Welcome to YG Phone Case Factory

As an experienced phone case manufacturer, YG provides one-stop customized services from phone case design to production and final delivery. We specialize in the manufacture of mobile phone cases made of plastic, silicone, environmentally friendly materials and many other materials. We are committed to providing you with phone case products that meet the industry’s high standards, helping your business to achieve greater profits and brand growth.

Custom Phone Case Manufacturer - YG

As a leading phone case factory, we deliver original designs tailored for businesses,

enhancing brand identity and providing a competitive edge in the market.

We Provide ODM Services

We can provide you with a one-stop turnkey service from mobile phone case design to final delivery, helping you save time and cost while ensuring product quality and innovation.

YG Phone Case Manufacturing Process

As a china phone cases manufacturer, YG provides one-stop solutions that cover every aspect of your project.

From innovative design and prototyping to mass production and quality assurance, our services will make your business more profitable.

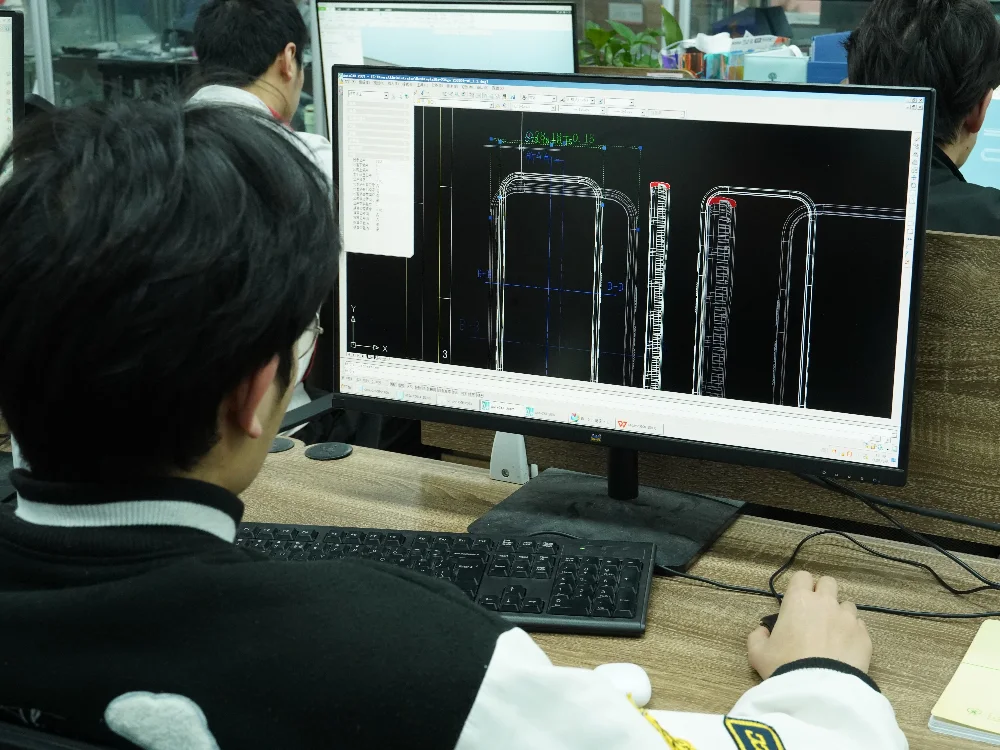

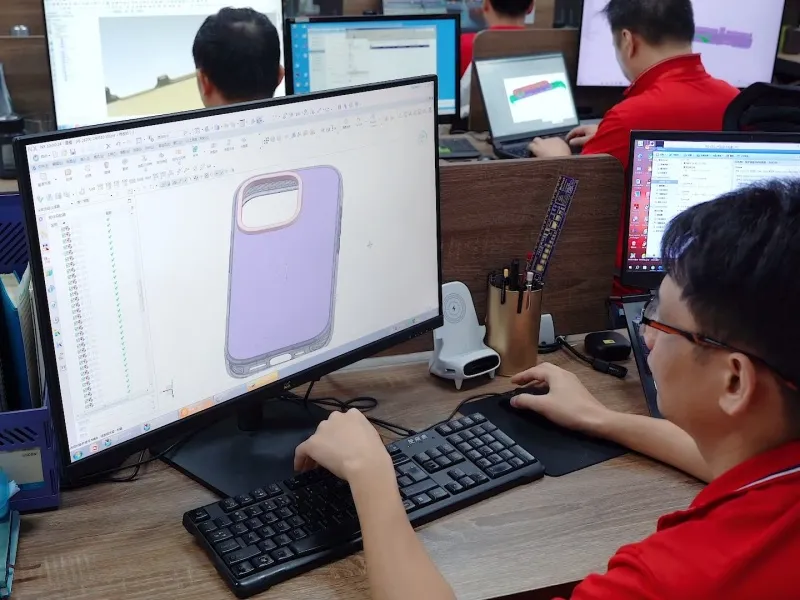

Design the Case

Our team designs the case based on your demands. The design fee is USD 500, which could be returned after you kick off tooling.

