Introduction

Table of Contents

ToggleIn the competitive mobile accessories market, 68% of procurement teams report margin erosion due to unmanaged custom case costs (ABI Research 2023). While the sticker price per unit often dominates negotiations, true cost control requires a systems-level approach. This guide examines seven levers to reduce expenses without compromising quality, drawing on cross-industry best practices and manufacturing engineering principles.

1. Design Phase: Where 74% of Costs Are Locked In

1.1 The DFM Advantage

A MIT Sloan study found that Design for Manufacturing (DFM) optimizations reduce total costs by 18-34% across electronics accessories. Key considerations:

- Tolerance rationalization: Relaxing non-critical dimensions from ±0.05mm to ±0.1mm decreases machining time by 40%

- Texture simplification: Eliminating sub-0.2mm micro-patterns reduces mold polishing costs by $320-$650

- Standardized interfaces: Adopting MagSafe-compatible dimensions (IEC 62368-1) avoids $1.2k-$1.8k in redesign fees

Case Example: A Nordic consumer electronics brand achieved 22% cost reduction by:

- Standardizing charging port cutouts across 12 models

- Using parametric CAD templates for derivative designs

2. Material Selection: Beyond Price Per Kilogram

2.1 Total Cost of Ownership Analysis

| Material | Upfront Cost | Tool Wear Rate | Post-Processing | Defect Rate |

|---|---|---|---|---|

| Virgin PC | $3.20/kg | 1.8% per 10k shots | $0.12/unit | 1.1% |

| 30% GF PC | $3.80/kg | 0.9% per 10k shots | $0.07/unit | 0.4% |

Data source: UL Prospector Materials Database

The glass-filled (GF) option shows 17% lower lifecycle costs despite higher initial price.

2.2 Regulatory Preparedness

With 94% of EU buyers requiring full REACH/SVHC documentation (ECHA 2024):

- Pre-certified material libraries reduce compliance testing costs by $2.7k-$4.5k per SKU

- Dual-source material approval prevents 23% of supply disruptions (McKinsey)

