Finding a reliable phone case manufacturer in today’s highly competitive accessories market can be a formidable task. The constantly rising environmental protection standards, strict design patent requirements, and consumers’ extremely high expectations for product quality have all increased the complexity of this process.

Common pitfalls include sample mismatches, large orders, delays caused by false certifications, or stockouts during peak seasons, thereby undermining business opportunities.

This guide goes beyond simple price and sample checks and offers a complete linked evaluation system covering qualifications, production, and after-sales service.

Let’s start from the basics – three core indicators to help you quickly screen out unqualified candidates and focus on potentially reliable phone case manufacturers.

2 Basic Metrics to Screen Phone Case Manufacturers

Table of Contents

ToggleCompliance Qualifications

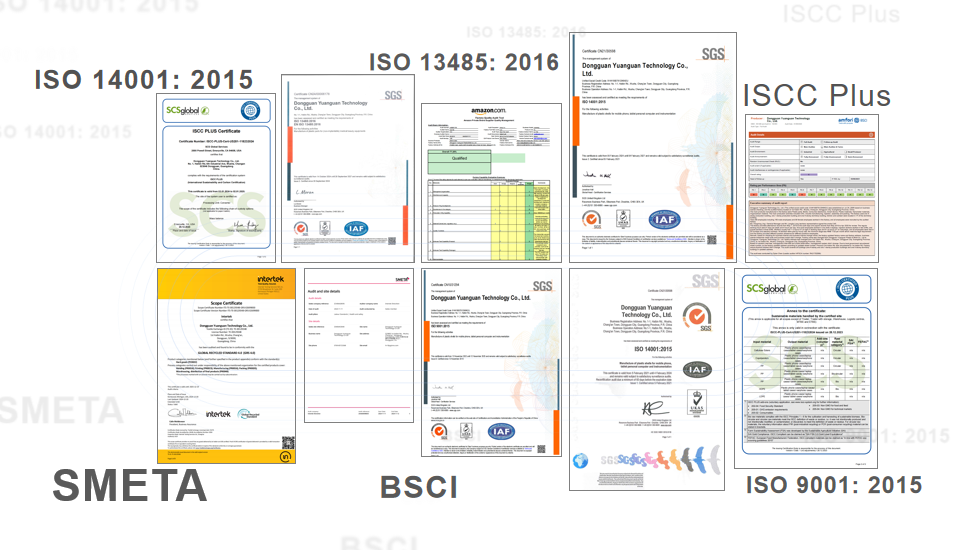

Compliance certification is of vital importance to any reputable phone case manufacturer. Core qualifications typically include internationally recognized certifications such as ISO9001, ISO14001, BSCI, and GRS, which reflect the degree of the supplier’s overall standardized operation and compliance awareness.

For the screening process of mobile phone case manufacturers, ensuring the possession of these key compliance certificates is a fundamental threshold. Such qualifications can serve as preliminary proof that the supplier can meet industry and market regulatory requirements.

When evaluating a reliable mobile phone case manufacturer, one should be cautious about enterprises that cannot provide complete or valid compliance certification documents, as this often indicates an insufficient degree of operational standardization.

Production Capacity

After confirming compliance, capacity matching is the key next step in choosing a phone case manufacturer that suits your business.

Focus on key assessment data: the matching degree between the minimum order quantity (MOQ) and your purchasing scale, the daily output of each production line, and the capacity during peak seasons.

Test the flexibility of mobile phone case manufacturers by asking them if they can handle combined orders of “small-batch trial production + large-batch make-up orders”. This indicates whether they can adapt to your business needs.

These basic indicators play a role in preliminary screening. By verifying compliance effectiveness and matching production capacity, you can efficiently eliminate underperforming phone case manufacturers, thereby saving time for subsequent in-depth evaluations.

Beyond the initial screening, the next step is to conduct an in-depth investigation of production capacity – this is the true manifestation of the quality of top mobile phone case manufacturers.

Quality Checks in Production

Material Control

Materials are the foundation of product quality. The best mobile phone case suppliers should have strict material control standards.

Request phone case manufacturers to provide material traceability: Inquire about the qualifications of raw material suppliers, such as BayerPC or DoWTPU authorization certificates.

