Have you ever received a rapid prototype offer that made you hesitate? “Why is this small component so expensive? ” Or, can I really afford to test multiple designs?” If you are a buyer preparing for mass production, especially in fields such as consumer electronics, rapid prototyping is a necessary condition for verifying ideas. But how much does rapid prototyping cost?? This is usually a mystery.

Today, we will conduct a detailed analysis of the factors driving the rapid prototyping cost, how different rapid prototyping methods are economically superimposed, and how to cut costs without sacrificing quality. In addition, we will show you how to work with a one-stop supplier like YG to turn prototype chaos into a smooth process.

Why Rapid Prototyping Costs are Important to You

Rapid prototype is not just a “just have it” thing – the benefits of rapid prototyping to prevent costly mistakes from occurring in mass production. Imagine investing in an injection molding for phone cases, only to find that the design is imperfect or the material feels very cheap. The rapid prototype tooling solved this problem.

But a poor prototype design can quickly deplete your budget. The real question is not “How much will it cost?” Rather, it’s “How can I make the most of every penny I spend?”

The Core Cost Components of Rapid Prototyping

1. Material cost: It’s not just the materials themselves

The plastic, resin, or metal you choose can have a huge impact, but so can waste. Common materials and their price ranges

- Plastic (ABS, TPU, PC): 10-50 per kilogram

- Resin (for SLA printing): 30-80 per kilogram

- Metals (aluminium, stainless steel): 50-200 pieces per kilogram

Waste adds another layer: the waste rate of most methods is 10-30%.

2. Process Costs: Equipment + Consumables

3. Labor & Expertise

A rapid prototype is not just about printing or cutting – it also requires post-processing (grinding, coloring) and design adjustments. Skilled technicians charge $20 to $50 per hour. Complex parts (such as phone cases with built-in card slots) may take 2 to 3 hours to complete.

4. Quality Checks: Avoiding “Close Enough” Prototypes

Rapid Prototyping Methods: Which One Fits Your Budget?

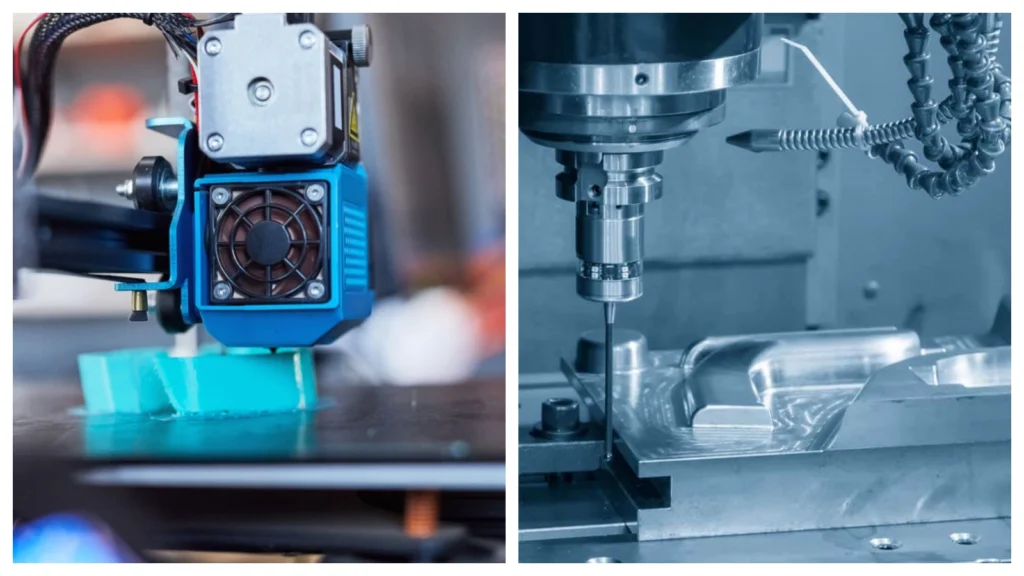

1. 3D Printing: Best for Quick, Low-Cost Iterations

- Purpose: High-precision appearance prototypes (e.g., a transparent PC phone case with logo texture).

- Cost:15-40 per hour /30-100 per prototype.

- Pros: Ultra-fine details – it seems almost ready for production.

- Purpose: High-precision appearance prototypes (e.g., a transparent PC phone case with logo texture).

- Cost:15-40 per hour / 30-100 per prototype.

- Pros: Ultra-fine details—looks almost production-ready.

- Cons: Resin is brittle (not good for drop tests).

- Purpose: Functional prototypes (e.g., the impact-resistant core of a rugged phone case).

- Cost:20-50 per hour / 40-150 per prototype.

- Pros: Material costs are 2x higher than FDM.

- Cons: Material costs are 2x higher than FDM.

