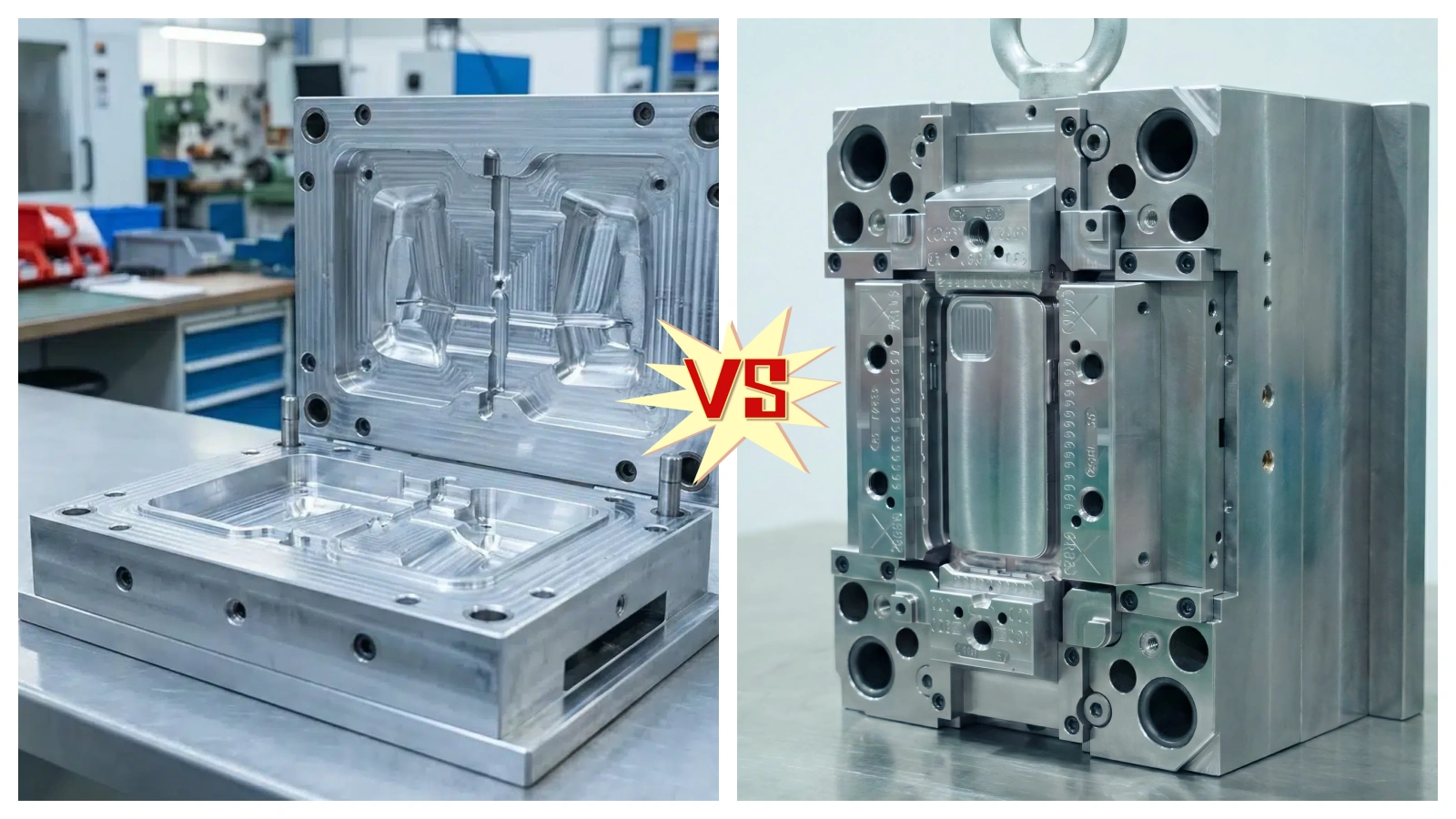

Unlike the standard injection molding process, this process places more emphasis on repeatability and accuracy. Its tolerance can reach a strict level of ± 0.005 millimeters. For phone cases, this means that each component can fit perfectly without any misalignment or warping of the cutting edge.

Consider the magnetic phone cases or the thin, high-end designs favored by customers – precision injection molding technology can ensure uniform material distribution and precise dimensions, making these innovations possible.

Why Precision Matters for Your Phone Case Line

Consumers’ demands for quality: A phone case that aligns with the buttons, protects the camera, and has a durable feel. Even minor defects can lead to returns or negative reviews.

