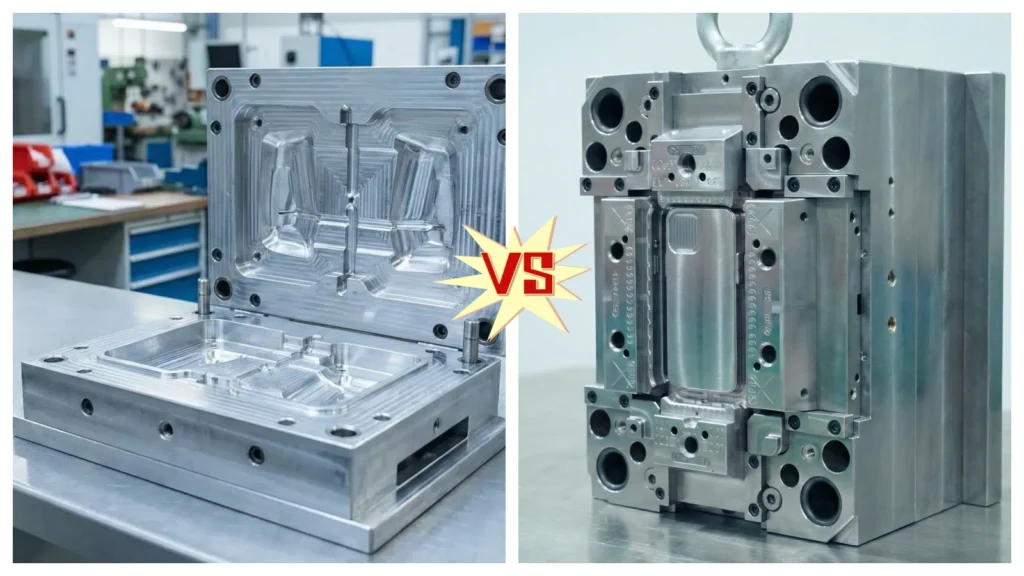

When you are moving a product from a digital design to a physical reality, the biggest decision you will face is how to build your mold. In the manufacturing world of 2026, the choice between Rapid Tooling and Conventional Tooling is more than just a technical detail—it is a business strategy.

Choose the wrong path, and you could find yourself stuck with a massive bill for a mold you don’t need, or worse, waiting months for a tool while your competitors take over the market. This guide will break down everything you need to know about these two methods using clear, simple language. We will look at cost, time, quality, and production volume to help you make the call that protects your bottom line.

The Basics: What are Rapid and Conventional Tooling?

Table of Contents

ToggleBefore we dive into the data, let’s define exactly what we are talking about. While both methods involve injecting plastic into a mold, the “how” and “why” are very different.