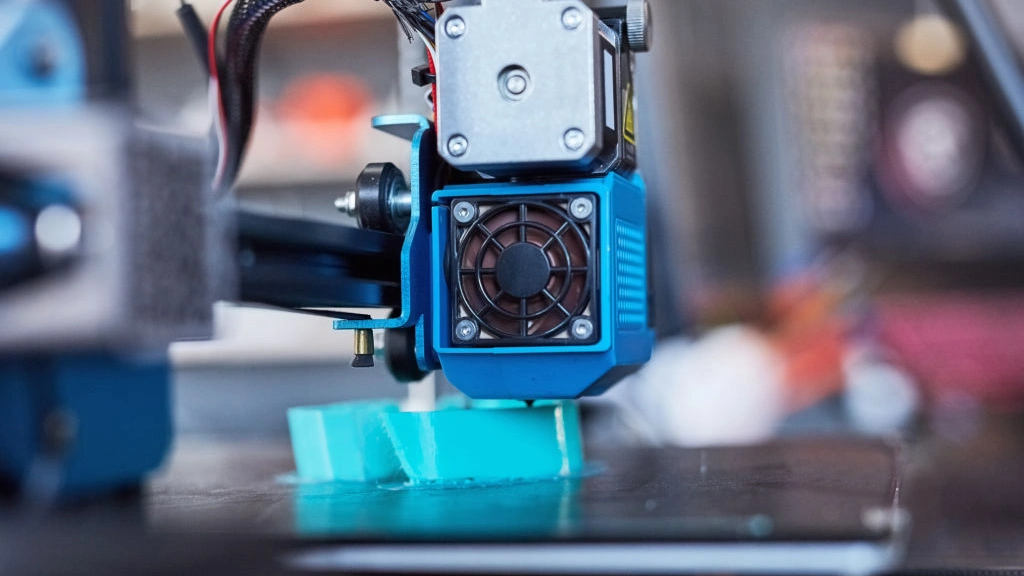

2. CNC rapid prototyping: Best for Durable, Production-Like Parts

- Purpose: Metal prototypes or high-strength plastics (e.g., an aluminum phone case frame for durability testing).

- Cost:30-80 per hour / 50-200 per prototype.

- Pros: Parts are strong enough for real-world use.

- Cons: Slow for intricate designs—expect 1–2 days per part.

3. Vacuum Casting: Best for Small-Batch Samples

- Purpose: 10–50 prototypes (e.g., silicone phone case samples for focus groups).

- Cost:100-300 for the mold / 10-30 per cast part.

- Pros: Low per-unit cost—great if you need multiple copies.

- Cons: Molds only last 20–50 uses (not for large batches).

4 Key Variables That Make Your Prototype More (or Less) Expensive

1. Quantity: More = Cheaper (Eventually)

- 1-5 pieces: High unit cost (for example, 1 SLA prototype =50, the total cost of 5 is 180)

- 10 to 50 pieces: Vacuum casting can reduce the unit cost by 30 to 50%.

- Pro tip: If you need multiple iterations, please process them in batches! Suppliers prefer bulk discounts.

2. Design Complexity: Simple = Affordable

3. Precision & Finish

- Tolerance: ±0.1mm is the standard. ±0.05 millimeters increases by 25-40% (if your final product uses injection molding, this is redundant and such precision cannot be achieved in any case).

- Surface treatment: Polishing (5-15 / prototype) is very cheap, but UV coating (15-40/ prototype) will increase the cost even more

4. Rush Orders: Time = Money

Common Ways to Cut Rapid Prototyping Cost

1. Integrate Your Supply Chain

2. Align Prototypes with Mass Production

3. Design for Manufacturability (DFM) Early

4. Choose the Right Material

Choose Your Rapid Prototyping Service

3. Your One-Stop Service Partner

Your journey with us is like this:

- Share your phone case ideas (sketches, specifications – anything you have).

- We coordinate prototypes (and revisions, if necessary).

- “Approved prototype?” We’ll just open the mold directly.

- We handle injection molding and delivery.

3 Tips for Balancing Rapid Prototyping Cost & Quality

- Clarify your goal first: Write down, “Do I need this prototype to test suitability, functionality, or appearance?” This avoids overspending.

- Avoid rush orders: Plan 1–2 weeks for rapid prototype development (even if you think you’re in a hurry).

- Choose a one-stop partner: The time you save on coordination is often more important than the small price difference of independent rapid prototyping companies.

Conclusion

Rapid prototyping price doesn’t have to be a puzzle, and you don’t have to manage it alone. As your Chinese phone case manufacturer, YG streamlines the chaos of rapid prototype machining, mold making, and mass production into a smooth and stress-free process.

Whether you are testing your first phone case design or mass production, we will provide you with a clear quotation, manage the details, and ensure that your rapid prototype tooling is consistent with the final product.

Contact us today to get a personalized, fast rapid prototyping quote and free DFM analysis. Let’s turn your idea into a product – no trouble.