Material Selection

During the design phase, we help select suitable materials, taking into account your preferences and environmental concerns.

Prototyping

We make a prototype to verify the structure and appearance. The lead time is about 7 days and cost is about USD 400.

Refinement & Testing

We refine and re-test the prototype if necessary, ensuring it meets all design specifications.

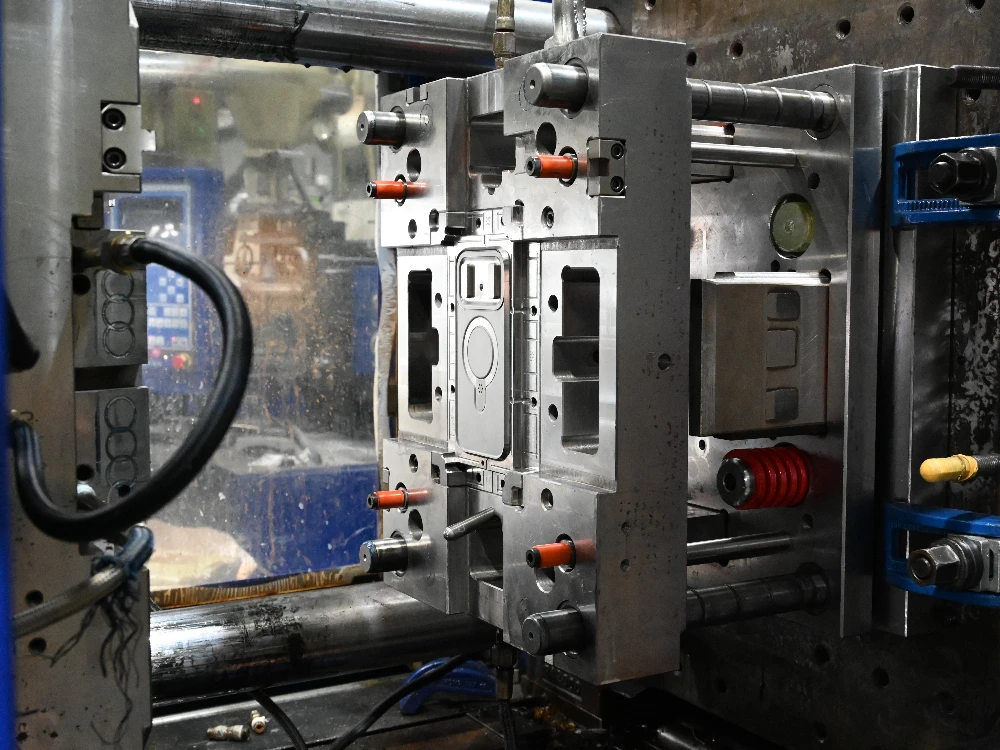

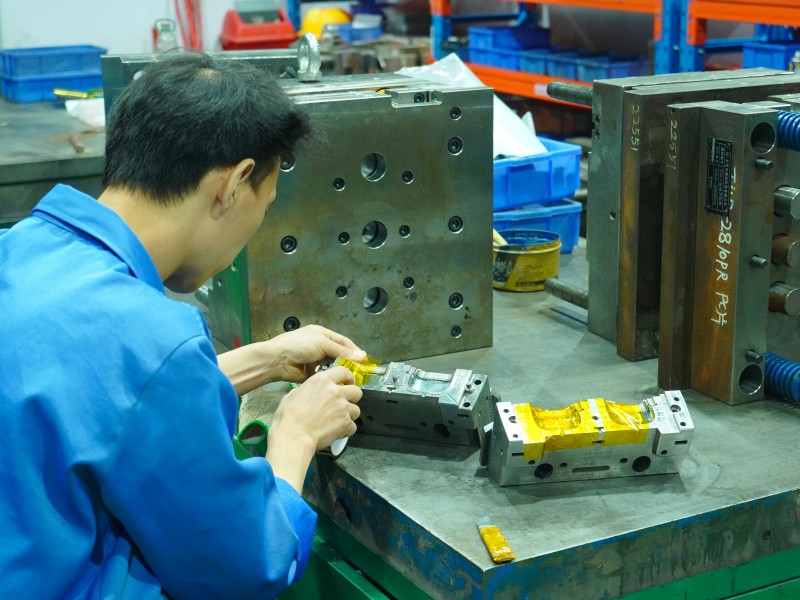

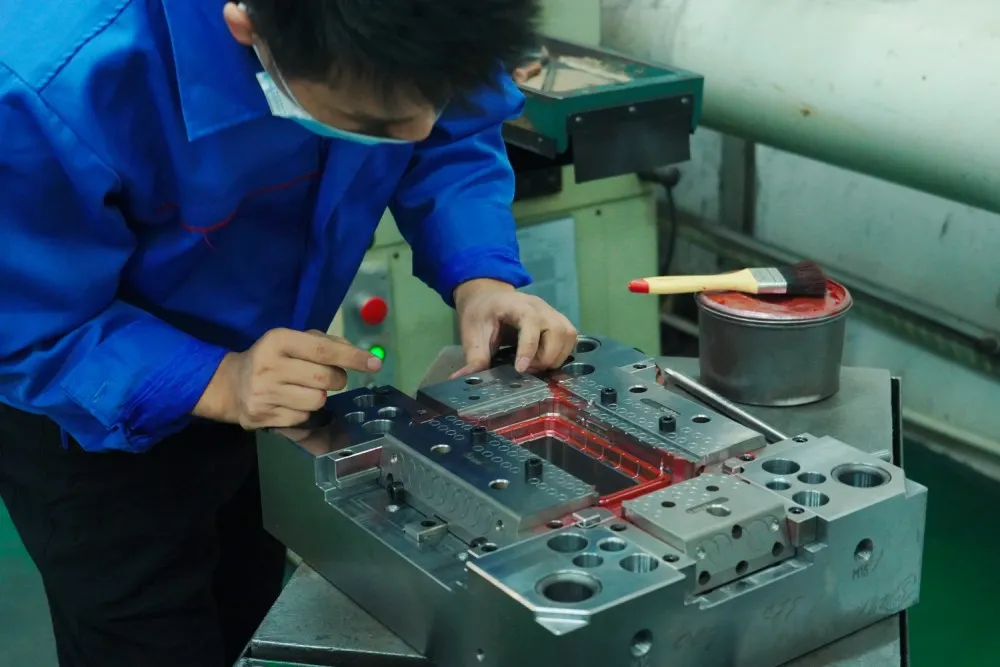

Mold Making

Once the design is finalized, we kick off the tooling, which takes about 35 days.

Packaging Solutions

We work on packaging design, create samples, and seek your confirmation to ensure the packaging meets your standards.

Golden Sample

We require your sign-off on the golden sample before proceeding to mass production.

Injection Molding

The lead time for mass production is approximately 15 days.

Quality Assurance

Before delivery, we perform a final inspection to ensure all products meet the agreed-upon standards and specifications.

Logistics & Shipping

We coordinate logistics and shipping arrangements to ensure timely and secure delivery of your products.

Everything is Customizable

Materials

YG provides a wide selection of materials, from eco-friendly to premium finishes, ensuring durability and visual appeal.

Design

The YG team of 30+ designers collaborates with you, offering industrial, mechanical, and electronic design services.

Features

Customize phone cases with features like shock absorption, wireless charging, water resistance, and antimicrobial protection.

Logo

Select from methods like screen printing, digital printing, or embossing to perfectly match your branding needs.

Injection Molds

We use MUD technology for precise custom injection molding, backed by 40 engineers with over a decade of experience.

Packaging

YG excels in packaging design, enhancing product protection and the unboxing experience to reinforce your brand.

Ready To Elevate Your Brand?