Focus on key test items: heavy metal content, VOC emissions, and accelerated yellowing resistance tests (especially for clear phone cases)

Balancing cost and quality: Understanding why the same material has different prices – factors such as formula optimization and purity levels are crucial.

Process Details

Even if high-quality materials are used, rough craftsmanship may ruin the product. When evaluating a phone case manufacturer, please pay close attention to the process details.

Clarify the acceptance criteria for core processes.

Injection molding: No burrs, no shrinkage, button hole deviation <0.1 mm.

For the printing process: The pattern is free of burrs, and the abrasion resistance test shows no fading after more than 500 cycles.

For magnetic processes: Adsorption force ≥ 8N, magnetic attenuation ≤10% after long-term use.

Check the equipment investment of phone case manufacturers: Do they use automated inspection equipment (such as visual inspection devices) instead of only manual quality control? This will affect consistency.

Quality Control

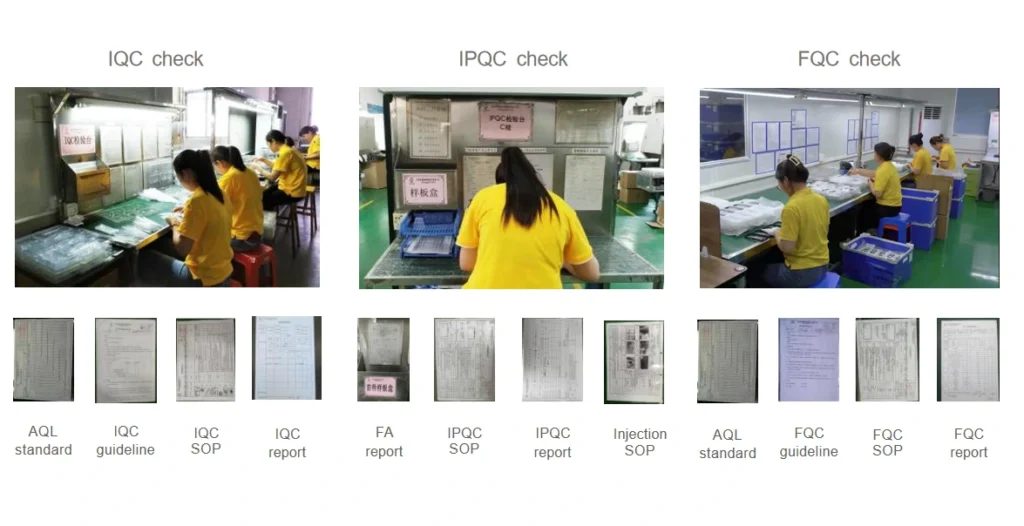

A sound quality control system ensures the consistency of the output. This is an indispensable feature of a reliable mobile phone case manufacturer.

Review the full-process quality control nodes, including the standard documents for incoming material quality control (IQC), First article inspection (FAI), process quality control (IPOC), and final quality control (FQC).

Understand the defective product handling methods of mobile phone case manufacturers: repair rate standards, as well as the process and time commitment for returning or replacing defective products.

Material control, craftsmanship, and quality control systems directly determine the quality of the products you receive from mobile phone case manufacturers. Do not neglect these in-depth inspection procedures.

Quality is the foundation, but smooth cooperation also relies on high-quality service. Let’s continue to explore how to evaluate the service capabilities of mobile phone case manufacturers to establish long-term cooperative relationships.

Evaluate Service Capabilities for Long-Term Cooperation

Customized Service

If you need OEM/ODM services, customization capability is the core criterion for choosing an ODM phone case manufacturer.

Discuss design collaboration: Inquire about the 3D modeling cycle, sample cost, and delivery time, as well as the limit on the number of modifications.

