1.Introduction

Table of Contents

ToggleDemand for durable, stylish, and affordable phone cases is soaring in today’s world. Injection molding is the undisputed champion for the mass production of these essential accessories, offering unparalleled accuracy, scalability, and cost effectiveness.

This comprehensive guide delves deeply into how injection molding phone cases work, covering everything from prototyping to quality control. Whether you are a phone case designer, manufacturer, or entrepreneur, this guide will provide you with actionable insights.

2. About Injection Molding

Before delving into the details of phone cases, let’s introduce the basics of injection molding, which is crucial for understanding why it dominates plastic manufacturing.

2.1 What is Injection Molding?

Injection molding is a manufacturing technology that melts plastic particles and injects them into a metal mold cavity under high pressure. Once cooled and solidified, the mold will open to extrude the finished product. The core components include:

- Hopper: Feeds plastic pellets into the machine.

- Barrel and screw: Melts and homogenizes the plastic.

- Heater bands: Maintain optimal melting temperatures.

- Mold: A custom-designed tool that shapes the part.

- Clamping unit: Holds the mold shut during injection.

- Ejector system: Removes the cooled part.

This automated cycle makes injection molding an ideal choice for high-volume products such as phone cases, ensuring rapid and consistent output with minimal waste.

2.2 Advantages and Disadvantages of Injection Molding

Understanding the advantages and limitations of plastic injection molding can help you plan your phone case project

Advantages of injection molding :

- Large-scale cost-effectiveness: Large-scale production (for example, over 10,000 units) will significantly reduce the cost of each component.

- Precision and repeatability: Producing the same components with strict tolerances is crucial for the fit of your phone case.

- Speed: The cycle time for each part is as low as 15-30 seconds, allowing for mass production. This helps you quickly capture the market.

- Material diversity: Suitable for various thermoplastics, allowing for customization of impact resistance, clarity, or flexibility, effectively meeting your customized requirements for phone case materials.

- Complex geometry: Create thin-walled, textured, and other features that cannot be achieved by other methods to meet the complex needs of your cell phone case.

Injection molding defects :

- High initial investment: Mold tooling costs can be substantial (10,000–10,000–100,000+), making it less viable for small batches.

- Design constraints: Requires uniform wall thickness and draft angles for easy ejection.

- Lead time: Mold design and fabrication can take weeks to months, delaying production starts.

- Economies of scale: Not cost-effective for prototypes or low volumes (under 1,000 units).

2.3 Why Injection Molding is Ideal for Phone Cases

Due to its unique market demand, injection molding is highly suitable for the production of mobile phone cases:

- Volume handling: Efficiently meet your massive consumer demands, with an annual output of up to one million cases.

- Precision engineering: Achieving the comfortable fit required by modern smartphones, precisely cutting buttons, cameras, and ports.

- Aesthetic and functional versatility: enables designs ranging from ultra-thin, flexible TPU cases to rigid, textured PC cases – all with consistent quality.

- Durability and consistency: Offers excellent impact protection and uniform performance.

- Cost-effectiveness: Reduce the unit cost of mass production and enhance the brand’s profitability.

In short, a phone case injection molding factory can perfectly transform your design concept into a reliable and fast market-ready mobile cover through injection molding, making it the first choice for phone case manufacturing.

3. The Phone Case Injection Molding Process Steps

Manufacturing mobile phone cases by injection molding involves meticulous steps from prototyping to quality checks. Here is a detailed breakdown to ensure the perfect execution of your plastic phone case manufacturing.

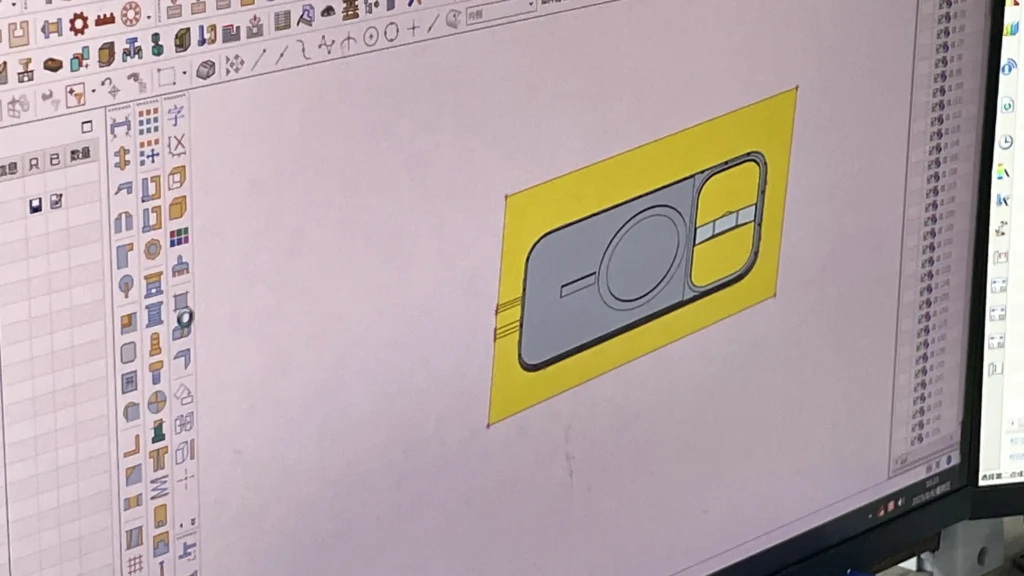

3.1 Prototype Design

Before investing in expensive molds, verify your design with prototypes. Create physical models using methods such as 3D printing or CNC machining:

- Test fit and functionality: Ensure that the housing is perfectly aligned with the phone’s size and allows for easy access to the ports.