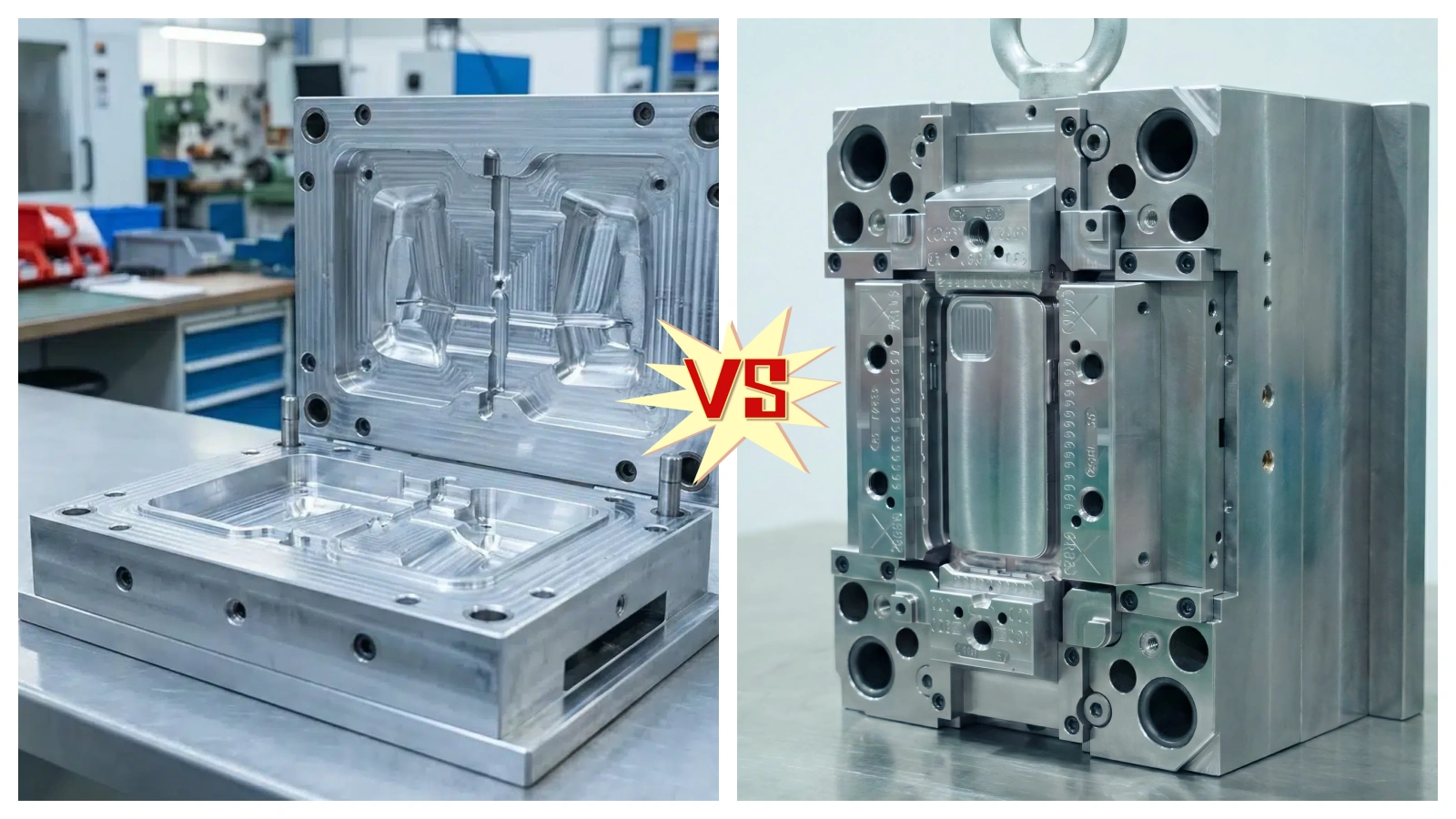

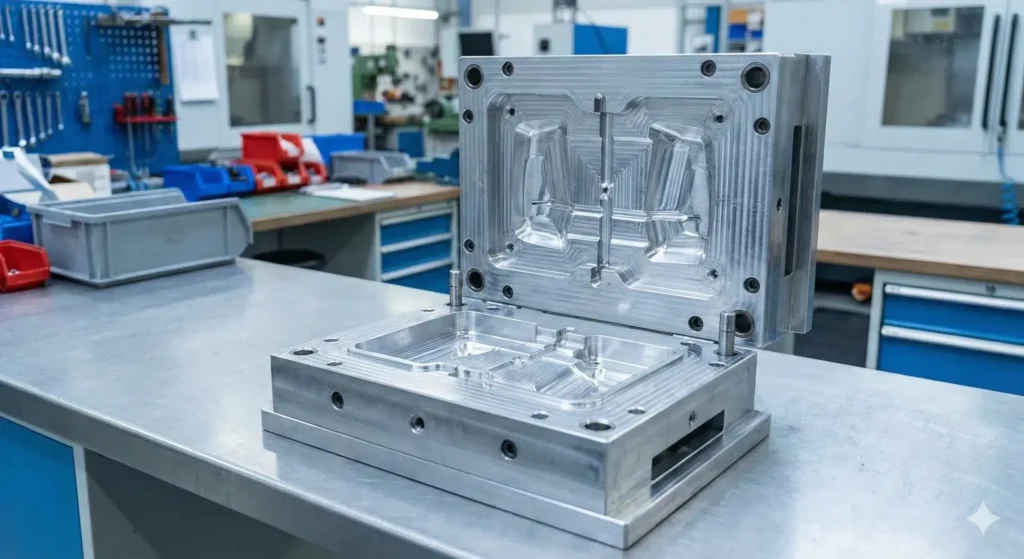

What is Rapid Tooling?

Rapid Tooling is often called “soft tooling” or “bridge tooling.” It is designed to get you from a 3D-printed prototype to a real, sellable product as quickly as possible.

How it is made: These molds are usually made from high-grade aluminum or soft steel using high-speed CNC machining. In some cases, 3D-printed metal inserts are used.

The Goal: Speed and low upfront cost. It is meant for the “middle stage” of a product’s life.

Best for: Production runs between 25 and 5,000 units.

