As a phone case buyer/wholesaler in Europe or the USA, some of you may have faced common pain points with traditional labeling: silk-screened designs scratch off, adhesive stickers peel, and non-recyclable materials fail EU REACH or US CPSIA standards. IML (In-Mold Labeling) solves these issues by fusing labels into phone cases during manufacturing—creating a permanent, durable finish.

This guide breaks down IML for your business, utilizing industry-proven insights to help you determine if it’s the right fit for your needs.

What is In-Mold Labeling(Tailored for Phone Cases)

Table of Contents

Toggle- A smooth finish that fits curved surfaces (e.g., iPhone/Samsung rounded edges) without peeling.

- Alignment with industry trends: 32% of durable phone cases in Europe and the USA used IML in 2024, per market data, with an 18% annual growth rate.

Why the IML Process Works for Your Phone Case Business

1. Unmatched Durability

- They pass 5,000 scratch tests (meeting ASTM standards) and withstand moisture (humid climates) and temperature swings (-20°C to 60°C), reducing returns from your retailers.

2. Customization for Shelf Appeal

3. EU/USA Compliance

4. Cost Efficiency for Bulk Orders

How does In-Mold Labeling Work: Step-by-Step

1. Label Preparation: Pre-print PP/PET films with UV-curable ink (fade-resistant) and cut to match phone case designs.

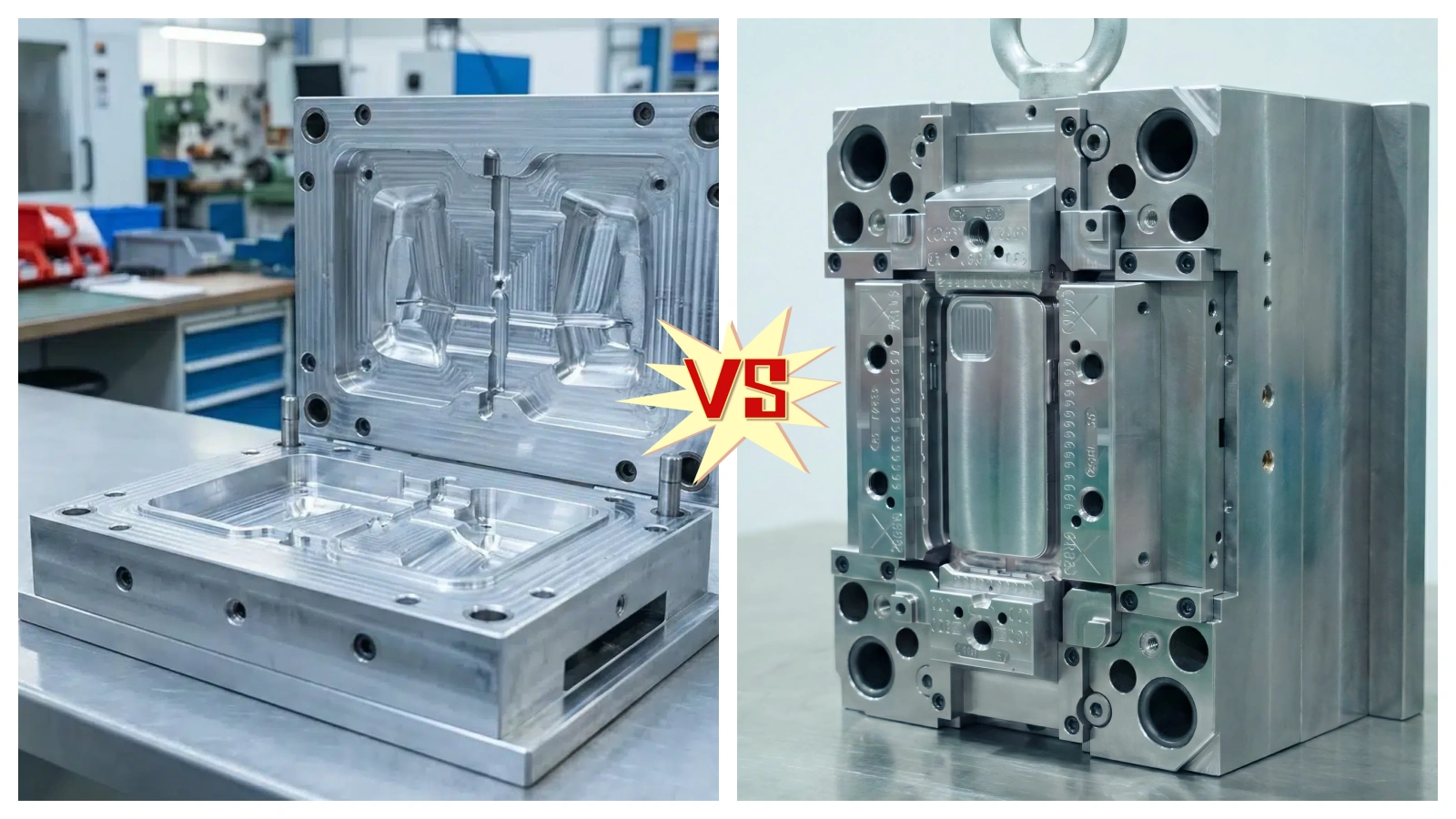

2. Mold Setup: Secure labels inside a precision mold (±0.05mm accuracy) using static or clamps to avoid shifting.

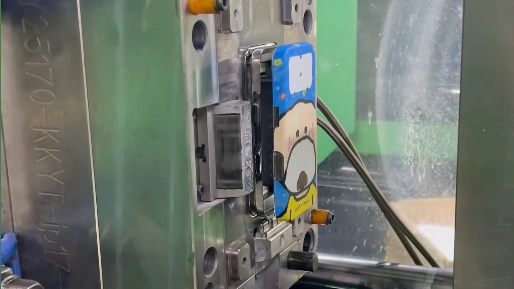

3. Injection & Fusion: Inject molten plastic (PP, PC, or TPU—all compliant) at 180–220°C. The plastic fuses with the label as it cools.

4.Cooling & Quality Check: Cool for 10–15 seconds, then test for label alignment, adhesion (tape test), and scratch resistance before packaging.

IML vs. Traditional Labeling

| Factor | IML Process | Silk-Screening | Adhesive Stickers |

|---|---|---|---|

| Durability | 5,000 scratch tests; no peeling | 1,500 scratch tests; fades fast | 500 scratch tests; peels in 3–6 months |

| Customization | Full-color 300DPI; fits curves | 1–2 colors; edge blur on curves | Full-color but low precision; wrinkling |

| EU/USA Compliance | 100% recyclable; REACH/CPSIA certified | Risk of heavy metals in ink | PVC glue fails recycling standards |

| Unit Cost (10k+ units) | $0.8–$1.2 | $0.9–$1.4 | $0.7–$1.1 (3% defect rate) |

| Production Cycle | 7–10 days (including sampling) | 10–14 days | 8–12 days (plus labeling time) |

What is the Difference between IML and lMD?

| Dimension | IML (In-Mold Labeling) | IMD (In-Mold Decoration) |

|---|---|---|

| Core Definition | A pre-printed label film is fused to the product surface during molding, becoming part of the case. | A decorative ink layer or film is transferred/embedded into the product during molding (subtypes: IMR, IMF). |

