In the competitive landscape of smartphone casing manufacturing, selecting the optimal production technology has a direct impact on product quality, cost efficiency, and market response capabilities. For brand owners and wholesalers, the choice between two-shot injection molding and overmolding usually determines their ability to balance innovation and scalability.

This guide provides a technical comparison of these processes to help you align your production strategy with your business goals, whether you are targeting consumers with seamless designs or a startup that requires flexible production.

What is Two-Shot Injection Molding?

Table of Contents

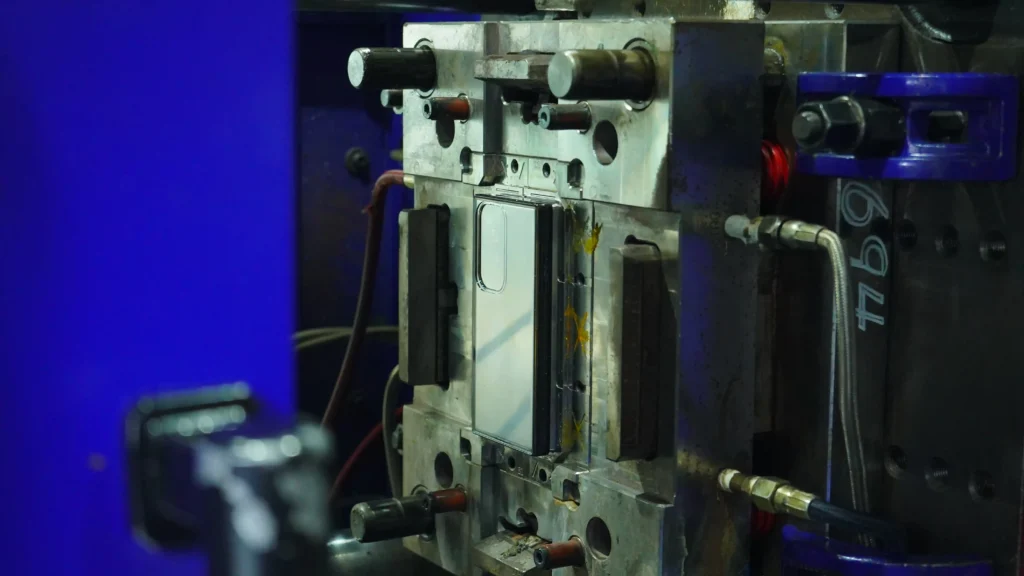

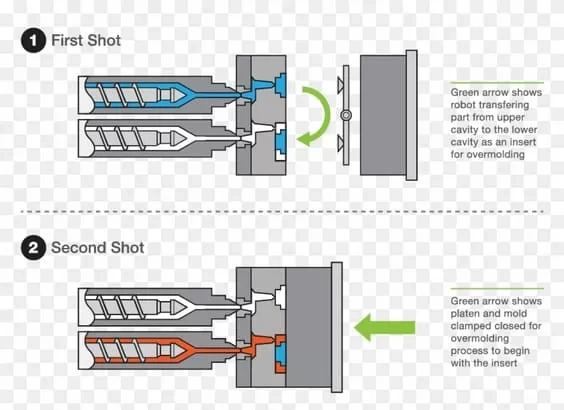

ToggleTwo-shot injection molding is also known as double-shot, multi-shot, or dual-shot molding. a single-cycle, multi-material process that integrates two distinct materials (e.g., PC and TPU) into one component using a specialized dual-barrel machine. The process unfolds in two stages:

- First shot: The base material (e.g., rigid PC for structural support) is injected into a mold cavity.

- Second shot: The base material is loaded into a second mold, where materials (such as soft silicone or TPU) are injected to enhance grip, color, or texture.

This method eliminates post-assembly steps, ensuring seamless integration and enhanced structural integrity—ideal for cases requiring a perfect balance of rigidity and flexibility.

What is Overmolding?

