Imagine this: Your phone slips out of your hand again. But you won’t feel panicked; instead, you will feel calm. Why? Because your phone case uses overmolding technology, it is a game-changing process that combines hard protection with soft cushioning. If you want to know why some phone cases can survive at a height of 10 feet while others break and crack, keep reading, and you will soon discover the scientific principle behind it.

What Is Overmolding?

Table of Contents

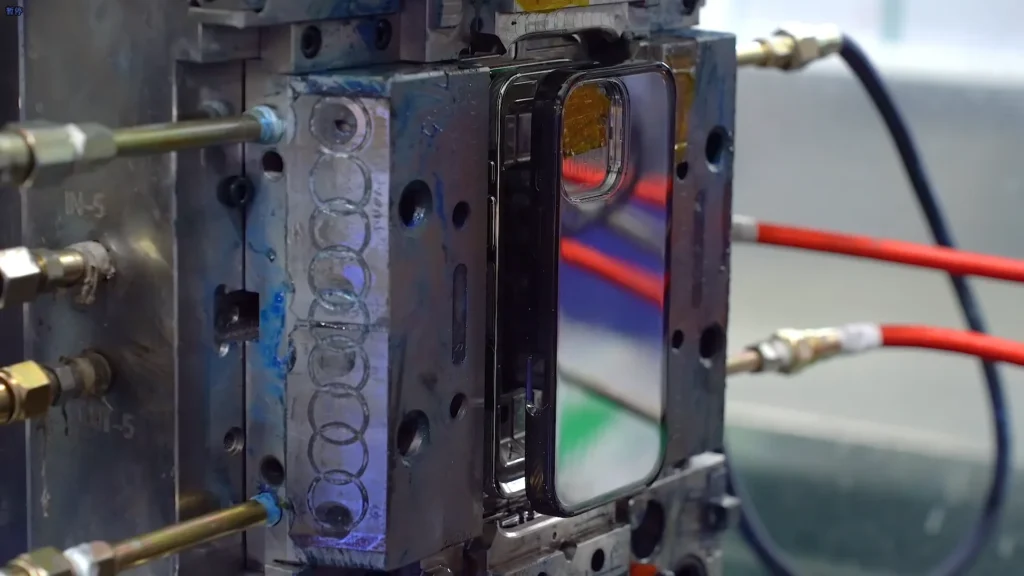

ToggleInjection molding is the main method for rapid mass production of mobile phone cases. It involves several different techniques, including insert molding, Two-shot molding, and overmolding. Today, let’s first learn about the overmolding technology.

Simply put, overmolding bonds two materials into one unbreakable unit. You can think of it this way:

Unlike cheap adhesive boxes, this overmolding process creates adhesion at the molecular level. Materials are fused through chemical and mechanical means:

- Anchor points: Micro-cavities in the base lock with soft material.

- Thermal bonding: Controlled heat (80°–110°C) merges material layers.

For a phone case manufacturer, this means no weak seams. For you? Military-grade protection without bulk.

Common Overmolding Materials

Material selection is an important step before the manufacturing of a phone case, and it is the foundation for realizing the functions of the phone case. In the overmolding process, the selection of materials is more demanding because the overmolding material and the base material must be compatible to enable the two materials to form chemical and physical bonds during the manufacturing process. Their effective bonding helps ensure the durability of the phone case. Incompatible materials may cause deformation or malfunction.

Therefore, it is a wise choice to clarify the compatibility of the overmolding materials during the design stage of the mobile phone case. Of course, cooperating with a professional mobile phone case factory, such as YG, will provide you with the most professional material combination recommendations. Through mold injection molding, our scientifically verified materials include:

| Base Material | Overmold Material | Superpower Combo |

|---|---|---|

| Polycarbonate (PC) | Thermoplastic Polyurethane (TPU) | Shatter-proof rigidity + 90% shock absorption |

| Recycled ABS | Bio-based TPE | 100% ocean plastic core + plant-based grip |

| Translucent PMMA | Liquid Silicone Rubber (LSR) | Glass-like clarity + baby-skin softness |

Silicone overmolding deserves special attention. Unlike cheaper rubbers, medical-grade LSR:

- Anti-yellowing (even under ultraviolet rays

- Passes skin-contact toxicity tests (ISO 10993)

- Maintains grip when wet

Ever noticed “greasy” residues on cheap cases? That’s plasticizer leakage—eliminated in true silicone overmolding.