| Decoration Layer Location | The label sits on the outer surface of the phone case (direct contact with hands/objects). | Decorative layer is often embedded under a clear plastic topcoat (protected from wear). |

| Key Materials | PP/PET label films (matched to case material for recyclability). | Ink layers, PET base films, or clear protective films (e.g., PC for scratch resistance). |

| Customization Flexibility | Ideal for high-resolution graphics, logos, and textured finishes (e.g., matte / glossy). | Excels at complex effects: 3D textures, metallic sheens, or “touch-sensitive” decorative layers. |

| Durability for Phone Cases | High—label is fused to the surface, resisting scratches (5,000+ tests) and fading. | Higher for embedded designs (IMR/IMF): decorative layer is protected by topcoat, but outer films can still wear. |

| Cost (Bulk Orders) | Lower upfront cost—pre-printed labels are simpler to produce. | Higher upfront cost—requires custom ink/film setups, but competitive for large volumes. |

| Phone Case Use Cases | Everyday protective cases, brand-logo focused designs, budget-friendly B2B lines. | Premium cases (e.g., luxury brands), cases with 3D textures, or designs needing long-term UV resistance. |

Quick Takeaway for phone case brands:

How to Choose an IML Phone Case Supplier

- IML Expertise: Choose suppliers with experience in 3C accessories (not just generic IML) to handle phone case precision.

- Compliance Docs: Ask for REACH, CPSIA, and CE certificates—non-negotiable for EU/USA imports.

- Sampling Support: Look for free samples (3–5 day turnaround) to test design fit and durability before bulk orders.

- Quality Control: Ensure suppliers run alignment, adhesion, and scratch tests—critical for consistent B2B quality.

Our IML Phone Case Services

- Process Options: Focus on injection molding IML (most suitable for phone cases), compatible with PP, PC, and TPU materials.

- Compliance Support: Provide REACH, CPSIA, and CE documentation for every order to simplify customs clearance.

- Customization: Support high-resolution (300DPI) designs for curved/slim phone cases, with design optimization for IML compatibility.

- Sampling & Quality: Offer small-batch sampling (to test market demand) and 3-step quality checks (alignment, adhesion, scratch resistance) for bulk orders.

FAQ: IML Phone Case Questions

Yes—IML labels can include hidden QR codes or holographic elements, as supported by industry IML capabilities.

Yes—label and case materials are identical, making them EU WEEE and US EPR compliant for standard plastic recycling.

We offer flexible MOQs, starting with small batches to help you test EU/USA market demand—common for B2B IML production.

Ready to Explore IML for Your Phone Case Business?

- Submit your IML phone case request (share target model, design, and quantity) for a free quote.

- Get a sample within 3–5 days to test fit and durability.