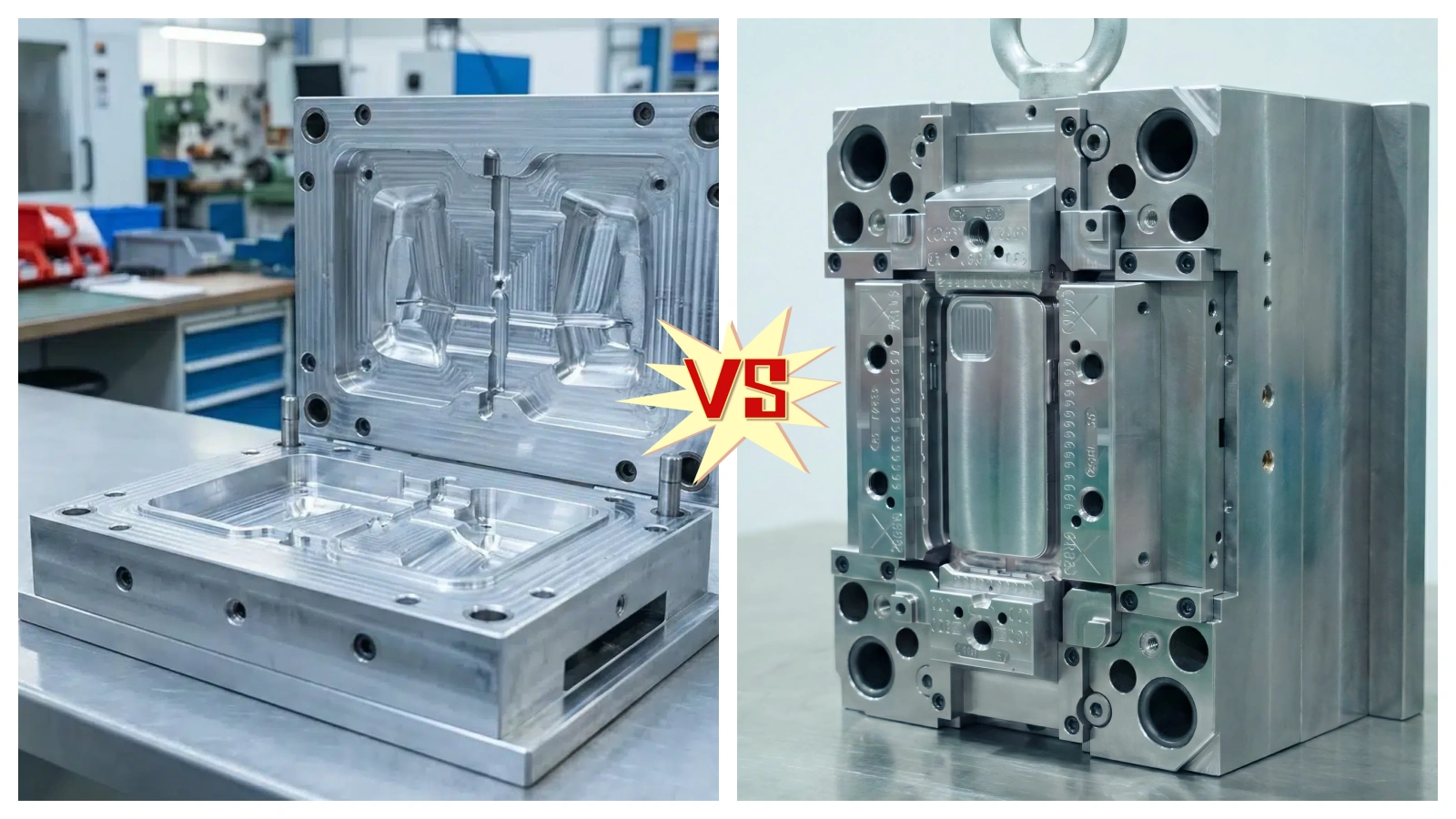

In the global manufacturing landscape, plastic injection molding processes provide fundamental support for the production of countless components in industries such as automobiles, medical care, electronics, and consumer goods.