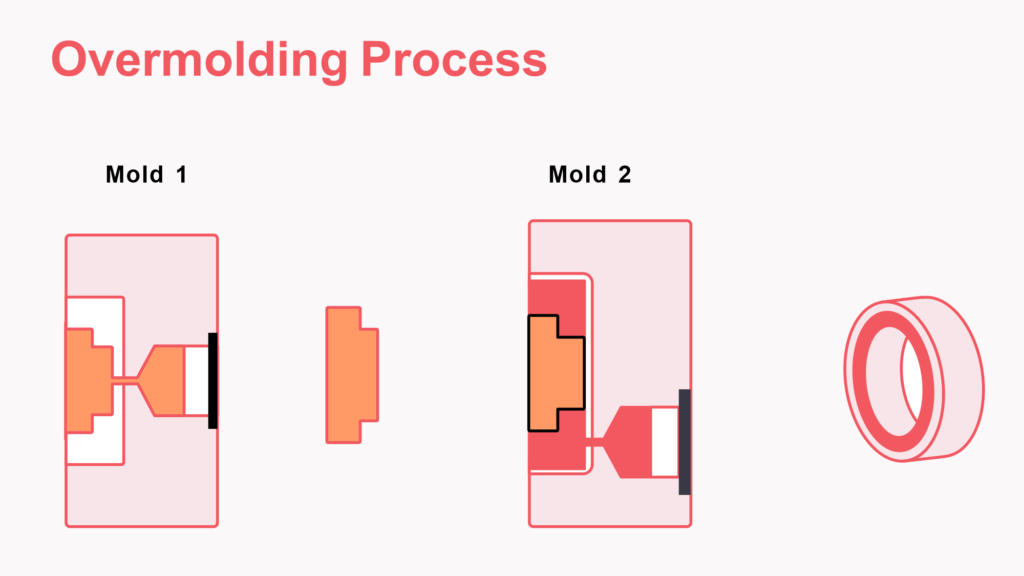

Overmolding is a two-step process. First, the base material (basic component) is formed, and then it is placed in a second mold, and a layer of plastic is injected. Unlike two-shot molding, the substrate and overmold are produced in separate cycles, allowing greater flexibility in material selection (e.g., combining metal, wood, or 3D-printed bases with TPU).

Key steps include:

- Substrate production: Manufacture the core component (e.g., a hard plastic frame) using standard injection molding or machining.

- Overmold injection: The substrate is loaded into a second mold, where the coated material (e.g., soft silicone or TPU) is injected to add grip, color accents, or texture.

This versatility makes overmolding popular for custom designs, such as cases with ergonomic grips or brand logos embedded in contrasting colors.

Two-Shot Molding vs Overmolding: A Technical Comparison

1. Production Efficiency & Cost

| Metric | Two-Shot Molding | Overmolding |

|---|---|---|

| Cycle Time | Fast (single machine, no post-assembly) | Slower (two separate cycles, potential delays) |

| Tooling Cost | High (specialized dual-cavity molds) | Lower (standard single-cavity molds for each step) |

| Labor Requirement | Low (automated, minimal human intervention) | Moderate (substrate handling between molds) |

| Suitable Volume | High-volume (10,000+ units/run) | Low-to-medium volume (500–5,000 units/run) |

Insight: Two-shot molding excels in mass production, where high upfront mold costs are offset by faster throughput. Overmolding, with lower initial investment, suits startups or seasonal lines requiring frequent design changes.

2. Material Compatibility & Bond Strength

- Two-shot molding: Bonds materials at the molecular level, creating a permanent, water-resistant seal—critical for rugged cases needing IP67/IP68 protection.

- Overmolding: Relies on mechanical interlock (e.g., grooves in the substrate) or chemical adhesion. While sufficient for most consumer cases, it may fail under extreme stress compared to two-shot bonds.

Example: A military-grade phone case designed for drops benefits from two-shot PC+TPU bonding, whereas a fashion-focused case with interchangeable overmold colors uses overmolding for cost efficiency.

3. Design Flexibility

Two-shot molding: Limited by mold complexity; best for symmetrical designs with consistent material distribution (e.g., slim cases with TPU edges and PC backs).

Overmolding: Supports complex geometries, including undercuts, varying thicknesses, and mixed materials (e.g., wood-grain PC substrates with neon TPU accents). It enables color mixing and texture experimentation without retooling the entire mold.

Real Applications: Case Studies

Case 1: Premium Brand Uses Two-Shot Molding for Seamless Durability

A leading smartphone accessory brand has launched a best-selling “seamless molding” phone case series, targeting consumers who pursue simple design and excellent drop protection. Requirements include:

- 0.8mm ultra-slim profile

- Scratch-resistant PC back + shock-absorbing TPU edges

- 100,000-unit monthly production

Solution: Two-shot molding delivered:

99.8% defect-free rate (no delamination)