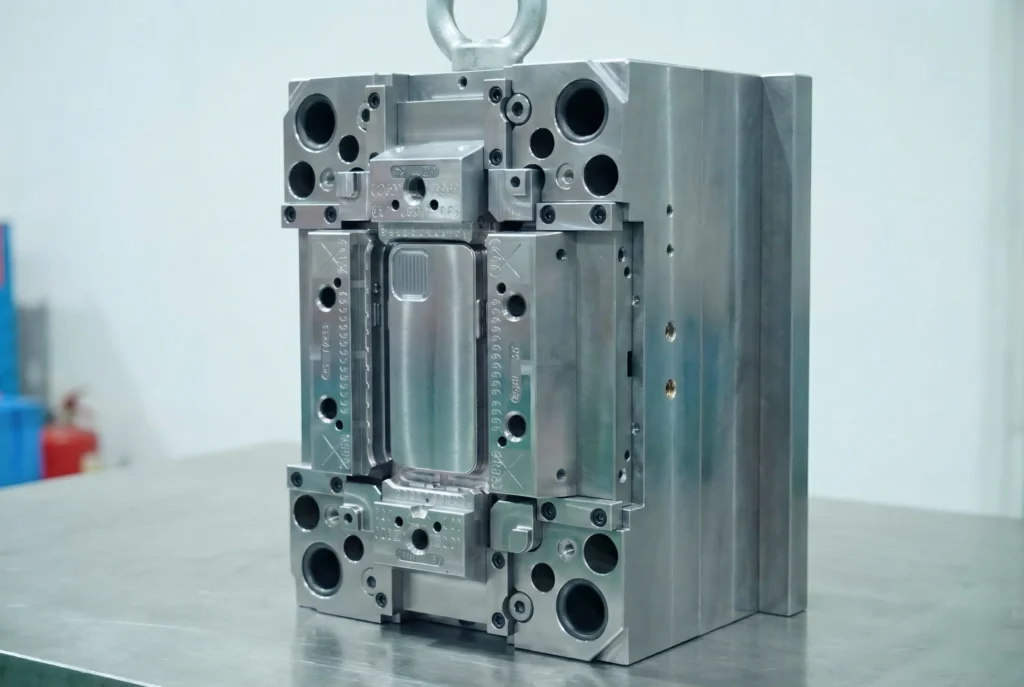

What is Conventional Tooling?

Conventional Tooling is the “hard tooling” used for mass production. This is the gold standard for products that you plan to sell by the hundreds of thousands.

How it is made: These molds are crafted from extremely hard, heat-treated steels like H13 or S136. The process involves multiple stages of precision machining and polishing.

The Goal: Durability and the lowest possible price per part over the long term.

Best for: Production runs from 50,000 to over 1,000,000 units.

Technical Comparison: Material, Precision, and Quality

The material your mold is made of dictates how it performs under the heat and pressure of a 2,000-ton injection molding machine.

Aluminum vs. Steel

When you compare aluminum vs steel tooling for low-volume production, you are looking at two different physical behaviors:

Heat Management: Aluminum is a fantastic conductor of heat. It cools down much faster than steel. This means the plastic inside the mold hardens more quickly, which can actually shorten your “cycle time” (the time it takes to make one part).

Wear and Tear: Steel is incredibly tough. If your plastic resin contains “fillers” like glass fiber or carbon fiber—which act like sandpaper—an aluminum mold will erode very quickly. Steel can handle these abrasive materials for years without losing its shape.

Precision and Surface Appearance

Rapid Tooling: Aluminum is soft, which makes it easier to machine but harder to polish to a “mirror” finish. You can get great functional parts, but if you need a high-gloss, crystal-clear finish, you might struggle with rapid tooling.

Conventional Tooling: Steel can be polished until it is as smooth as a diamond. This allows for high-end textures, specific “leather” grains, or clear transparent parts. It also holds tighter tolerances. If your part needs to fit into another piece with a precision of $\pm0.02mm$, steel is the safer bet.

The Cost of Rapid Tooling and Conventional Tooling

Most people focus on the injection mold’s price, but that is only half the story. You have to look at the Total Cost of Ownership (TCO).

Upfront Cost vs. Unit Price

We need to do a realistic cost comparison between rapid tooling and conventional tooling. Generally, the more you pay for the mold, the less you pay for the parts.

| Comparison | Rapid Tooling (Aluminum) | Conventional Tooling (Steel) |

| Upfront Mold Cost | Low ($3,000 – $10,000) | High ($30,000 – $100,000+) |

| Price Per Part | Higher (e.g., $5.00 each) | Very Low (e.g., $0.50 each) |

| Setup Time | Fast (1 – 3 Weeks) | Slow (10 – 16 Weeks) |

| Mold Life | Short (Under 5,000 shots) | Extremely Long (1 Million+ shots) |

If you are only making 1,000 units, the $5.00 part price of rapid tooling is fine because you saved $40,000 on the mold. However, if you are making 100,000 units, that $4.50 difference in part price adds up to $450,000 in extra costs. In that case, the expensive steel mold pays for itself in just a few months.

The Value of Time

In 2026, the rapid tooling lead time is a major competitive advantage. If you can get your product to customers 3 months before your competitor, that “early bird” revenue often outweighs the higher cost per part. If your product generates $10,000 in profit every month, waiting 12 weeks for a steel mold is effectively a $30,000 loss in opportunity.

