Are you struggling with the weld line in injection molding? This common weld line defect not only affects the appearance, but it may also weaken the product’s strength, prevent it from passing strict quality certifications, and damage your market competitiveness.

In this guide, you will learn about the root causes of weld formation, the impact they have on your products, and actionable injection molding weld line solutions to eliminate or minimize such problems.

What Is Weld Line in Injection Molding

Table of Contents

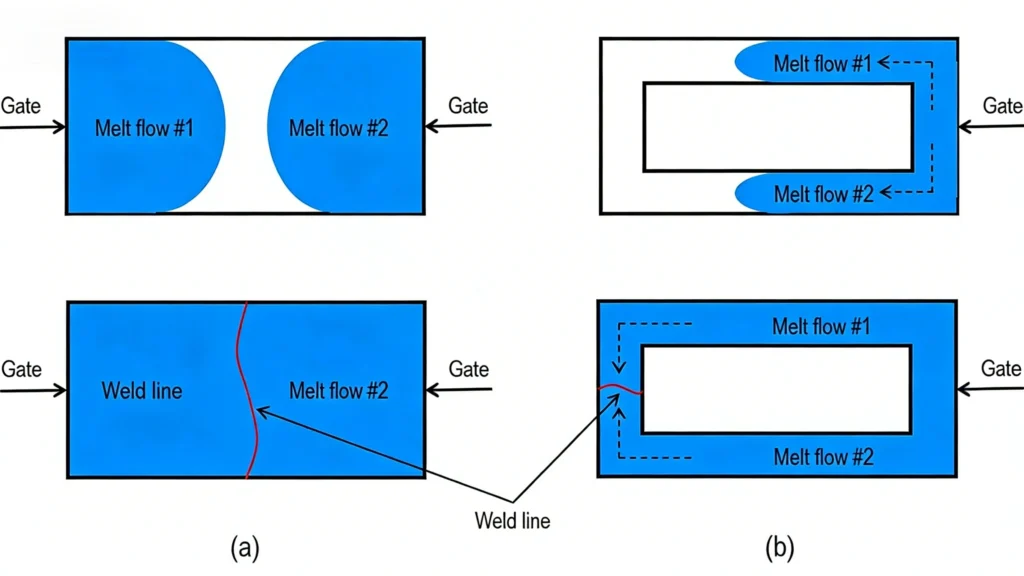

ToggleWeld lines, also known as fusion lines or bonding lines. Among the types of injection molding defects. Weld line is a common and significant defect. It refers to: when two or more streams of flowing molten plastic meet in the mold cavity and attempt to fuse, a visible, usually linear or V-shaped dent or pattern forms on the surface of the plastic part due to insufficient fusion.

This defect is common in complex-shaped parts, components with multiple injection gates, or thin-walled plastic products.

What Causes Injection Molding Weld Lines

Weld lines do not occur randomly – they are triggered by specific factors related to materials, mold design, or processing parameters, and these factors may also lead to different weld line types. Understanding these causes is the first step to solving the problems encountered in the project.

1. Material Factors

The properties of the thermoplastic material you use play a crucial role. If the material has poor melt flow performance, high crystallinity, or uneven molecular weight distribution, it is more likely to form weld lines because its melt flow is difficult to fuse smoothly together.

Temperature and humidity also play important roles. If the material is too cold when entering the injection mold or contains too much moisture (this situation is common in materials such as PA or PC), the melt flow will cool down too quickly, thus failing to achieve proper fusion.

2. Mold Design Factors

Mold design is another key factor. Improper gate position or insufficient number of gates can cause the molten plastic to split into multiple streams, increasing the probability of weld lines.

A poorly designed runner system can lead to excessive pressure loss, thereby weakening the strength of the molten flow before convergence. Complex component geometry – including transition zones or dead zones between thick and thin walls – can also disrupt flow and hinder the fusion process.

Insufficient ventilation is also a common cause. The air retained in the mold will prevent the molten plastic from filling the cavity and fusing, directly resulting in the weld line.

3. Processing Parameter Factors

Even with the right materials and molds, incorrect processing parameters may still lead to the formation of weld lines. Slow injection speed or insufficient pressure means that the molten plastic lacks enough kinetic energy to fully fuse.

A lower mold temperature will cause the melt to cool rapidly upon contact, thus forming a solid layer that hinders the normal process of fusion. In addition, inappropriate screw speed or back pressure Settings may also lead to poor plasticizing effects, making it more difficult for the melt flow to achieve effective bonding.

How Do Weld Lines Impact Your Plastic Parts

When quality, safety, and aesthetics are uncompromising, weld lines pose significant risks. Understanding these effects will help you choose the solution.

