Injection molding tools are the key to large-scale production. This guide provides detailed information on all the necessary knowledge about plastic injection molds, from basic concepts to intelligent selection strategies.

After reading this guide, you will be able to gain relevant insights and select molds that meet your production goals and quality standards

What is Tooling in Injection Molding?

Table of Contents

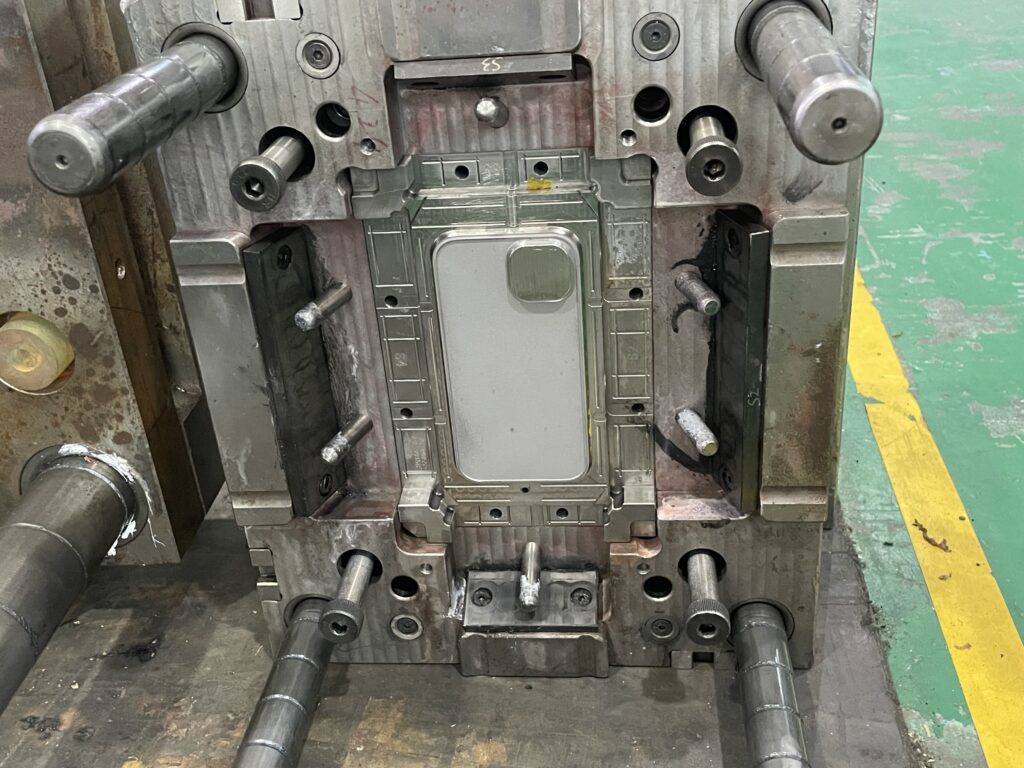

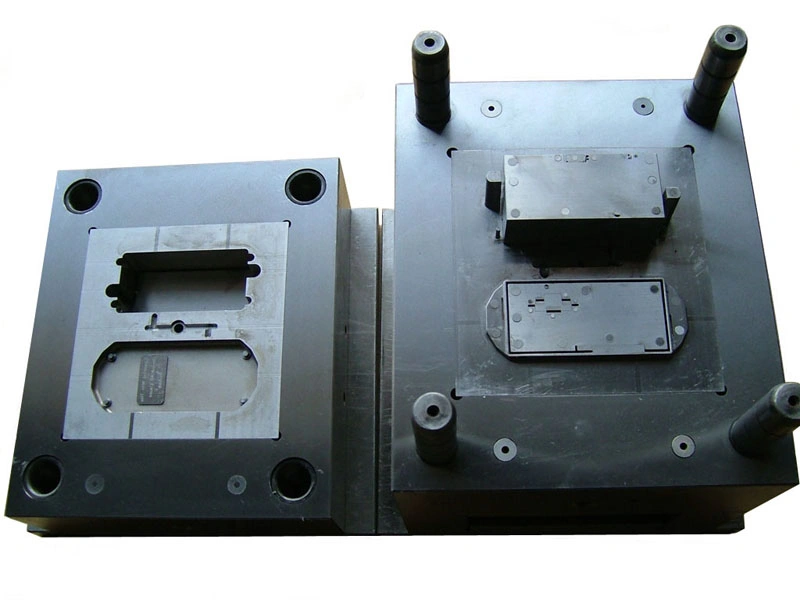

ToggleEssentially, a plastic injection mold is a customized tool that enables the mass production of finished products of consistent quality from molten plastic.