- Aesthetic evaluation: Check the color, texture, and ergonomics in actual use.

- Rapid iteration: Improve the design based on feedback to avoid costly mold modifications in the later stage. Prototype design reduces the risks in the production of phone cases and effectively saves your time and resources.

3.2 Mold Design & Mold Making

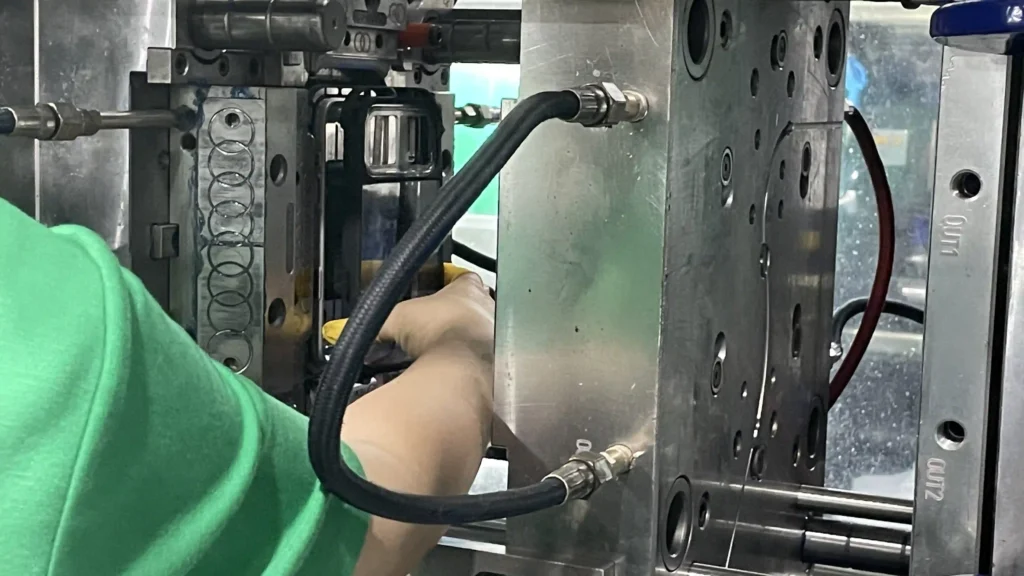

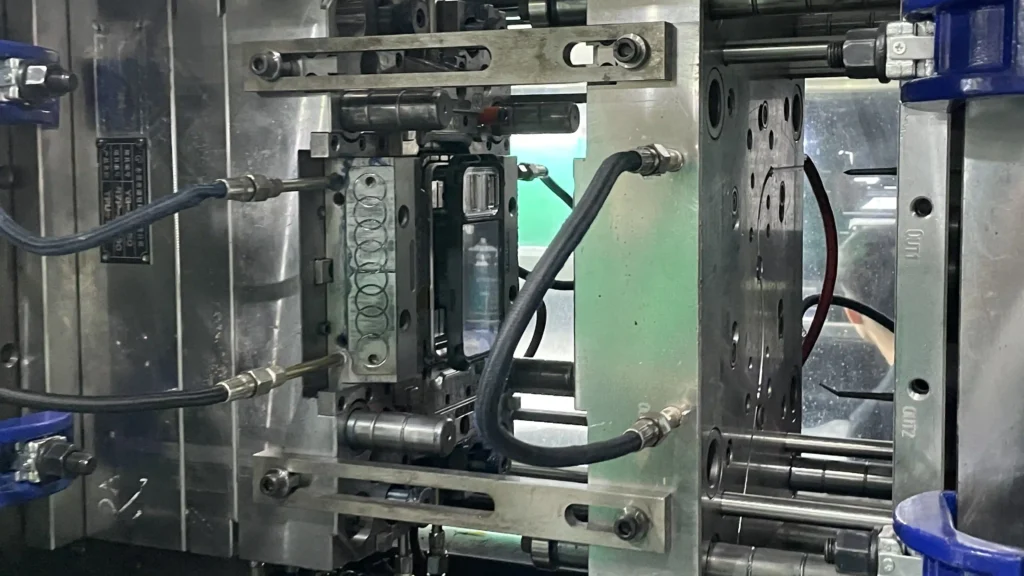

Molds are the cornerstone of injection molding for mobile phone cases, determining quality, cycle time, and lifespan. The design of mobile phone case molds requires high precision due to their thin walls and complex details:

Key design considerations:

- Parting line: The position that minimizes visible seams and flashes (for example, along the edge of the housing).

