Introduction

Table of Contents

ToggleWhen searching for a phone case supplier, it is essential to strike a balance between quality, cost, and delivery time for bulk orders. Have you ever wondered which production process – injection molding or 3D printing – best suits your business goals? Or how to weigh 3D printing vs injection molding pros and cons for your specific needs?

As a trusted phone case manufacturer and the best injection molding company, we break down key differences to help you make the wisest decision for your next order. Let’s get started.

How Are Phone Cases Manufactured

Before we compare injection molding vs 3D printing, let’s clarify how each method translates into phone case production – no technical terms, just the facts that buyers need.

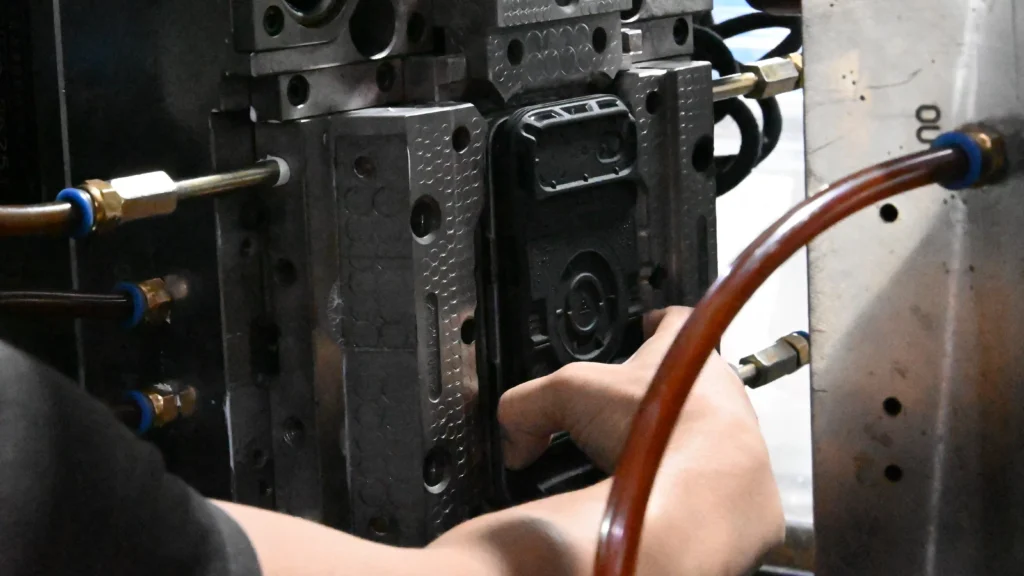

Injection molding: Mass production standards

Injection molding is the preferred process for phone case manufacturers to serve bulk orders, especially for those phone case brands seeking high-precision injection molding.

The following is the decomposition process: Molten plastic materials(such as TPU, PC, silicone, or ABS – the preferred choice for all durable, market-oriented phone cases) is injected into a custom mold under high pressure. Once cooled, the mold is opened, and a uniform finished phone case is ready.

For you, this means scalability. Even low-volume injection molding (for smaller batch orders) offers reliability, but the true value lies in large quantities. As a leading injection molding company, we rely on this process to produce thousands of identical, high-quality phone cases, perfectly meeting the demands of mass production.

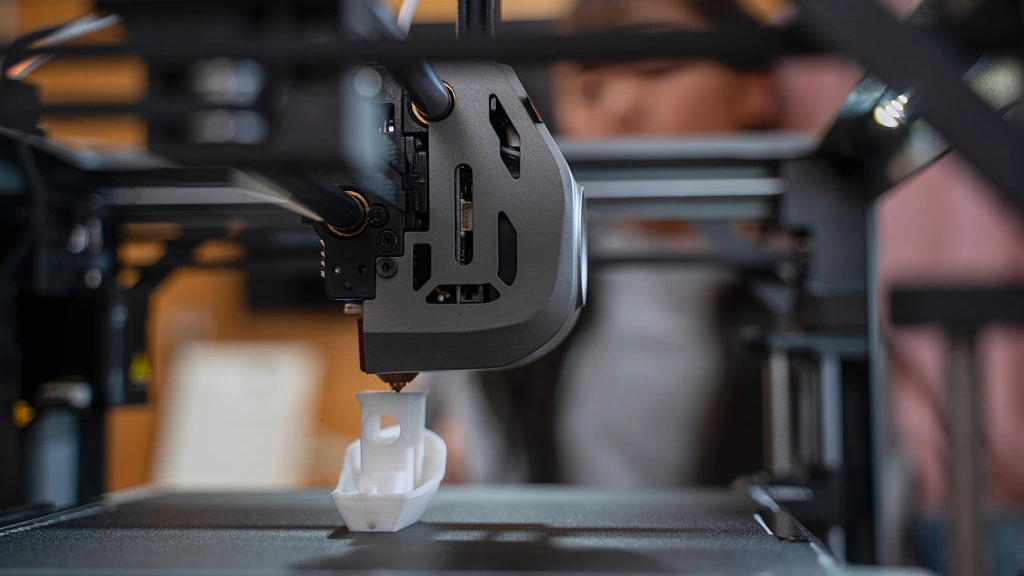

3D Printing: Customized & Small-Batch Solution

3D printing (also known as additive manufacturing) uses materials such as resin, PLA, or PETG to manufacture phone cases layer by layer. Unlike injection molding, it doesn’t require molds – you just need to upload a digital design and the printer will turn it into reality. You can even test the design by using a prototype of a 3D print injection mold before full-scale production.