30% faster time-to-market vs. overmolding

A seamless aesthetic justifying a $59.99 retail price point

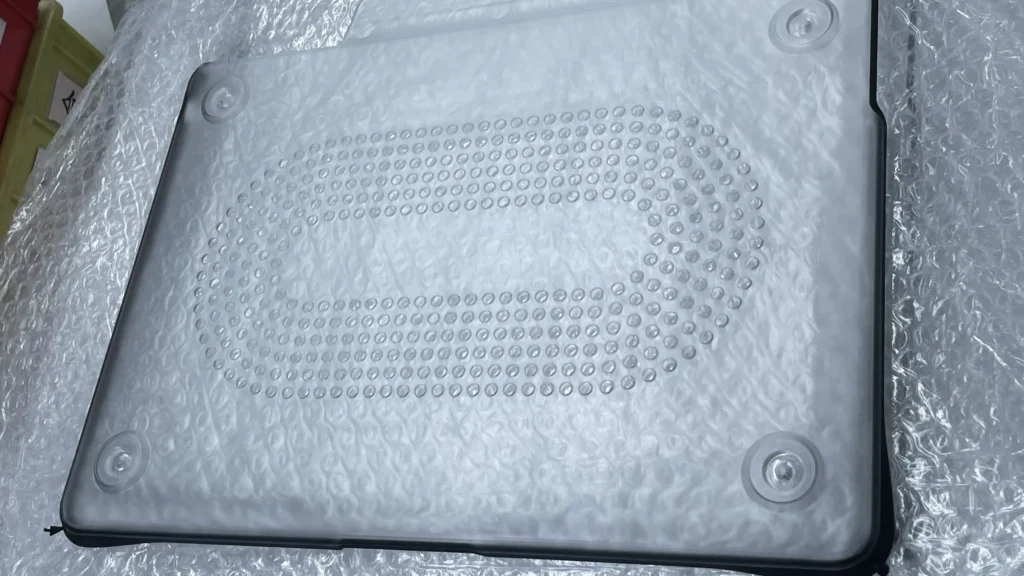

Case 2: Startup Leverages Overmolding for Customization

A start-up company specializing in the production of laptop cases tested five unique designs and carried out small-scale production (1,000 of each). Main requirements:

- Rapid iteration (design changes within 2 weeks)

- Budget control (<$10,000 in tooling)

- Meet the minimum order requirement of 1,000 small quantities

Solution: Overmolding allowed:

Low-cost prototype molds for each design

Mix-and-match of PLA colors and TPU textures

30% lower upfront investment vs. two-shot tooling

How to Choose the Right Process for Your Business

Choose Two-Shot Molding If:

You prioritize high-volume production (10,000+ units/run).

Seamless and molecular-level bonding are critical (e.g., waterproof case).

Long-term cost efficiency outweighs high initial tooling expenses.

Choose Overmolding If:

You need low-volume flexibility or frequent design iterations.

Material experimentation (e.g., metal-TPU or wood-silicone combinations) is key to your brand.

Budget constraints require minimizing upfront tooling costs.

Get Customized Injection Molding Solutions at YG

Understanding the nuances between two-shot molding and overmolding is just the first step. To turn your design vision into reality, partner with YG—your dedicated expert in precision injection molding with 30+ years of industry leadership.

Why Choose YG?

- End-to-End Expertise: Our team of 30+ designers, 15 mold engineers, and 20+ project specialists guides you from DFM analysis to material selection, ensuring optimal (process) alignment for your project goals.

- Advanced Capabilities: Equipped with 2 two-shot machines and 137 standard injection units, we handle both high-volume production (e.g., 300,000+ units/month for consumer electronics) and Flexible customization for small-batch orders.

- Quality & Compliance: Certified to ISO 9001 and ISO 14001 standards, we guarantee <0.5% defect rates and full compliance with RoHS/FDA requirements, backed by precision testing (CMM, tensile strength analysis).

Whether you need two-shot efficiency for complex geometries or overmolding flexibility for soft-touch applications, YG streamlines your journey from design to delivery. Upload your CAD files today for a free instant quote, and let our engineers tailor the perfect solution for your project.

Conclusion

Two-shot injection molding and overmolding are powerful tools for smartphone case manufacturers, each with distinct advantages for different market segments. For the phone case brands, the choice hinges on production volume, design complexity, and long-term cost goals:

- Two-shot molding is the gold standard for premium, high-volume production, delivering unmatched efficiency and bond strength.

- Overmolding empowers flexibility, making it perfect for startups, custom designs, or low-volume runs.

By aligning these techniques with your orientation—whether high-end durability or innovative customization—you can optimize production, reduce waste, and deliver products that resonate with your target audience.

Ready to transform your phone case line? Contact us for a free consultation on material selection, tooling optimization, and scalable manufacturing solutions tailored to standards.