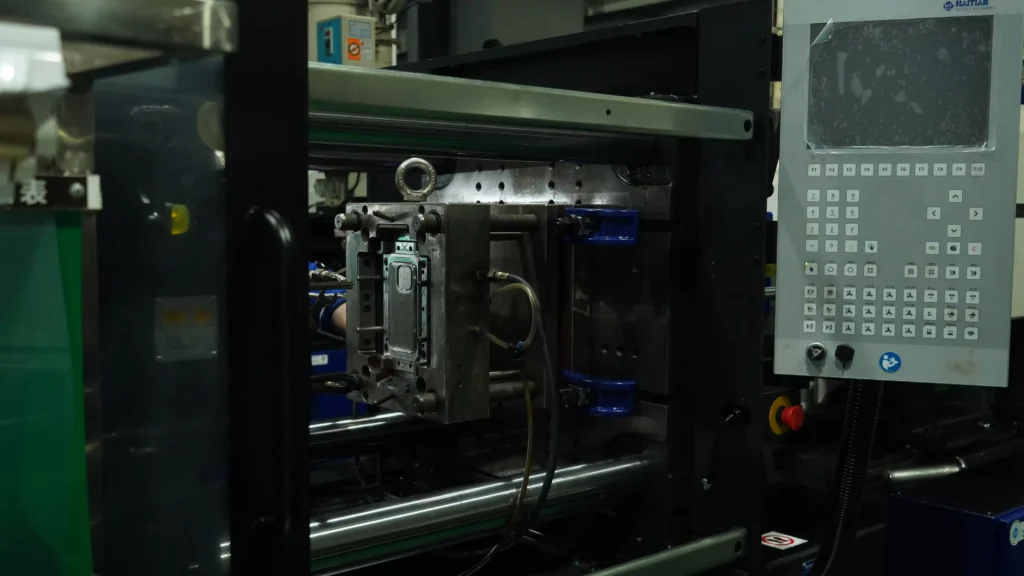

This process is quite simple: heated plastic resin is injected into the “cavity” of the mold under high pressure (matching the design of the product), then cooled and solidified. After that, the mold is opened, and the finished product is ejected.

What is its greatest advantage for you? Consistent large-scale production. By using the right mold for injection molding, you can produce hundreds of identical parts per hour.

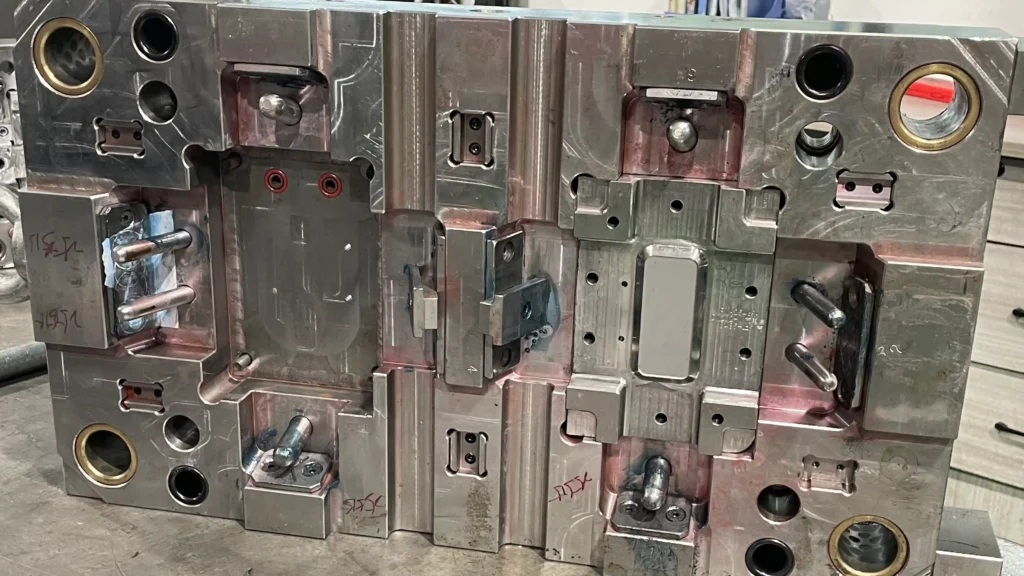

But injection molding tooling is not universal. The molds made for thin and precise mobile phone cases have stricter tolerance requirements than those for large storage boxes. Understanding these differences can ensure that you do not over-invest in unnecessary functions or accept molds that do not meet your needs.