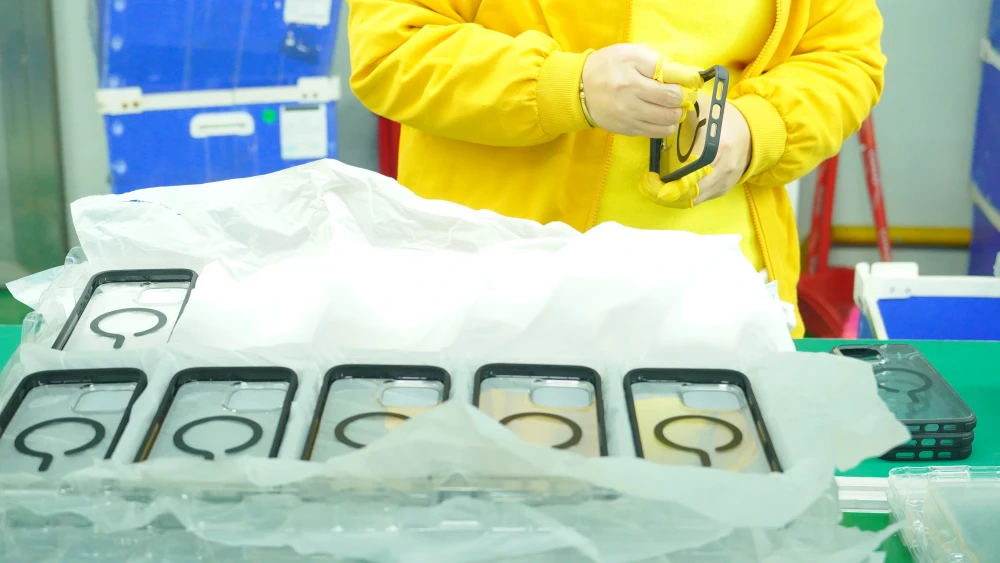

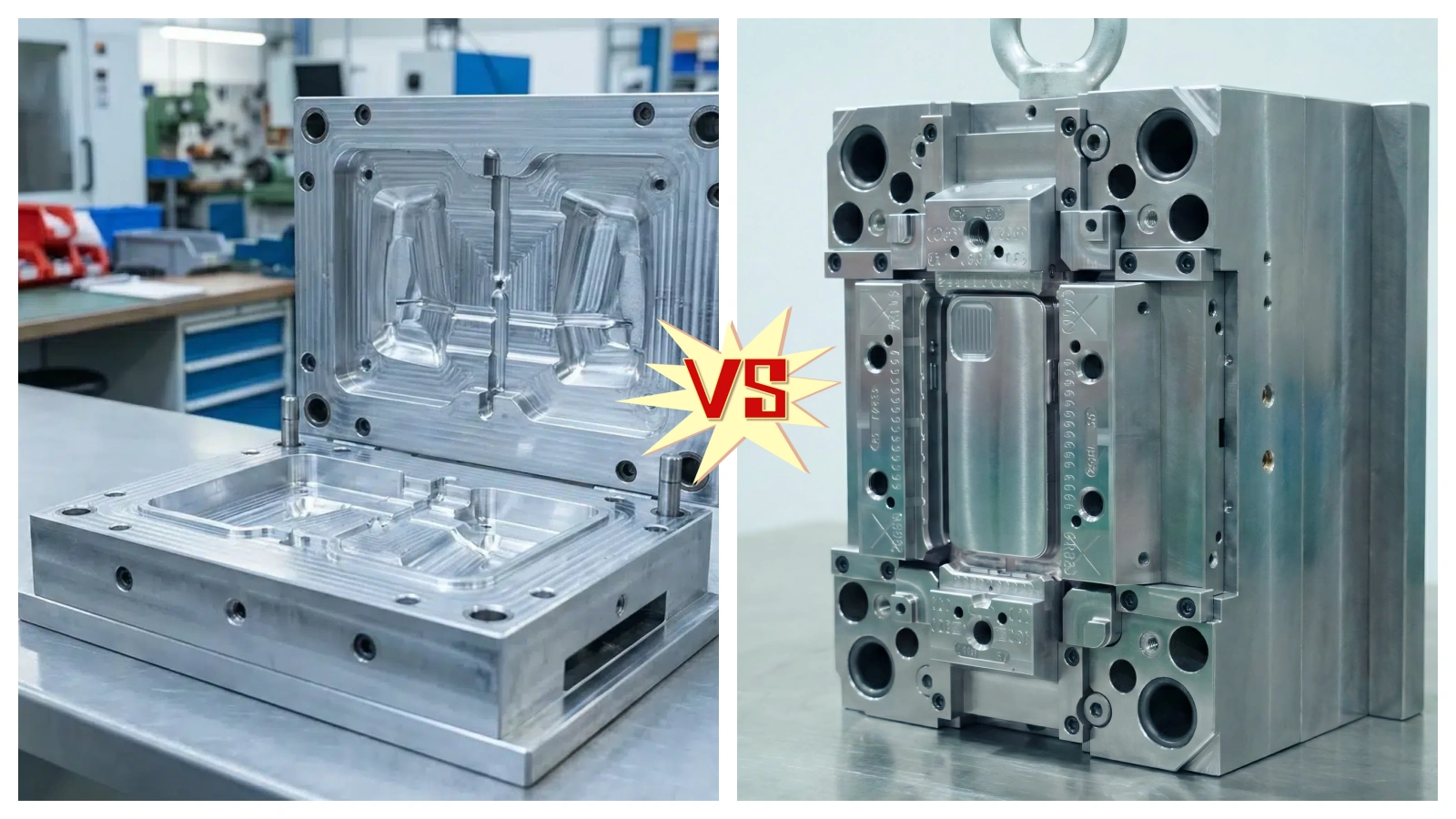

3. Tooling Strategy: Precision vs Flexibility

3.1 Mold Lifecycle Cost Model

Variables:

- Initial tooling: $1,200-$8,500

- Maintenance: $0.003-$0.008 per shot

- Productivity loss from downtime: $18-$42/hour

Optimization Tactics:

- Modular mold bases: 55% faster insert changes for design variants

- Predictive maintenance: IoT-enabled wear sensors reduce unplanned downtime by 67%

- Multi-cavity balancing: 8-cavity molds with <2% weight variation increase yield by 14%

Technical Note: DIN 16742 standards recommend maximum 0.02mm parting line mismatch for Class 101 molds.

4. Supply Chain Orchestration

4.1 Logistics Optimization

- EU Strategy: Utilize bonded warehouses (e.g., Rotterdam) to defer 21% VAT until sale

- US Strategy: Combine LTL shipments with regional fulfillment centers (38% lower last-mile costs)

- Emergency Protocol: Maintain 5-7% buffer stock at strategic hubs for <72hr emergency replenishment

5. Quality Economics

5.1 The Hidden Multiplier Effect

A single defective unit can generate:

- $8.70 in return processing (Reverse Logistics Association)

- $150+ in potential brand damage (J.D. Power)

Preventive Measures:

- Statistical process control (SPC) at 23 checkpoints reduces escapes by 89%

- Automated optical inspection (AOI) with 10μm resolution detects 99.3% of cosmetic flaws

6. Partnership Models

6.1 Collaborative Cost Reduction Framework

Phase 1: Joint Value Analysis Workshop

- Map 136-point cost drivers using VA/VE methodologies

Phase 2: Risk/Reward Sharing Agreement

- Example: Split savings 50/50 from material substitution initiatives

Phase 3: Open Book Cost Monitoring

- Shared dashboards track 18 KPIs from energy use to PPM defect rates

7. Continuous Improvement

7.1 Cost Benchmarking Protocol

- Quarterly material index review (Plastics News pricing)

- Bi-annual tooling audit per NADCA standards

- Annual TCO reassessment with cross-functional team

Conclusion

Sustainable cost reduction requires aligning design intent with manufacturing reality while maintaining rigorous quality standards. By adopting these engineering-led strategies, procurement teams can deliver 19-28% cost improvements – equivalent to $142k annual savings per $1M spend – without resorting to risky corner-cutting.