The Middle Way: How to Use Bridge Tooling

You don’t always have to pick just one. Many successful companies use a “hybrid” business strategy called Bridge Tooling.

The Bridge Tooling Timeline:

Phase 1: Build a rapid aluminum mold in 2 weeks. Start selling immediately to your first 1,000 customers.

Phase 2: Use the revenue from those sales to fund the expensive conventional steel mold.

Phase 3: While the steel mold is being built (which takes 3 months), you gather feedback from your first customers. If they say, “I wish the handle were slightly bigger,” you can change the design of the steel mold before it is finished.

Phase 4: When the steel mold arrives, your market is already “warmed up,” and you can switch to high-volume production with a design you know people love.

Decision Factors: Four Questions to Ask Yourself

If you are still on the fence, run your project through these four filters.

Question 1: Is the design finalized?

If there is any chance you will change a screw hole, a button, or the thickness of a wall next month, choose rapid tooling. Modifying aluminum is cheap and fast. Modifying hardened steel is a nightmare that can cost thousands of dollars and weeks of delay.

Question 2: What material are you using?

Standard plastics like ABS, Polypropylene (PP), and Polycarbonate (PC) work great in both. But if you are using “High-Performance” plastics or glass-filled resins, the tooling life of an aluminum mold will drop significantly. For “tough” plastics, steel is usually necessary.

Question 3: How many do you actually need?

Under 5,000 units: Rapid Tooling. It keeps your cash free for marketing.

5,000 to 20,000 units: This is the “grey zone.” You might want a “semi-hardened” steel tool or a high-end aluminum tool.

Over 50,000 units: Conventional Tooling. Anything else is a waste of money in the long run.

Question 4: How fast do you need to be?

If you have a window of opportunity—like a holiday season or a trade show—and you need parts in 3 weeks, conventional tooling is physically impossible. You must go with a rapid path.

Case Studies: How Others Decided

Case Study A: The Tech Startup

A small company developed a new smart home sensor. They were not sure if people would buy it, and they only had $15,000 in the bank.

Decision: Rapid Tooling.

Result: They got 1,000 units in 3 weeks. They realized the battery door was too hard to open. Because they used a rapid tool, they “fixed” the mold for $400 and 2 days of work. If they had bought a steel mold, they would have been stuck with a bad design or a massive repair bill.

Case Study B: The Mature Manufacturer

A company making classic, high-demand phone cases needed to produce a model that has been a top-seller for three years.

Decision: Conventional Tooling.

Result: They spent $5,000 on a single-cavity steel tool. Because the tool can run 24/7 without breaking, its cost per case dropped to $0.25. They made their money back in the first four months and have been printing profit ever since.

The Final Checklist

To make your decision today, check the boxes that apply to you:

I should choose Rapid Tooling if:

[ ] I need parts in less than 4 weeks.

[ ] My total order is under 5,000 pieces.

[ ] I might need to change the design soon.

[ ] I want to save my cash for other things.

I should choose Conventional Tooling if:

[ ] I need 50,000+ parts.

[ ] The design is 100% finished and will not change.

[ ] I need the lowest possible cost per part.

[ ] I am using very abrasive or high-heat plastics.

FAQ

Q: Is the quality of rapid-tooled parts lower?

A: Not necessarily. In 2026, rapid tooling can produce high-quality, “production-grade” parts. The main difference is how many parts you can make before the quality starts to drop. For the first few thousand parts, the quality is virtually identical to conventional molding.

Q: Does an aluminum mold really wear out?

A: Yes. Aluminum is a “soft” metal. Every time the mold opens and closes, and every time plastic is injected at high pressure, the metal wears down slightly. Usually, after 5,000 to 10,000 shots, the edges lose their sharpness, and you might see “flash” (extra plastic) on your parts.

Q: Can I use my rapid tool CAD files for a steel mold later?

A: Yes, the 3D design of the part stays the same. However, a professional mold designer will need to adjust the mold layout. For example, a steel mold might have 8 “cavities” (making 8 parts at once), while a rapid tool might only have 1 or 2.

Q: Which one is more sustainable?

A: For small volumes, Rapid Tooling is better because it takes much less energy to create the mold. For massive volumes, Conventional Tooling is more efficient because it produces less scrap and uses less energy per part produced.

Conclusion

There is no “perfect” tool—there is only the tool that fits your current situation. Rapid Tooling is about speed, flexibility, and saving your cash. It is the best way to start. Conventional Tooling is about scale, margin, and long-term stability. It is the best way to grow.

By understanding these differences, you can navigate the manufacturing world with confidence and ensure your project is a success.

Are you ready to see the numbers for your specific project? The best way to decide is with real data. Upload your 3D files today for a free DFM (Design for Manufacturing) analysis. Our engineers will look at your design and tell you exactly which tooling path will save you the most money.