With the surging demand for precision, efficiency, and customization, Chinese plastic injection molding manufacturers, with their advanced technology, mature industrial chain, and comprehensive service capabilities, can effectively meet the needs of international customers. This guide highlights 11 top Chinese manufacturers to help you find the ideal partner that meets your project requirements.

11 Excellent Chinese Plastic Injection Molding Manufacturers

Table of Contents

Toggle1. YG Tech

2. Rilong

As a trusted leader in one-stop plastic injection molding solutions, YG Tech has established a strong global reputation with over 30 years of expertise:

1. Company Foundation and global layout

YG Tech was founded in 1996, and its headquarters are located in Dongguan, China. The company operates two manufacturing bases with a total area of over 40,000 square meters and more than 800 employees, laying a solid foundation for large-scale production.

To better serve global customers, the company has established offices in Shenzhen (China), the United States, Sydney, and Melbourne, providing end-to-end support from design to delivery in over 30 countries around the world.

2. Technical accuracy and R&D capabilities

YG Tech excels in the field of precision manufacturing, with an accuracy of up to ± 0.01 millimeters. This is attributed to its high-end equipment, such as Mikron/MakinoCNC machine tools and Sumitomo/Haitian injection molding machines.

The team holds over 80 invention patents, and more than 100 experienced engineers are driving continuous technological innovation to meet the constantly changing industry demands.

3. Production capacity and delivery efficiency

YG’s mold manufacturing center has a strong production capacity and can produce over 150 sets of molds every month. Its injection molding base is equipped with over 130 advanced devices and can produce more than 3 million products every month.

4. Core business and Target industry

It mainly serves key industries, including consumer electronics, smart devices, industrial equipment, medical devices, and the Internet of Things. As a professional custom injection molding manufacturer, it focuses on plastic injection molding, two-shot molding, insert molding, and overmolding, supporting 50+ plastic injection molding materials such as PC/ABS/TPU.

5. One-stop service and flexible production

YG Tech’s one-stop turnkey service covers the entire process from product design (ID/MD, DFM analysis), prototype making, mold making, and mass production to post-processing. This integrated mode can simplify the workflow and significantly reduce the cost of multi-link connections.

Flexible production is another highlight: it offers rapid delivery for small batches, adjustable capacity for large orders, and a 24-hour response to customers’ production demands.

6. Quality Control and Certification

YG has a quality control team of over 100 members, implementing strict management from IQC (Incoming Quality Control) to OQC(Outgoing Quality Control) to ensure the consistency of product standards.

It also holds multiple authoritative certifications, including ISO9001, ISO14001, ISO13485, GRS4.0, and SMETA, fully meeting the standards of the global market. The company has served over 1,000 global customers, demonstrating its ability to provide stable and high-quality products for complex custom components.

Founded in 1990 and headquartered in Shenzhen, Rilong is a state-recognized high-tech enterprise with more than 30 years of industry experience.

Core business: Focus on high precision plastic injection molding, supplemented by one-stop supporting services: mold manufacturing, CNC machining, surface treatment, and OEM assembly. The company is equipped with over 600 advanced machines (Sumitomo Corporation /JSW) and a dust-free workshop, specializing in the production of small, high-precision components such as lenses and automotive electronic parts.

Service industries: Serving the automotive, medical, and consumer electronics industries, with 80% of its customers coming from the United States and Europe, covering over 50 countries worldwide.

Main advantages: With rich experience in high-precision manufacturing, mature overseas service capabilities, and authoritative certifications (ISO9001, IATF16949, FDA)- this makes it a trusted Chinese injection molding manufacturer that meets the high standards of global buyers.

3. TK Group

As a listed leader in the one-stop plastic injection molding field, TK Group has established a global industrial layout.