Accuracy eliminates these risks by ensuring the consistency of thousands of components. Whether you are purchasing 5,000 or 50,000 products, precise injection molding technology can ensure that each product meets the same high standards.

For phone case manufacturers, precision is not merely a technical detail – it is a business necessity for building long-term customer loyalty.

Precision Injection Molding vs. Traditional Injection Molding

| Aspect | Precision Injection Molding | Traditional Injection Molding |

|---|---|---|

| Tolerance range | ±0.005–0.02mm (tight, consistent) | ±0.05–0.1mm (loose, variable) |

| Mass production consistency | Near-zero variation between units | Higher defect rates (flash, warping) |

| Suitability for your needs | Ideal for premium, functional designs (magnetic, waterproof, slim) | Better for low-cost, basic cases |

| Lead time efficiency | Optimized setup for scalable runs | Longer adjustments, inconsistent timelines |

For medium and high-end phone case production lines, precision injection molding is an investment that can bring returns. A reduction in defects means lower waste costs, fewer returns, and higher customer satisfaction – all of which can boost a company’s profits.

Key Benefits of Precision Injection Molding

Unparalleled quality and consistency

The phone cases you need must perform well in every batch as promised. Precision injection molding can eliminate common defects, such as misaligned camera openings, uneven thickness, or fragile edges.

These details are crucial for the global market because consumers expect to obtain high-quality products. Choosing a manufacturer that adopts precision injection molding technology can ensure that your products stand out for their reliability.

Cost-Effectiveness for Scalable Orders

Although the initial cost of precision molds is relatively high, the value of long-term savings is very significant. Precision injection molding typically achieves a defect rate of ≤0.5%, thereby reducing waste and avoiding expensive scrap disposal costs.

For large orders, this efficiency translates into lower unit costs. As your business grows, precision injection molding will expand in tandem with you – never compromising on quality or budget.

Flexibility for Innovative Designs

Your customers want unique and practical phone cases – and precision injection molding technology can help you achieve this goal. Whether you are designing slender contours, integrated magnetic rings, or textured surfaces, this process can support the realization of complex functions.

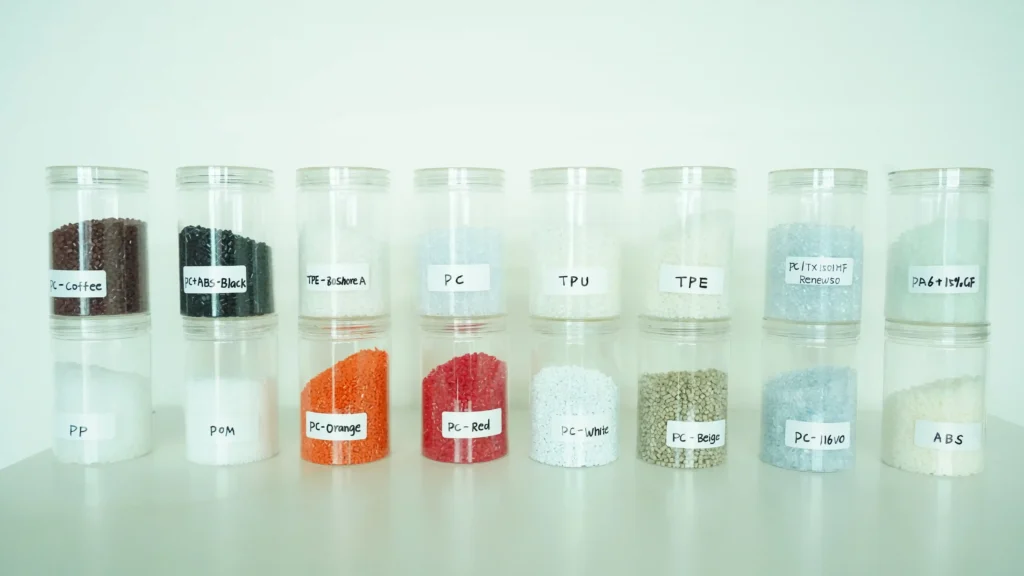

Even multi-material combinations (such as TPU+PC) can be achieved through precision injection molding. This flexibility helps you stay ahead of market trends and differentiate your product line.

Compliance with Global Standards

Selling in the global market requires compliance with stringent regulations, including ROHS, REACH, and FDA. Phone case manufacturers that use precision injection molding processes give priority to non-toxic materials that meet these general standards.