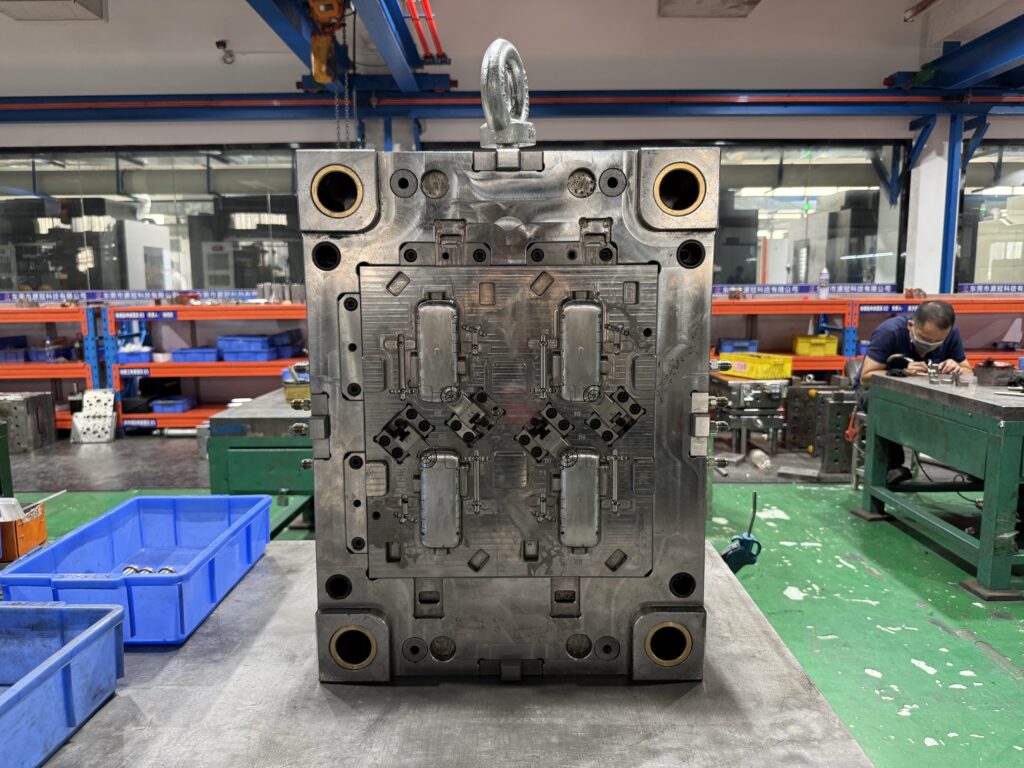

Main Types of Plastic Injection Molds: Classified by Cavity Count

The number of “cavities” (the hollow Spaces that form individual parts) in a mold is the most important factor for production efficiency. It determines how many parts you can produce in each cycle and affects your upfront costs. The following are three key types customized for different business scenarios.

1. Single-Cavity Molds: Your Go-To for Prototypes and Small Runs

2. Multi-Cavity Molds: Scale Efficiently for High-Volume Orders

3. Family Molds: Produce Multiple Related Parts in One Go

4 Core Features of High-Quality Plastic Injection Molds

1. High Precision

Precision refers to the degree of matching between the injection molding tooling cavity and the product design specifications. For you, this is directly related to customer satisfaction: a phone case that is 0.2 millimeters smaller than the standard size will not fit, and a defective electronic housing may ruin the entire device.