It operates four production bases in Shenzhen, Huizhou, Suzhou (China), and Vietnam, with a total area of 180,000 square meters and over 4,000 employees, including more than 300 designers.

Core business: Focusing on one-stop plastic injection molding solutions, covering injection mold design/manufacturing as well as the production of injection molded components. In addition, the company also offers specialized services such as insert injection molding, multi-color injection molding, IML injection molding, and secondary processing.

Service industries: automotive, medical and personal care, commercial communication equipment, mobile/wearable devices, and smart home products.

Main advantages: Rich industry experience, global production layout, comprehensive service capabilities, and multiple authoritative certifications (ISO9001, IATF16949, ISO13485)- this ensures that, as a Chinese injection molding manufacturer, it can provide reliable services to global buyers.

4. HanKing Mould

HanKing Mould was founded in 1996 and is headquartered in Longgang District, Shenzhen City. It is a custom injection molding manufacturer with over 25 years of experience, specializing in custom plastic molds and the injection molding business.

Core business: Provide one-stop plastic injection molding solutions, covering custom mold design, mold manufacturing, mold testing, injection molding, quality control, as well as subsequent processes such as spraying and screen printing.

Service industries: Automotive, electronics, home appliances, and medical industries, providing precision tools, 2K molds, and custom-formed components to meet the diverse needs of various industries.

Main advantages: Possessing professional one-stop service capabilities, strict all-round quality control, and authoritative certification qualifications (TS16949, ISO9001, ISO14001).

5. Richfields

Richfields was founded in 2001, with its headquarters located in Dongguan. It has over 20 years of experience in plastic parts and mold manufacturing, producing more than 300 molds annually, and is currently expanding into the US market.

Core business: Covering precision plastic injection molding and mold manufacturing, while providing one-stop services: prototype making, reverse engineering, secondary processing (painting, screen printing, hot stamping), and final assembly. The company is also proficient in special processes such as large part molding, overmolding, and gas assist molding.

Service industries: automotive, consumer goods, furniture, and industrial sectors, product range from automotive parts to plastic furniture and electronic enclosures.

Main advantages: Located in the strategic location of Dongguan, it possesses full industrial chain service capabilities, has global export experience (targeting the United States, Europe, and Brazil), and holds authoritative certifications (ISO9001, IATF16949, FDA, and Disney-certified supplier).

6. SeaskyMedical

With over ten years of industry experience, SeaskyMedical is an ISO-certified medical injection molding manufacturer, equipped with Class 7 and Class 8 cleanrooms that meet strict medical industry standards.

Core business: Focusing on one-stop medical plastic injection molding solutions, covering product design/development, mold design/manufacturing, material selection, injection molding, and secondary processing (assembly, packaging), etc. The company performs particularly well in special processes such as micro injection molding, medical insert molding, and overmolding.

Service industry: Specializing in the medical and pharmaceutical industries, producing custom mold products, including medical casings, equipment components, plastic medical consumables, and laboratory consumables, etc.

Main advantages: Possessing ISO 13485 certification, professional cleanroom production capacity, rich knowledge of medical materials, micro molding expertise, and rapid delivery capability, all of which ensure the provision of safe and reliable services to medical customers.

7. HITOP

HITOP has 21 years of industry experience, and its headquarters is located in Chang’an, Dongguan. As a leading injection mold manufacturer in China, the company has 40 experienced designers and an annual production capacity of over 800 injection molds.

Core business: It covers one-stop plastic injection molding solutions: mold design/engineering (including mold flow analysis), mold manufacturing, rapid prototyping, injection molding, die casting (160T-850T models), as well as secondary processing and assembly, and is supported by advanced processing machinery.

Service industries: diversified high-end fields such as automotive, medical, electronics, household appliances, and aviation, and maintain stable cooperation with global customers such as Electrolux.