Structural Integrity Risks

Weld lines will weaken the structure of the component because they will form a part with lower tensile strength and impact resistance. This is particularly dangerous for high-stress application scenarios, such as automotive parts or medical devices.

Components with Weld lines may fail under normal use, resulting in product recalls, safety liability, and damage to brand reputation in the competitive market.

Appearance Defects

Weld lines are one of the most significant visual defects on the surface of plastic parts, affecting the product’s aesthetic appeal, especially for products with high appearance requirements (such as consumer electronics casings and automotive interior parts).

Even minor weld lines can undermine the visual appeal of high-end products, thereby reducing their market value.

Functional & Cost Implications

Weld lines may also affect the normal functioning of the functionality. For waterproof or airtight components, they may reduce the sealing effect. In addition, welding marks may also damage the surface finish and coating adhesion, thereby reducing the effectiveness of subsequent processing steps.

From a cost perspective, Weld lines will increase the scrap rate and rework costs. They may also cause production delays, disrupt delivery plans, and affect relationships with time-sensitive customers.

How to Identify & Inspect Weld Lines in Your Parts

Start with visual inspection – this is the simplest method. Inspect your components under good lighting conditions to detect linear marks, color changes, or rough spots. This conforms to the conventional quality control process adopted by most manufacturers.

If more rigorous tests are required, advanced techniques should be adopted: microscopic analysis to check the quality of fusion, tensile or impact tests to assess structural strength, and surface roughness measurements to quantify aesthetic defects.

Be sure to refer to the relevant industry standards. For automotive components, the ISO10360 standard should be followed. These standards define the acceptable weld lines in the weld lines inspection standards for automotive parts and other industries.

Solutions to Eliminate or Minimize Weld Lines

The good news is that you can solve most weld line issues through targeted adjustments. The following are specific and feasible solutions for eliminating or minimizing the influence of the weld line in injection molding.

Optimize Your Materials

Select thermoplastic materials with better melt flow characteristics – this helps the melt flow to fuse more easily. Please consult your material supplier to select grade materials that meet the component requirements, thereby reducing the risk of injection molding weld lines.

Add appropriate nucleating agents or plasticizers to improve the fusion effect. At the same time, ensure that the material is properly dried and preheated – this can remove moisture and ensure that the material enters the mold at the optimal temperature.

Improve Mold Design

Optimize the position of the mold gate and increase the number of gates when necessary – this helps ensure that the molten plastic can flow evenly and fuse at the best position. Redesign the runner system to minimize pressure loss and maintain consistency in melt flow.

Enhance the mold exhaust to release the trapped air. You can also modify the geometry of the parts to avoid thick and thin transitions and dead zones, ensuring smooth and uninterrupted fluid flow.

Adjust Processing Parameters

Increase the injection speed and pressure to provide the kinetic energy required for the molten plastic to fully fuse. Increase the temperature of the mold and material to slow down cooling and promote better merging of the melt flow.

Optimize the screw speed and back pressure to improve the plasticizing effect. For complex parts, sequential valve gates can be considered – this can control the time of melt injection, thereby reducing the formation of weld lines.

Post-Processing Treatments

For components that are crucial to appearance, post-treatment processes such as grinding, polishing or painting should be adopted to cover up minor welding marks. These methods are particularly applicable to consumer-oriented products.

How to Avoid Weld Lines in Injection Molding

Preventing weld lines is more effective than fixing them. Incorporate these measures into the project planning to avoid problems in the early stage.

Participate in the collaboration on design for manufacturability (DFM) at the early stage of the project. Collaborate with mold designers and injection molding engineers to identify and modify structures that are prone to generating weld lines before production begins.

Use mold flow simulation (CAE) to predict weld line positions. This software enables you to conduct virtual tests on different gate design materials and processing parameters, allowing you to make corresponding adjustments before making molds.

Establish standardized production process flows: Create the best parameter libraries for different materials, conduct regular mold maintenance, and provide training on weld line detection and prevention to the production and quality control teams.

Conclusion

weld line in plastic injection molding is a common but solvable problem – especially when you have the corresponding expertise and solutions. By addressing factors related to materials, molds, and processing, and integrating preventive measures such as DFM and mold flow simulation, high-quality components that meet global standards can be produced. This is the key to comprehensively alleviating the defects of injection molding.

At YG, we specialize in providing precision mold and injection molding solutions. Our team has extensive experience in weld line elimination and possesses the ability to optimize the entire process of a project from design to production from a technical perspective. We are well aware of the strict quality requirements and will work closely with you to ensure compliance and the success of the project.

Please contact YG today to discuss your injection molding project and obtain a customized quotation.