Partner with YG, your trusted custom cell phone case manufacturer, for innovative solutions. Contact us today to discuss how we can bring your vision to life with our customized phone case offerings.

Manufacturing Capabilities

YG is a leading phone case factory equipped with precise CNC machines and flexible injection molding equipment, supported by our experienced team of engineers. Our goal is to help you enhance your product line, accelerate time-to-market, and support your business growth.

Innovating today for the solutions of tomorrow.

- Over 120 injection molding machines, producing 300,000 phone cases and assembling 30,000 sets daily.

- More than 80 mold-making engineers, creating 150 molds monthly.

- A team of 100+ product developers and 40+ engineers, each with over 10 years of experience.

- Streamlined logistics and delivery systems ensure timely and reliable product shipment to meet customer demands.

Unmatched capacity for your growing needs.

- Utilizing over-molding and IM-3D-E technology for multi-material bonding and electronic integration, including wireless charging and NFC.

- Employing heat transfer printing and IMD for vibrant, durable designs.

- Using nano coating and ultrasonic welding for waterproof, anti-fingerprint, and antibacterial properties, ensuring strength and precision.

- Holding 77 R&D patents, offering innovative solutions.

Innovating today for the solutions of tomorrow.

- Adhering to ISO standards with a comprehensive quality management system.

- 53 quality managers oversee IQC, IPQC, FQC, and OQC, ensuring top standards.

- Equipped with advanced testing equipment to maintain defect rates well below industry averages.

- Issuing detailed quality reports and retaining samples for traceability.

Efficiency that saves you more.

- Implementing JIT production to minimize inventory and storage costs.

- Automated lines and advanced technologies like IM-3D-E and MUD reduce labor and time.

- Long-term supplier relationships and bulk purchasing lower material costs.

- Flexible production adapts to customer needs, reducing unnecessary expenses.

Recent Cases of Phone Cases

Grateful for Their Trust

Related Products