Main advantages: Possessing professional full-service capabilities, expertise in large-scale mold manufacturing, reliable quality control, and personalized customer support, it ensures the efficient delivery of complex projects.

8. Ecomolding

Ecomolding is a professional plastic injection molding and mold manufacturing company. It has a factory covering an area of over 2,000 square meters located in Shenzhen, China. The company has more than 100 employees and a monthly production capacity of 40 to 50 injection molds. It is also equipped with advanced equipment from Switzerland and Taiwan.

Core business: Covering high-precision plastic injection molding and custom mold manufacturing, while providing one-stop services: mold design, prototype making, secondary processing (painting, screen printing, assembly), and internal quality inspection. The company excels in the production of optical components and IML processes in specific application fields.

Service industries: Automotive, home appliances, electronics, and general industrial OEM industries, dedicated to providing customized solutions for small and medium-sized customers worldwide.

Main advantages: Transparent factory pricing, ISO9001 certified quality standards, all-round service capabilities for small and medium-sized enterprises, experienced sales managers well-versed in engineering technology, and advanced imported equipment, all of which ensure the stability of production.

9. FOW Mould

Founded in 1978, FOW Mold is a high-tech enterprise in Taizhou city, Zhejiang Province, with 40 years of industry experience. The company has an annual production capacity of 900 molds and holds an ISO9001 certification.

Core business: One-stop plastic injection molding solutions covering plastic product/mold design, mold making, injection molding, 3D printing, CNC machining, insert molding, and overmolding.

Service industries: warehousing and storage, baby products, furniture, automobiles, household appliances, and other fields, and has a global business network covering Europe, America, and other regions.

Main advantages: Rich industry experience, one-stop full-chain service capabilities, strict quality control, intellectual property protection (confidentiality agreement), and cost-effective solutions trusted by global customers.

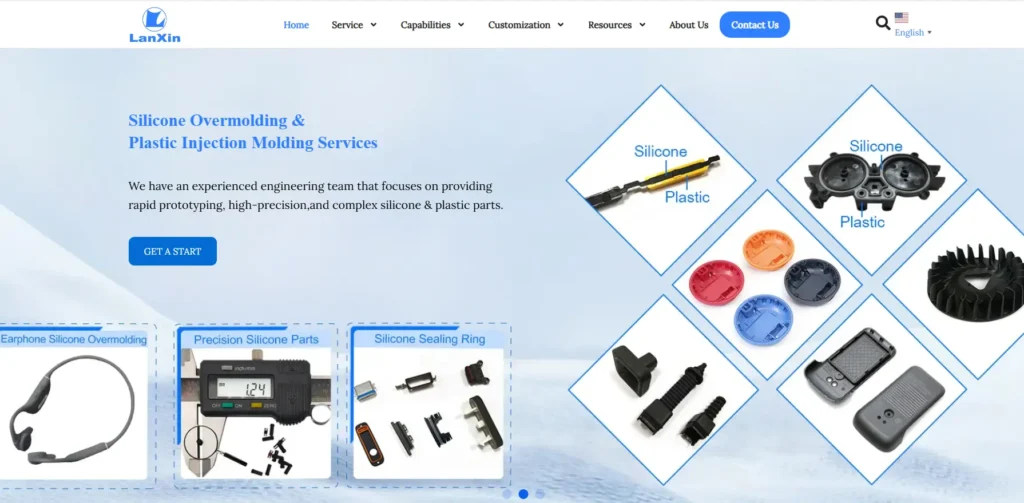

10. Lanxin

Lanxin was founded in 1997, with its headquarters located in Dongguan, China. It has over 28 years of experience. The company has multiple factories in the Chinese mainland, Thailand, and Vietnam, and holds certifications such as ISO13485, IATF16949, and ISO9001.

Core business: OEM/ODM services covering plastic injection molding, silicone rubber and die-cut products, and providing one-stop solutions such as mold design/manufacturing, LSR molding, rapid prototyping, and secondary processing (painting, electroplating, etc.).