The Application of Overmolding in Mobile Phone Cases

How does overmolding transform daily protection? Let’s analyze three cases that you can trust:

Case Study 1: Military-grade anti-drop Protective phone cases

- Problem: Ordinary silicone or plastic shells can only provide slight drop protection from about 3 feet. Adding airbags or honeycomb structure designs can raise it to a height of 5 feet. However, high-risk outdoor activities require military-grade protection.

- Overmolding solution:

- 2mm PC base

- Strategic TPU overmolding at corners (2mm impact zones)

- Result: Passed MIL-STD-810G tests. Your mobile phone is still alive.

Case Study 2: Biodegradable Plant-based Eco-friendly Phone Cases

- Problem: Traditional plastic phone cases cannot be degraded or have a long degradation cycle. The mechanical strength of biomaterials is insufficient and the tensile strength is weak.

- Innovation:

Base material: Straw fiber /PLLA composite material

Overmolding material: Castor oil-based TPU

- Your benefits: the cost is only 15% higher than that of a regular PC+TPU shell, and the carbon footprint is reduced by 42%.

Case Study 3: Magnetic Phone Case

- Challenge: Magnets weaken through thick layers.

- Engineering:

- Laser-cut magnetic array embedded in the PC base

- 0.25mm overmolded silicone preserves field strength

- Outcome: Perfect alignment, no charging lag.

The advantages of overmolding

1. It can achieve outstanding appearance effects and design freedom:

- Complex textures and patterns: The backplate can be independently made with fine surface textures (such as embossed brand logos) and high-gloss mirror effects.

- Two-color/multi-color effect: Backplates of different colors or materials can be perfectly covered with transparent or colored soft or hard rubber, such as TPU/TPE/PU.

- Embedding special materials: The backplane can be made of special materials, such as metal sheets or carbon fiber composite materials.

2. Enhance functionality and protection: For instance, TPU wrapping the PC back plate can provide excellent impact resistance for the phone case.

3. Enhance production yield: For complex mobile phone cases, break down the intricate structure into two relatively simple molding processes to reduce the difficulty of single-pass molding.

4. Flexible production: The backsheet and cladding molding steps can be carried out at different times and locations, increasing the flexibility of production scheduling. Moreover, the initial production cost is lower than that of two-color injection molding.

The Disadvantages of Overmolding

1. The production cost is higher than that of single-color injection molding:

- Two injection molding machines are needed, and the costs of equipment purchase, maintenance, and energy consumption have increased.

- High total mold cost: Two sets of molds need to be designed and manufactured, which is more costly than single-pass molding molds.

2. Reduced production efficiency: Each product needs to go through two complete injection molding cycles, and the overall production efficiency is lower than that of a single injection molding.

3. Process complexity and yield challenges

- The challenge of precise positioning: Positioning deviation can lead to uneven product thickness, glue overflow (burrs), glue shortage, and even mold damage.

- Temperature control sensitivity: During the second injection molding step, if the insert temperature is too low, it will lead to poor bonding between the coating material and the insert (reduced adhesion and increased risk of delamination).

- Material compatibility issue: The plastic materials used in the first and second steps must have good chemical and thermal compatibility to ensure a strong molecular-level bond (rather than mechanical interlocking).

- Stress concentration and warping risk: When two different materials are combined, it is more likely to cause overall warping deformation of the finished product or internal stress concentration in the bonding area, affecting long-term durability.

The overmolding technology is mainly applied to high-end mobile phone cases that have high requirements for appearance effect, special functions, or protective performance, and whose target market can afford high costs. Phone case brands must carefully weigh whether the unique value they bring can cover the risks associated with their costs and complexity.

Your Overmolding Checklist (Before Choosing a Partner)

Not all overmolding services are equal. Ask suppliers:

✓ “Do you simulate melt flow dynamics?” (Avoid trial-and-error factories)

✓ “Can I see material certs?” (Demand FDA/ROHS documents)

✓ “What’s your part-to-part tolerance?” (±0.05mm ensures fit perfection)

Remember: True overmolding injection molding merges science and artistry. Your brand deserves both.

Elevate your phone cases with YG’s precision overmolding expertise—combining unbreakable protection with sleek design. Let’s create your next bestseller in record time.

.webp)