What company in China makes AirPods cases that blend innovation with speed? Meet YG – your expert custom AirPods cases manufacturer with over 30 years of expertise. We helped an American tech brand conquer holiday sales with high-quality AirPod cases. Here’s how we did it.

1. The Challenge: High Demand for AirPods Transparent Case

Table of Contents

ToggleAn American electronics startup needs custom AirPod cases for Christmas sales. Their demands are very strict:

- Visual uniqueness: The clear shell showcases the design of AirPods, along with a distinctive brand pattern.

- Durability: The AirPod case material must be resistant to scratches and yellowing (common defects of TPU).

- Time to market: 3 months from design to listing.

- Complies: EU REACH and Amazon packaging standards.

“Most case suppliers quoted 16 weeks. Christmas would be over by then.“ – Client Product Manager

2. YG’s Solution: Offering the Best AirPods Cases

As a top AirPod case manufacturer in China, we strive for excellence in materials, craftsmanship, and production:

A.High-quality TPU material

We have a powerful material supply chain network. The TPU materials we select comply with environmental protection and safety standards such as RoHS, REACH, and FDA.

- Special UV stabilizers and antioxidants are added to prevent yellowing.

- Shock-absorption foam layers for drop protection.

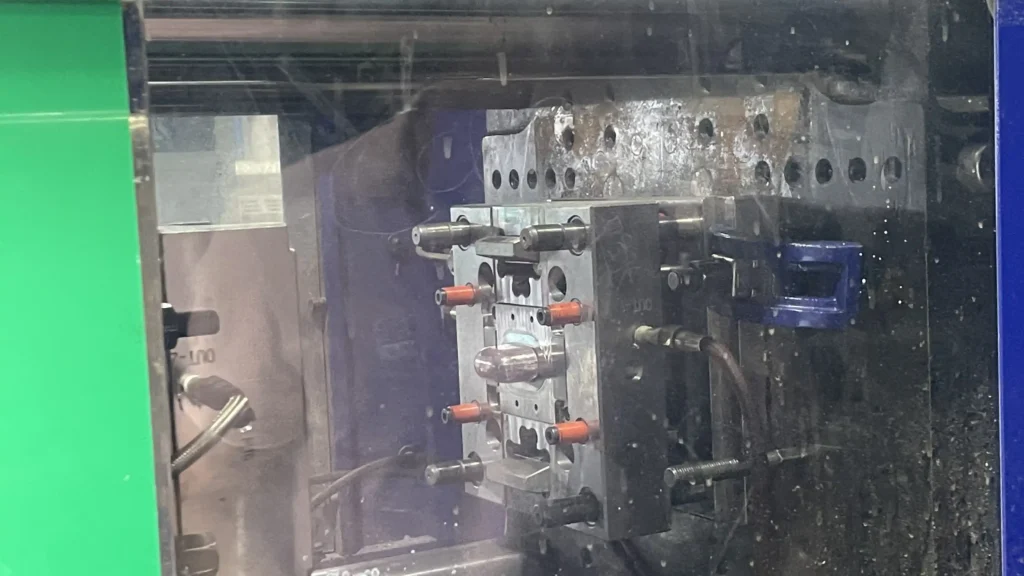

B. IML Technology

Our IML process ensures perfect patterns:

Artwork → Digital printing →IML coating → Injection molding → Hard coating

AirPods cases produced through the IML process can offer a three-dimensional and clear pattern effect and will never peel off. Unlike the UV printing process that directly attaches patterns to the product surface, the IML process first attaches the patterns to two PET films and then places them in an injection molding machine for injection molding.

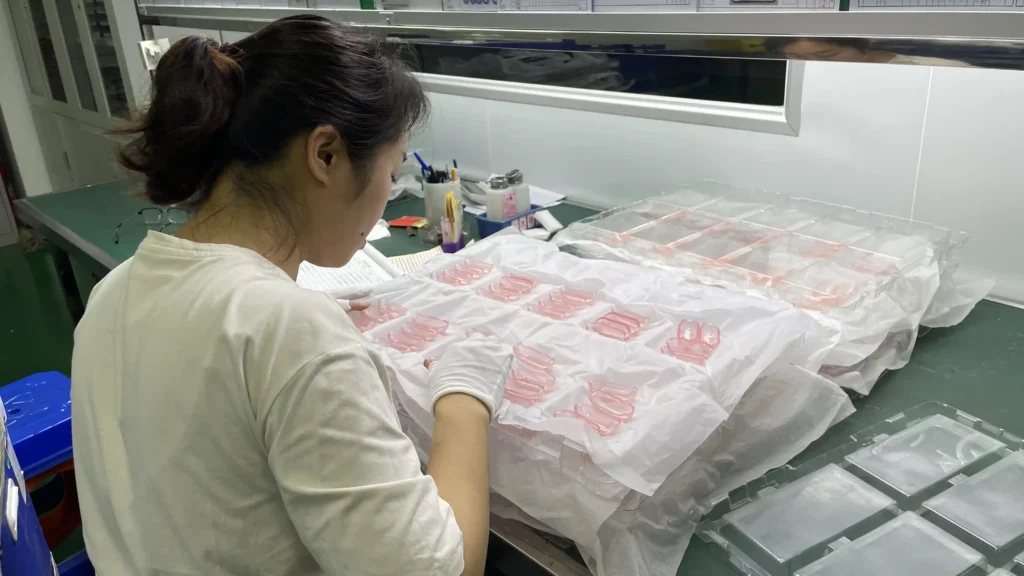

C. Lightning-Fast Production

YG’s professional engineering team and complete production line equipment ensure the rapid delivery of AirPod cases:

- 18 CNC Machines + 17 EDM machines

- 40+ mold engineers

- 150+ sets of molds/month

- 130+ injection molding machines

- 300k cases/day

3. Results: Exceeding Expectations

Within 11 weeks (35% faster than industry average), we delivered:

| Metric | Outcome | Client Benefit |

|---|---|---|

| Speed to Market | Production completed in 11 weeks | Captured 35% Christmas market share |

| Quality | 0% defect rate on 5,000 Amazon units | Saved $12,000+ in returns |

| Eco-Compliance | 30% GRS-certified recycled TPU | Met strict EU EPR regulations |

4. Why YG is Your Trusted AirPod Case Manufacturer

- top-notch production techniques: With over 80 R&D patents, including the application of IML technology and transparent TPU materials.

- strict quality management:

- Quality managers are responsible for supervising IQC, IPQC, FQC, and OQC to ensure the highest standards.

- Equipped with advanced detection devices, the defect rate is maintained at a level far below the industry average.

- It has certifications such as ISO 9001:2015, ISO 14001, SMETA, BSCI, and ISCC PLUS

5. Your Path to Best AirPod Cases

As a leading custom AirPod case manufacturer in China, YG combines:

- Material science (premium AirPod case materials)

- Cutting-edge IML tech

- Blazing 11-week production

“YG delivered the best AirPods case we’ve seen – on time, flawless, and eco-friendly.”

Ready to create your signature AirPod case covers?

.webp)