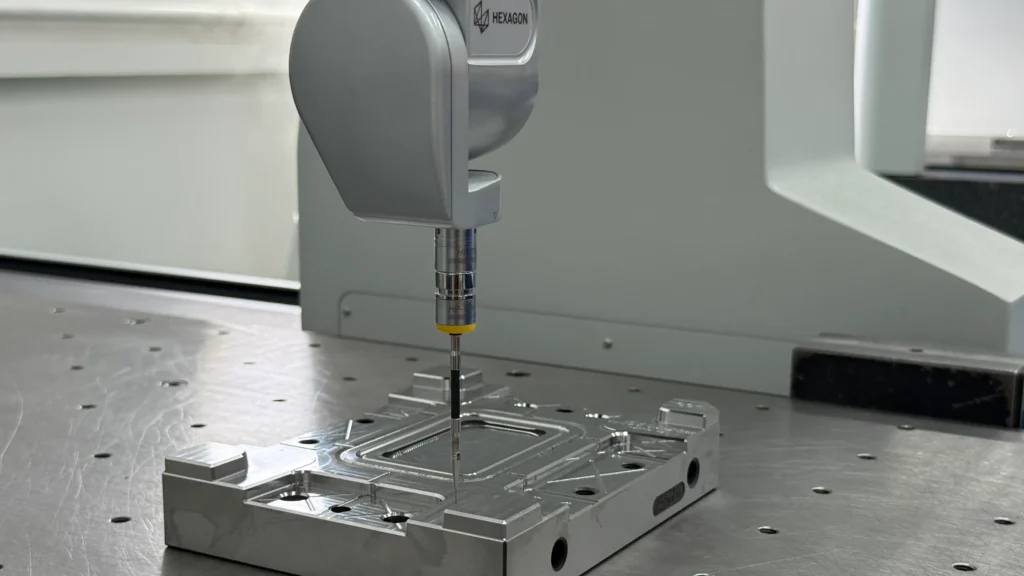

Top-grade plastic injection molding tooling is manufactured with cavities using CNC machining centers and then calibrated with a three-coordinate measuring machine (CMM) to ensure a tolerance of no more than 0.1 millimeters.

Your return on investment: Reduce defective parts (lower waste and rework), and make customers more satisfied. Precision injection molding tools can reduce the return rate of products such as mobile phone cases by 30% or more.

2. Mold Material

Mold Material | Key Advantages | Best For | Lifespan (Production Cycles) |

|---|---|---|---|

Aluminum (6061/7075) | Lightweight, fast to machine, low cost | Prototypes or small runs (1,000-5,000 units) – e.g., new phone case test batches | 50,000 – 200,000 |

P20 Pre-Hardened Steel | Balances cost and durability, easy to polish | Medium runs (5,000-50,000 units) – e.g., standard phone cases, household goods | 500,000 – 800,000 |

Tool Steel (Cr12MoV/SKD11) | Extremely hard, wear-resistant | High-volume runs (50,000+ units) – e.g., best-selling phone cases, automotive parts | 1.5M – 2M |

H13 Hot Work Steel | Heat-resistant, handles high-temperature plastics | Silicone phone cases, thick-walled parts, or heat-sensitive materials | 1M – 1.5M |

Stainless Steel (304/S136) | Corrosion-resistant, superior surface finish | Transparent products (clear phone cases) or food-contact items | 800,000 – 1.2M |

3. Efficient Cooling System

Uneven cooling can lead to warping, shrinkage, and surface defects, thereby slowing down the production speed. Look for injection molding tools with “conformal cooling channels” (shapes that match your product, such as the curves of a phone case) and intelligent temperature control.

This setting ensures uniform cooling, with a cutting cycle time of 30 to 60 seconds for each part.

Your return on investment: Daily output increases by 20%. For instance, optimizing cooling can increase the production of phone cases from 1,000 per day to 12,00 without the need for additional shifts.

4. Customization Flexibility

Your product stands out with its unique design – your injection mold tooling should support this. Whether you need a phone case with a custom texture, two-tone sections, or insert molding (for example, adding a metal clip), flexibility is key.

Reputable suppliers offer end-to-end customization: 3D injection molding tool design visualization, prototype testing, and pre-production adjustments.

3 Benefits of High-Quality Plastic Injection Molds

1. Lower Long-Term Costs

2. Consistent Product Quality

3. Faster Time-to-Market

Key Factors to Choose a Reliable Plastic Injection Mold Supplier

- Technical expertise: Request to review their CNC machines, CMM equipment, and past projects (especially mobile phone case products). Professional experience ensures that they understand your needs.

- Material guidance: They should recommend materials based on your production volume – for example, for small batches of phone cases, use aluminum instead of steel – and do not just recommend high-priced options.

- End-to-end service: Select a supplier that is responsible for design, prototyping, testing, and maintenance simultaneously to eliminate communication gaps.

- Compliance certification: Ensure that the injection molding tool complies with ROHS, REACH, or FDA standards (applicable to food contact parts) to avoid delays in the global market

- After-sales support: Seek suppliers that offer a warranty of over one year and a 24-hour repair response – avoiding downtime is crucial in large orders.

FAQ

Q1: What information do I need to provide for a custom injection mold tooling?

Q2: Can I modify an injection molding tooling after production starts?

Q3: How do I verify a mold’s quality before production?

Q4: How to choose injection mold tooling material for small vs. large runs?

Conclusion

Your tools for injection molding are not merely tools; they are the foundation of product quality and supply chain efficiency. The right injection mold tool can reduce costs, ensure consistency, and bring your products to market faster.

Remember: The best molds are not always the cheapest. It is tailor-made according to your quantity, design, and quality requirements. By focusing on precision, material selection, and reliable suppliers, you will avoid common pitfalls and lay the foundation for the success of your business.

If you are ready to find the perfect plastic injection mold tooling for your project – whether it’s a custom phone case or a large quantity of components – we can offer assistance. The YG team can guide you through material selection, design adjustments, and production schedules. Contact us now.