Service industries: Automotive, medical, and consumer goods industries. They have established long-term cooperative relationships with well-known brands such as HUAWEI, FOXCONN, and MOLEX.

Main advantages: Full-process one-stop service, multi-regional production layout, strict quality control, intellectual property protection, and providing efficient and customized services for global customers.

11. First Mold

First Mold was founded in 2011 and is headquartered in Zhongshan, China. It is a high-tech injection mold manufacturer with three production bases (two in China and one in Mexico) and a factory in China covering an area of more than 30,000 square meters.

Core business: Focusing on one-stop solutions, covering areas such as high-precision mold manufacturing, plastic injection molding (with a tolerance of ± 0.01 mm), die casting, CNC machining, and rapid prototyping, providing support for over 500 types of engineering-grade thermoplastic materials.

Service industries: automotive, aerospace, medical equipment, consumer electronics and industrial fields, business covers more than 30 countries and regions around the world.

Core advantages: 99.9% on-time delivery rate, integrated supply chain management, multi-certification compliance (IATF16949, ISO13485), and 24-hour uninterrupted production capacity per week.

Core Advantages of Partnering with China’s Top Plastic Injection Molding Manufacturers

You will benefit from their strong technical barriers, including proficient mastery of precision, intelligent and multi-component plastic injection molding technology. These capabilities can even meet the most stringent industry standards.

Strict quality control is another major advantage. All top enterprises hold certifications such as ISO and CE, and ensure stable and consistent product performance through quality management throughout the entire production process.

Large-scale production helps you balance cost and efficiency. Its large-scale output can reduce unit costs, and streamlining processes ensures rapid and reliable delivery – which is crucial to your project schedule.

They are also skilled at providing customized solutions and offer one-stop services ranging from mold design to finished injection molding. This flexibility can adapt to your unique industry needs.

Furthermore, these leaders practice green manufacturing, using environmentally friendly materials and energy-saving processes to align with your global low-carbon goals

How to Efficiently Engage with Chinese Injection Molding Manufacturers

First, clarify the demands of your industry. If you are engaged in the medical or automotive fields, you should give priority to custom injection molding manufacturers with experience in these niche markets to ensure compatibility.

Explore multiple contact channels: official websites, industry exhibitions, third-party procurement platforms and recommendations from industry associations. All of these are very effective during the initial contact.

When screening partners, particular attention should be paid to on-site factory visits – carefully examining the production area, equipment precision, and quality control processes.

Sample testing and contract negotiation are also key steps in verifying the reliability of partners. Don’t neglect risk mitigation. Clarify the contract terms, intellectual property protection terms, and contingency plans for dealing with delivery delays to ensure the security of your cooperation.

Future Trends Led by China’s Top Plastic Injection Molding Enterprises

Intelligent upgrading will continue to dominate, and Industry 4.0 and artificial intelligence quality inspection will become standard configurations. Driven by the demands of the new energy and automotive industries, lightweight materials will also receive more attention.

The business model is also changing. Top manufacturers are shifting from mere processing to comprehensive solution providers, offering value-added services to enhance supply chain value.

Global expansion is another key trend. These enterprises are accelerating the construction of overseas factories to provide localized services, making international collaboration smoother.

Conclusion

We have compiled a list of 11 outstanding Chinese plastic injection molding manufacturers. All these enterprises possess professional injection molding capabilities, comprehensive one-stop service, and authoritative qualification certifications, which can meet the customized demands of different industries.

Among them, YGTech has over 30 years of experience, with a high-precision production capacity of ± 0.01mm, a global service network, and a full-process quality control system, and is capable of providing all-round support from design to delivery.

If you are seeking a stable and efficient plastic injection molding partner, YG is undoubtedly your best choice. Its flexible production capacity allocation, rapid delivery capabilities, and rich cross-industry service experience can provide a solid guarantee for the upgrade of your supply chain.

Contact us now to start cooperation.