When purchasing plastic parts from manufacturers, do you often worry about their dimensional accuracy? Have you ever rejected a batch of plastic products because their dimensions deviated from the design requirements?

Today, we will explore the key tool for solving these problems: CMM.

In this guide, you will gain a precise understanding of what CMM is, how it works, and why it is crucial for plastic molding and mold manufacturing – especially for meeting the strict quality standards you value. Let’s start delving deeper.

What Is a CMM Machine?

Table of Contents

ToggleCMM stands for Coordinate Measuring Machine. In simple terms, it is a precision measuring tool that detects the size, shape, and position of the workpiece by moving the probe along three axes (X, Y, Z).

For buyers, the core value lies in verifying whether the plastic parts you purchase meet the precise design specifications. Unlike traditional measuring tools such as calipers or micrometers, the three-coordinate measuring machine offers unparalleled accuracy and reliability.

Have you ever encountered the problem of uneven quality among different production batches? A CMM can eliminate this problem by providing traceable measurement data, thereby ensuring that the quality of each plastic component remains consistent.

How Does a CMM Machine Work?

You don’t need to be an engineer to understand the basic working principle of the CMM machine. Its workflow is very simple and consists of four key steps:

First, place the plastic workpiece on a stable measuring platform.

Then, the machine’s probe (contact or non-contact type) moves along the X, Y, and Z axes to scan the surface of the part.

Next, the probe will collect data points and send them to dedicated software.

Finally, the software will analyze the data and generate a detailed report indicating whether the component meets the design requirements.

The entire process is fast and accurate, even for complex plastic shapes – such as the custom parts required for your products.

Why CMM Matters for Injection Molding & Tooling

Mold development and injection molding are the two most crucial stages in the production process. The CMM machine plays a vital role in both.

During the mold-making stage, a CMM machine verifies the accuracy of the mold cavity, parting surface, and other key components. This ensures that the mold itself is flawless – because a defective mold will only produce defective plastic products.

In the injection molding process, it is used for first Batch Product inspection (FAI)- a requirement of PPAP(Production Part Audit Procedure), and you are likely to need to obtain this service from your supplier. In addition, it will also conduct random inspections during large-scale production to monitor the stability of the products.

Have you ever come across products that do not meet the standards and fail to satisfy the strict quality requirements? CMM machines help manufacturers comply with ISO9001, FDA, and other strict regulations you trust.

The Main Types of CMM Machines for Plastic Parts

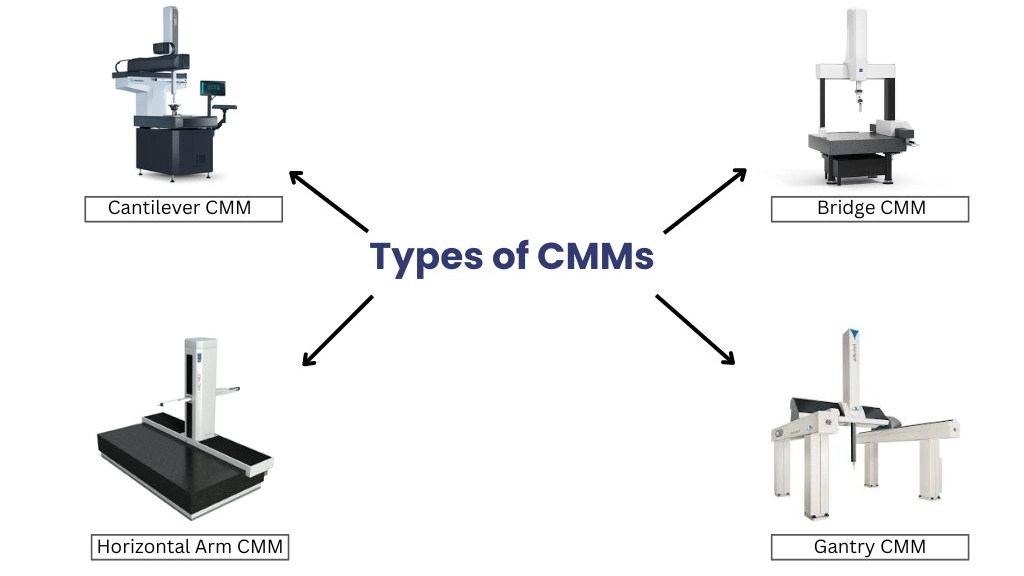

Not all CMM machines are the same. The correct type depends on the plastic parts you purchase. The following are the three most commonly used types, specifically designed for plastic manufacturing:

Advantages and Limitations of CMM Machines

Advantages of CMM Machines

First of all, CMM machines provide outstanding measurement accuracy, which is crucial for verifying precision plastic parts (these parts require strict tolerances). This level of precision directly reduces the risk of product defects entering the production line.

Secondly, they can provide traceable and objective data reports. Unlike traditional manual measurement methods that may be vulnerable to human errors, CMM data is reliable and can be used for quality audits and compliance verifications.

Thirdly, they can adapt well to the complex shapes of plastic parts. Whether your parts have curved surfaces, complex cavities, or multiple features, CMM machines can comprehensively scan and measure them.

Limitations of CMM Machines

Despite these advantages, CMM machine tools also have some limitations that require attention. The most notable one is the high initial investment cost, which means that not all small manufacturers can afford advanced CMM equipment.

In addition, CMM measurement needs to be carried out in a controlled environment. Temperature fluctuations or vibrations, and other factors, may affect accuracy. Therefore, suppliers need to have appropriate facility conditions to ensure the reliability of the results.

Finally, operating the CMM machine requires trained personnel. The lack of skilled operators may lead to measurement errors, even when high-quality equipment is used.

Key Factors to Check When Evaluating a Supplier’s CMM Capabilities

Now that you have understood the importance of CMM machines, how do you evaluate whether the CMM capabilities of plastic suppliers meet your needs? The following are four key factors to consider:

First, match the CMM type with your product. If you need small and precise parts, a bridge-type CMM is sufficient. For large parts, please confirm whether the supplier has a gantry CMM.

Secondly, check the measurement accuracy. Ask the supplier about the precision grade of CMM – ensure it is compatible with your design tolerance (for example, high-precision parts are ± 0.005mm).

Third, verify software compatibility. Ensure that the supplier can generate measurement reports in the format you need (such as PDF or Excel) for internal quality audits.

Fourth, confirm the level of automation. For large-scale production orders, automated CMM can conduct inspections more quickly and obtain more consistent results than manual ones.

Conclusion

In conclusion, the CMM machine is not merely a measuring tool – it is also a guarantee for ensuring the quality of injection molded products. Choosing a supplier that uses CMM machines is the first step to ensuring consistent and compliant plastic parts.

At YG, we specialize in plastic mold manufacturing and injection molding. We use advanced bridge-type three-coordinate measuring machines to inspect molds and plastic parts to ensure they fully meet your specific requirements and global quality standards.

Are you ready to find a reliable plastic injection molding manufacturer? Contact us to talk about your project requirements. We will show you how the quality control process equipped with CMM can support your business.

FAQ

Q1: What’s the difference between a CMM machine and traditional measuring tools?

Q2: Can CMM machines be used for all types of plastic parts?

Q3: How does a CMM machine help meet strict quality standards?

Standards such as ISO9001 and FDA both require strict size control and traceability. The CMM measurement report can provide objective and verifiable data to prove that your plastic parts comply with these standards, thereby avoiding compliance risks.