- Draft angles: Incorporate 1–2° angles for smooth ejection from deep cavities.

- Wall thickness: Keep it uniform (usually 1-2mm) to prevent defects such as subsidence marks.

- Undercuts: For complex functions (such as button covers), use slide rails or lifts, but simplify them to cut costs.

- Gating:

Choose a hidden door (such as a tunnel door) to avoid surface markings; The position of the gate affects the filling mode.

- Cooling channels: Designed for efficient and uniform cooling, it shortens the cycle and prevent warping.

- Ejection system: Utilizing pin ejection or air ejection, no damage is caused when handled gently and delicately.

- Surface finish: Specify the texture (for example, by electrical discharge machining or shot blasting) to replicate the grip or matte effect.

Mold materials: Hardened steel for large-scale operation (100,000+ cycles) or aluminum for faster and lower-cost prototypes. The manufacturing process involves CNC machining, electrical discharge machining, and polishing to achieve precision – invest wisely here for long-term success in plastic phone case manufacturing.

3.3 Material Selection & Preparation

Choosing the right plastic is of vital importance as it directly affects the appearance, touch, protection level, durability, and cost of the phone case. Each material has its unique advantages and disadvantages. Thorough material preparation, especially the drying and moisture-absorbing resin, is the key to preventing defects.

Common Phone Case Material Comparison:

| Material | Key Property | Best For | Note |

|---|---|---|---|

| PC | Superior Protection | Premium clear cases | Crystal clarity, impact-resistant • Prone to scratches • $$$ |

| TPU | Flexible Shock Absorption | Slim/grip cases | Soft, thin designs • Can yellow • $$ |

| ABS | Rigid & Paintable | Decorative/hard cases | Glossy finish • Less drop protection • $ |

| PP | Lightweight & Cheap | Budget cases | Chemical resistant • Poor UV stability • $ |

| PC/ABS | Balanced Performance | Hybrid cases | Mix of toughness/rigidity • Mid-cost • $$ |

Preparation:

- Drying: For hygroscopic materials such as pc, they must be dried at 120°C for 2 to 4 hours to prevent defects related to moisture.

- Additives: Masterbatches are used for coloring, UV stabilizers for anti-fading, and anti-scratch agents for durability.

- Material handling: Ensure consistent particle quality and avoid changes in melt flow.

3.4 Injection Molding Process Steps

The injection molding process mainly consists of the following three steps:

- Melt & Injection

Plastic pellets are sent into the hopper, melted in the bucket (200-300℃), and then rapidly injected into the mold cavity. This process needs to be filled quickly to avoid premature cooling. - Pressurization and Cooling

After injection, keep the additional material of the pressure pack to compensate for the contraction. Maintain the pressure for 5 to 10 seconds to avoid sinking marks. Optimize the cooling time (10-20 seconds) and use effective mold channels to prevent warping. - Mold Opening and Ejection:

After cooling, the mold is opened, and the ejection system gently pushes out the shell. Be careful to use pins or blowers to avoid damaging sensitive areas. At the same time, optimize the cycle time: The goal is to keep the total cycle time below 30 seconds to maximize the output.

3.5 Post-Processing

After molding, the aesthetics and functionality of the case need to be further refined:

Trimming

Use an automatic machine to punch holes and shape the keys on the phone case, and manually remove the burrs to make the phone case smoother

Surface Finishing

Common ways to enhance the appearance and durability of your phone case include:

Paint/Coating: Use UV-resistant paint for color or gloss treatment (avoid using on flexible TPU to prevent peeling).

Pad printing: Precisely adding logos or patterns.

Laser etching: Used for permanent branding or texturing.

Texture application: Completed through molds, reducing post-processing requirements.

3.6 Assembly & Quality Control

For multi-component housings (such as hard housings with TPU bumpers), assembly components:

Automated assembly: Use fixtures for consistency.

QC inspection: Conduct strict tests:

- Dimensional accuracy: Verify the mobile phone model with an instrument or a three-coordinate measuring machine.

- Visual inspection: Scan for defects such as cavities, burns or color mismatches.Functional testing: Ensure button responsiveness and port accessibility.

- Durability test: Perform drop tests (for example, from 1-2 meters) and flexibility assessment of the TPU.

- Consistency audit: Monitor batch samples to maintain standards.

This end-to-end process ensures that each phone case meets a high-quality benchmark and is well-prepared for market distribution.

Conclusion

Injection molding is an important method for mass production of mobile phone cases, providing unparalleled efficiency, precision, and scalability for success in the mass market. With the development of smartphone technology, the innovation of plastic injection molding will keep your products competitive.

Are you ready to optimize yours? Start with a detailed mold design review – your journey to the perfect phone case begins here.

.webp)