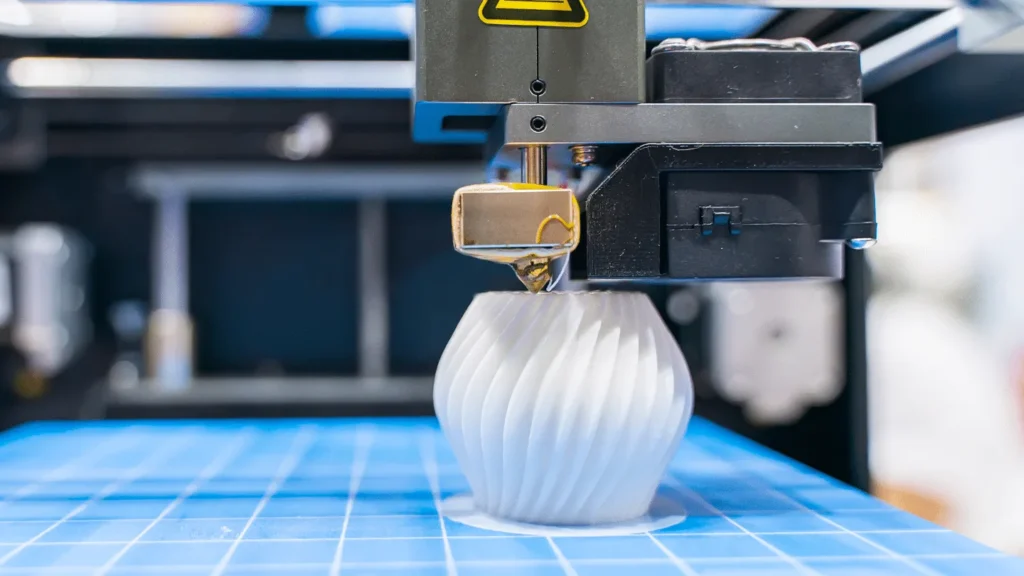

What Is Rapid Prototyping?

Table of Contents

ToggleThese methods work with materials like ABS, PC, and PP, fitting your short-cycle R&D demands for rapid prototyping.

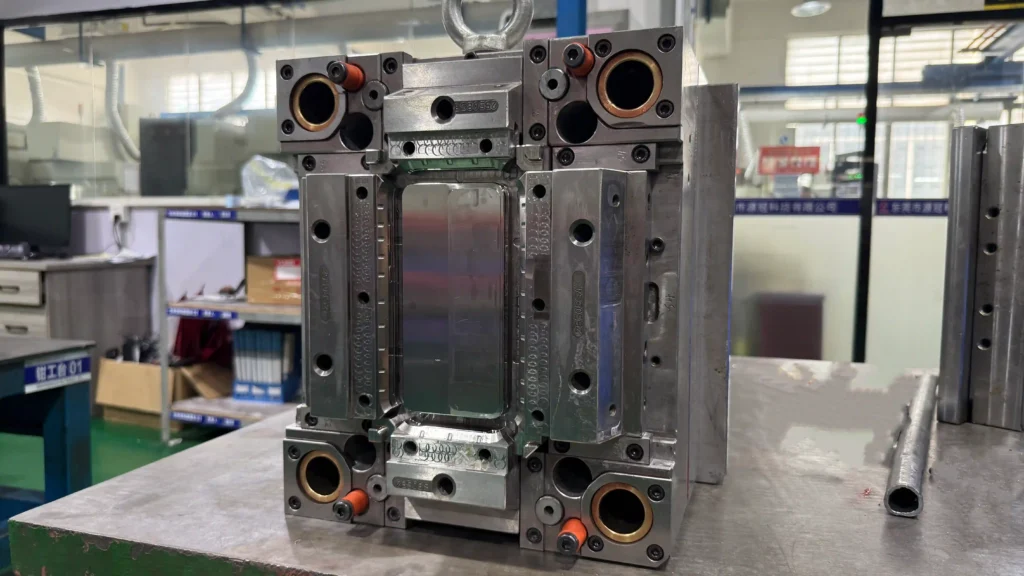

What Is Rapid Tooling?

Rapid tooling bridges prototyping and mass production for your small-batch plastic orders.

It focuses on low-cost, fast mold making to deliver production-like parts via rapid tooling.

Silicone rubber tooling and aluminum soft tooling are popular for plastic products.

They support injection molding and casting, matching mass-production processes.

This rapid tooling method suits your needs for market testing or small-order fulfillment (50-5000 units).

Key Differences Between Rapid Prototyping and Rapid Tooling

Comparison Dimension | Rapid Prototyping | Rapid Tooling |

|---|---|---|

Purpose | Verifies designs, functions, and appearances of plastic parts | Enables small-batch production and mass-production process simulation |

Lead Time | Hours to 3 days, perfect for urgent plastic samples | 3-10 days (mold + production) for consistent plastic parts |

Batch Size | 1-50 samples for plastic product concept testing | 50-5000 units for plastic product market trials |

Cost | No mold fees, but higher unit costs for plastic parts | Low-cost mold fees, unit costs drop with increased batch size |

Material Compatibility | Supports limited resins for plastic samples | Works with production-grade plastics (ABS, PP, PE) for final products |

When to Use Each Method

Opt for Rapid Prototyping If…

You’re in the early R&D phase, validating plastic product designs via rapid prototyping.

You need samples for mechanical or assembly tests without strict production standards.

You’re preparing for trade shows and want to control initial costs.

Opt for Rapid Tooling If…

You have small-batch orders and want low-cost, rapid tooling for small batches instead of mass-production molds.

You need to simulate mass-production processes to fix injection molding defects like flow marks.

You’re launching a trial run to test market demand before full-scale production.

How to Choose Between Rapid Prototyping and Rapid Tooling?

First, clarify your core goal: design validation or order fulfillment?

Rapid prototyping fits the former, while rapid tooling serves the latter.

Consider batch size and timeline: <50 units (1 week) = rapid prototyping.

50-5000 units (1-2 weeks) = rapid tooling for plastic products.

Prioritize material and precision: production-grade plastics need rapid tooling.

Sample-only tests can rely on rapid prototyping to save time and costs.

YG: Your Trusted Partner for Rapid Tooling

YG offers professional and rapid tooling solutions and collaborates with reliable suppliers for rapid prototyping.

We specialize in mold manufacturing and related injection molding processes. Familiar with international standards (RoHS, REACH), we ensure that your parts meet market demands.

Our one-stop solution covers the entire process from rapid prototyping to rapid mold manufacturing and small-batch delivery.

Stuck between rapid prototyping and rapid mold? Contact the YG team today.

We will customize plans based on your batch size, schedule, and precision requirements.