You can purchase with confidence as your products are safe for end users and comply with regional laws – there will be no delays or penalties due to non-compliance.

Precision Injection Molding Process

Understanding the precision injection molding process helps you evaluate suppliers and optimize designs. The following is the simplified decomposition provided for you. For the detailed process, you can refer to another blog post of ours

Step 1: Mold design and engineering

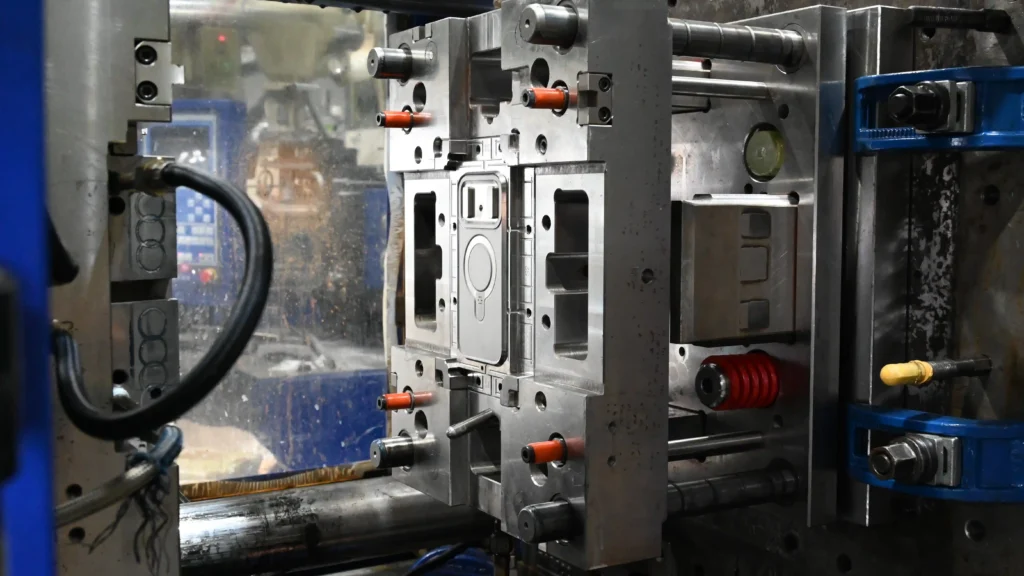

Precision begins with molds. High-quality molds are manufactured using advanced technologies, including five-axis CNC machining, electrical discharge machining (EDM), and wire cutting.

These processes operate in coordination: 5-axis CNC machining is used to shape the basic structure of the mold, electrical discharge machining is responsible for creating complex cavities and details, and wire-cut electrical discharge machining ensures ultra-precision cutting while minimizing material waste to the greatest extent.

Some cellphone case manufacturers, such as YG, will provide a DFM report for your design to optimize it before production starts.

This step ensures that your phone case is moldable, cost-effective, and free of potential defects – saving you time and money in the future.

Step 2: Material Selection

Manufacturers use high-end plastics such as TPU, PC, and recycled materials to tailor specific requirements. Whether your priority is impact resistance, UV protection, or environmental friendliness, the right material is the key to performance.

All materials should comply with global compliance standards, so you don’t have to sacrifice sustainability or safety for durability.