This process is about flexibility. If you are looking for limited edition designs, personalized phone cases, or small-batch prototypes, 3D printing can offer speed and customization. But what will the situation be like when you need over 5,000 units in the European and American markets? Let’s compare injection molding and 3D printing in key indicators.

Injection Molding vs 3D Printing: 6 Critical Factors for Bulk Orders

1. Cost Efficiency

- Injection molding: The initial mold cost may be higher, but once production begins, the unit cost will drop significantly. Even compared with 3D printing, this is the case for small-batch injection molding. For orders of over 5,000 units, this is by far the most cost-effective option. As an injection molding manufacturer, we often see that when buyers choose this method for large orders, they can save 30-50% of the unit cost.

- 3D printing: The absence of mold costs means lower initial investment, but the comparison between the costs of 3D printing and injection molding becomes a disadvantage, as the unit cost remains high even in small batches. The speed of printing only one phone case at a time is relatively slow, so expanding the scale to over 1,000 units will become extremely expensive.

2. Production Speed & Lead Times

- Injection Molding: Injection mold tooling takes 3 to 5 weeks (depending on the complexity of the design, especially high-precision injection molding), but once the mold is ready, we can produce over 10,000 phone cases every day. Even small-batch injection molding offers faster delivery times than 3D printing, with batches exceeding 1,000 pieces, which is crucial when meeting retail deadlines.

- 3D Printing: Prototypes or small batches (100 or fewer) can be ready within a few days, but scaling up is slow. Printing 1,000 phone cases may take several weeks, which makes it impossible for large orders to be completed before tight deadlines.

3. Quality & Durability

- Injection Molding: This process – especially high-precision injection molding – creates seamless, consistent mobile phone cases with smooth surfaces and strong structural integrity. Materials like TPU and PC offer superior 3D printing vs injection molding strength, providing the shock resistance and durability that high-end consumers demand.

- 3D Printing: The printed cases usually has visible layer lines (unless you pay expensive post-processing fees), and lacks the strength of 3D printing and injection molding. Most 3D printing materials cannot match the durability of TPU or pc.

4. Material Options

- Injection Molding: Injection molding offers a wider range of material options: soft TPU thin cases, hard PC heavy-duty protection, silicone grips, eco-friendly phone cases, and advanced designs with hybrid materials. You can add matte finishes, UV protection, or water resistance functions, all of which are incomparable to 3D printing.

- 3D Printing: The material options are limited, mainly resin (fragile) or PLA (not impact-resistant). It is almost impossible to replicate the popular textures or protection features that sell well in the target market.

5. Design Flexibility

- Injection Molding: It is most suitable for standardized designs, but high-precision injection molding can handle complex patterns and advanced mold designs (although it increases costs). The ideal mass-market phone case, the best-selling category.

- 3D Printing: Perfect complex, unique designs – limited editions, letter combinations, or experimental shapes. Before mass production, you can even 3D print injection mold prototypes to test the design. But this flexibility has vanished in scale.

6. Sustainability

- Injection Molding: Most materials (TPU, PC, ABS) are recyclable, generating the least amount of waste during the production process, which is crucial for meeting sustainable development standards. We also offer biodegradable options for environmentally conscious buyers.

- 3D Printing: Many materials (such as resin) are non-recyclable, and this process generates even more waste. If your brand prioritizes sustainability, this could be a red flag.

Which Process Should You Choose?

Choose Injection Molding If:

- You ordered over 1,000 pieces.

- You need outstanding injection molding strength and consistent quality.

- You want low unit costs.

You’re selling standardized mass-market phone cases.

You need a detailed design for high-precision injection molding.

Choose 3D Printing If:

- You ordered fewer than 1,000 units (limited edition, prototype, or custom order).

- Design uniqueness and customization are more important than cost or speed.

- Before mass production, you want to 3D print the injection mold prototype to test the design.

YG: Your Trusted Injection Molding Manufacturer

- High Precision Injection Molding Expertise: We customize molds based on your design, and the standard design turnaround time is 3 to 5 weeks.

- Flexible Volume Options: We handle small-batch injection molding orders ranging from over 1,000 units to over 100,000 units, with short delivery times (2-3 weeks after mold approval).

- Material Versatility:TPU, PC, silicone, ABS, or eco-friendly materials can be selected – all comply with European and American safety standards (RoHS, CE, FCC) certification.

- Hybrid Prototyping Solutions: Need to test the design? We offer 3D printing prototypes (including 3D printing injection mold services), and then expand to injection molding.

- End-to-End Support: From design optimization to packaging and transportation, we handle every step to ensure that your phone case arrives on time and is ready for sale.

FAQ

Conclusion

Now that you have mastered injection molding and 3D printing and their advantages and disadvantages, it’s time to take action. If you order over 1,000 units, injection molding (especially high-precision injection molding) is a clear choice in terms of cost, quality, and speed. If you need small-batch customization or prototypes, 3D printing is an option.

As your most reliable injection molding company, we are here to assist you at every step – whether you need custom molds, 3D printed prototypes, or batch injection molding production. Let’s turn your vision into reality

Contact us today to get a free quote. We can’t wait to cooperate with you!

.webp)