In the competitive smartphone accessories sector, YG, a leading B2B phone case manufacturer, has upgraded its production infrastructure with cutting-edge equipment to enhance precision, speed, and flexibility. This article highlights the key technologies—Japan’s Makino slow wire EDM/mirror spark machines and a 20-unit fleet of Sumitomo-Haitian high-speed injection molders—and their value for industrial partners.

I. Precision Mold Making: Redefining Detail and Speed

Table of Contents

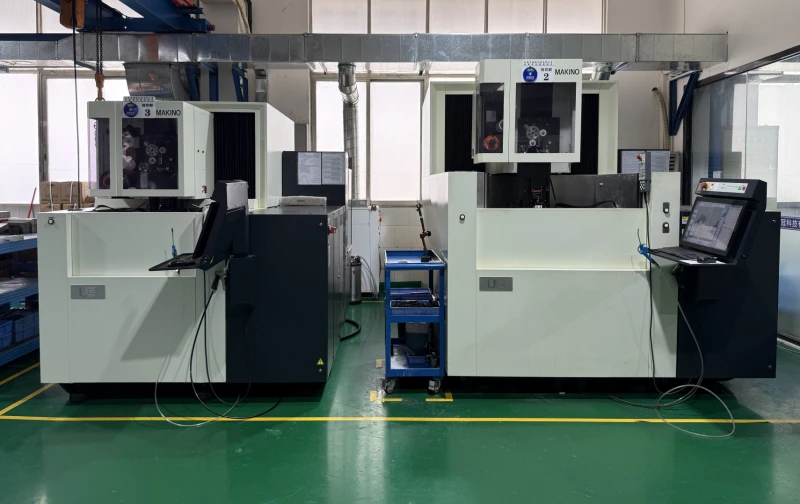

Toggle1. Makino Slow Wire EDM: Micron-Level Accuracy

The Makino EDGE3i Sinker EDM machine achieves ±0.01mm precision, critical for ultra-thin (0.1mm) or complex curved designs. Its unidirectional wire feed reduces electrode wear, extending mold life by 200% compared to traditional mid-wire machines. This ensures consistent quality in mass production, ideal for clients requiring long-term mold reliability.

2. Mirror Spark Machining: Elimination of Post-Processing

The Makino U3 Wire EDM uses powder-mixed discharges to create Ra≤0.1μm mirror surfaces on molds, eliminating manual polishing. This cuts mold lead times by 30% and doubles mold lifespan, enabling seamless production of premium finishes like metallic textures or transparent gradients.

II. High-Speed Injection Molding: Speed Meets Smart Control

1. Sumitomo Direct-Drive Machines: Rapid Cycle Times

Five Sumitomo SE-EV-S series injection molding, with 800mm/s injection speed and FFC technology, reduce thin-wall case cycles by 15%. Perfect for time-sensitive promotions, they help brands launch products faster without compromising quality.

III. Core Benefits for B2B Clients

1. Quality & Reliability

Combined technology boosts yield to 98.5% (vs. industry 92%), reducing rework and delivery risks—critical for brands with strict quality standards.

2. Scalability & Flexibility

Monthly capacity of 5M units handles both large orders and small trials. 4-hour model switchovers align with frequent smartphone launches, letting clients adapt quickly to market trends.

3. Sustainability & Cost

Energy-efficient designs cut carbon footprint by 22% and production costs by 18%, meeting EU regulations and improving margins.

IV. Industry Impact: Trends in Precision & Agility

As consumer demand shifts to personalized, multi-material cases, YG’s upgrades reflect two key trends:

- Precision: Enabling intricate designs through micron-level mold accuracy

- Flexibility: Supporting small batches and rapid model changes, a must for today’s fast-paced market

The Technology Collaboration Lab further enhances partnerships, offering mold flow analysis and real-time production monitoring for collaborative innovation.

Conclusion

YG’s equipment modernization transcends hardware upgrades, representing a leap in manufacturing philosophy—prioritizing technical transparency, adaptability, and shared value. For brands, this means accessing a future-ready supply chain that balances speed, quality, and sustainability. In an industry where design complexity and market responsiveness define success, these advancements position YG as a strategic partner for tomorrow’s challenges.