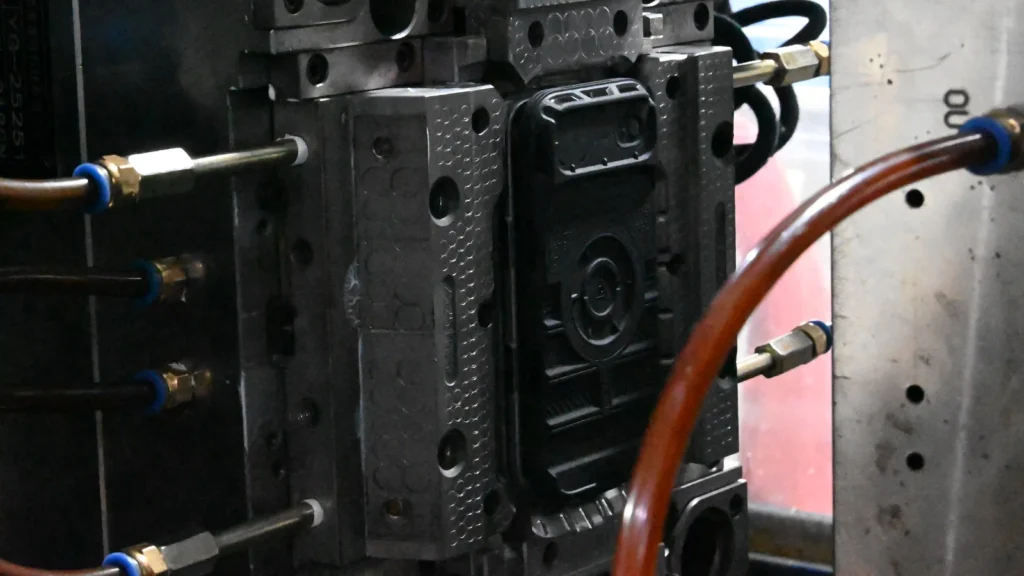

Step 3: Injection Molding

Automated injection molding machines inject molten plastic into molds under precise temperature and pressure. Real-time monitoring of these variables ensures consistency in each unit.

The most advanced equipment minimizes human errors to the greatest extent, so even for large orders, you can obtain reliable quality.

Step 4: Post-Processing & Quality Control

After injection molding, each phone case must go through deburring, surface treatment (matte, glossy, anti-slip treatment), and 100% visual inspection. At the same time, dimensional inspection will also be carried out to ensure that the tolerance meets the specification requirements.

Reputable manufacturers will maintain strict quality control processes to ensure that each product fully meets your specific requirements before shipment

What to Look for in a Phone Case Manufacturer Using Precision Injection Molding

Not all phone case manufacturers are the same in terms of precision injection molding. The following are the non-negotiable factors that must be taken into consideration

1. Proven Precision Molding Expertise

Case or sample parts with tolerance specifications are required. Reliable manufacturers should be transparent about their processes and results.

Look for evidence of advanced mold manufacturing capabilities, including 5-axis CNC, electrical discharge machining (EDM), and wire cutting – these are signs of a commitment to pursuing precision.

2. Design for Manufacturability Support

Manufacturability design is crucial for optimizing your design and avoiding production problems. Many reputable manufacturers offer this service for free to help simplify the production process.

This support ensures that your design is compatible with precision injection molding, reducing costs and enhancing the quality of the final product.

3. Quality certification

Please look for ISO9001, ROHS, and REACH certifications. These prove that the manufacturer adheres to global quality and compliance standards.

Certification is a tangible sign of a manufacturer’s commitment to consistency and safety.

4. Transparent production process

You should be able to view the status of your order. Please select a manufacturer that provides real-time tracking and defect rate reports.

Transparency helps you predict delays and make informed decisions about your supply chain.

5. Scalability

Your business is growing, and suppliers should also grow with you. Ensure that manufacturers can handle large orders (more than 10,000 pieces) without sacrificing quality.

The best manufacturers focus on scalable precision injection molding, balancing speed and accuracy to meet the demands of orders of any size.

Common Myths About Precision Injection Molding

Let’s dispel those misunderstandings that may prevent you from choosing precision injection molding:

Misconception 1: “Precision injection molding is too expensive for small-batch orders.”

Fact: Many manufacturers have a minimum order quantity requirement, with a minimum of 1,000 pieces, and offer competitive prices for orders that can be mass-produced. A lower defect rate means you can save on costs related to scrap and returns, even for smaller orders.

Misconception 2: “Traditional injection molding processes are sufficient to meet the requirements of basic phone cases.”

Fact: Even basic products need to maintain consistency. Precision injection molding can reduce rework and enhance customer loyalty. In the long run, this will save you money. Your buyers will be able to notice the difference in quality.

Misconception 3: “All phone case manufacturers use the same precision injection molding standards.”

Fact: Quality varies due to differences in mold quality, machine calibration, and quality control processes. Be sure to verify the manufacturer’s tolerance specifications, mold-making processes, and certification information – do not trust them blindly just based on their oral statements.

Conclusion

Precision injection molding is the key to creating phone cases that meet the high standards of global buyers. It offers quality, consistency, and flexibility – all of which are key to your purchasing success.

When choosing partners, give priority to those with advanced mold manufacturing capabilities (including 5-axis CNC, EDM, and wire EDM), transparent processes, and compliance commitments. These factors ensure that the products you receive are in line with your brand’s reputation for quality.

For those seeking to optimize their design, excellent phone case manufacturers like YG offer free DFM reports to simplify production and reduce costs. This type of support can effectively turn your phone case ideas into reality.