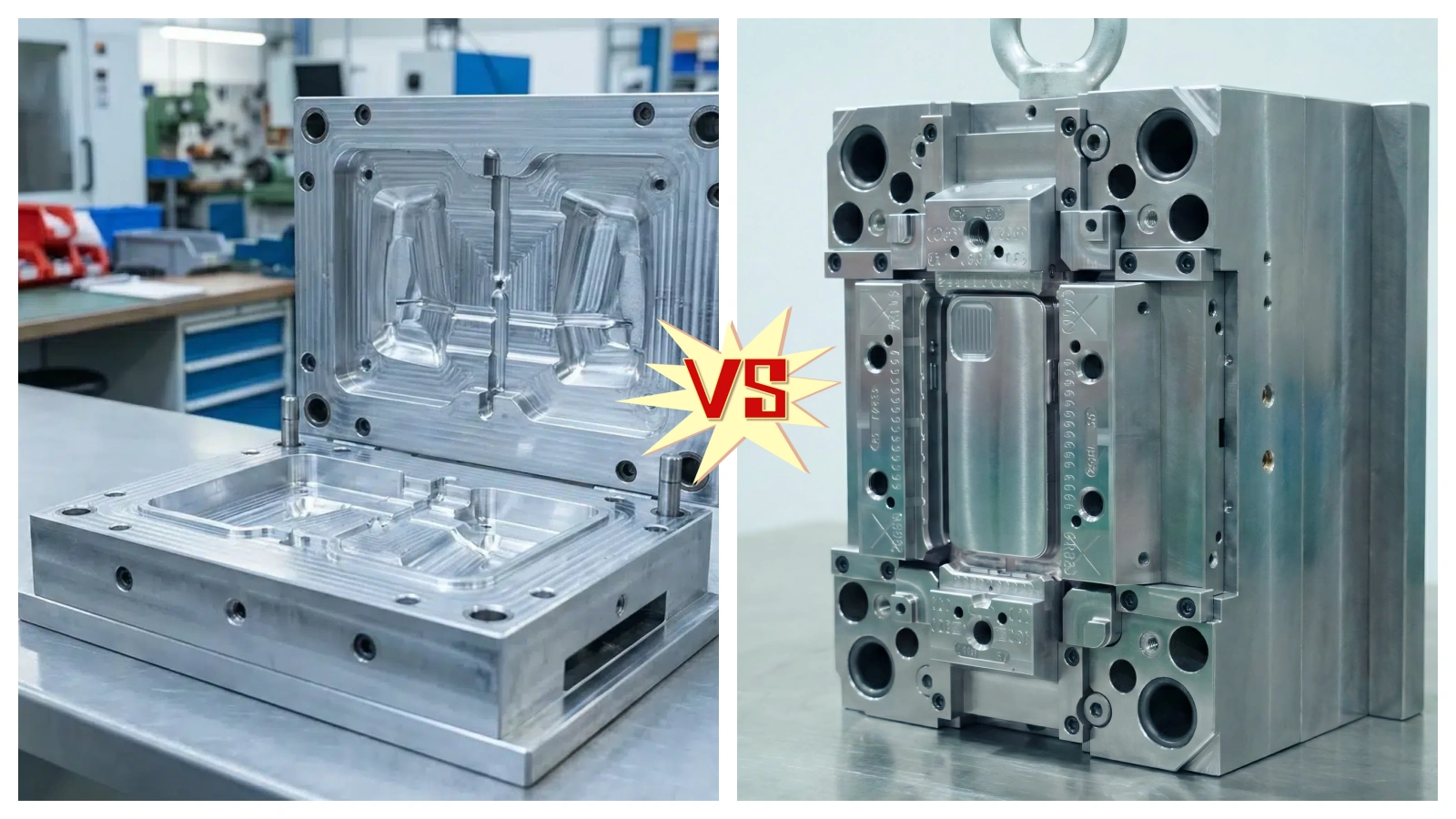

Clarify mold development: The promised mold service life and who bears the mold opening risks (such as rework responsibilities due to dimensional deviations)

Prioritize negotiating patent protection with phone case suppliers: Will they sign a Non-disclosure Agreement (NDA), and are the terms regarding the ownership of intellectual property rights clear?

Delivery service

Timely delivery is crucial to your business operations. Professional mobile phone case factories will have a mature delivery guarantee mechanism.

Decomposition delivery cycle: sample delivery period, production delivery period and logistics connection time.

Check the logistics support: Can they provide door-to-door (DDP) service and guarantee the logistics damage rate?

After-Sales Service

After-sales service reflects the responsibility of mobile phone case manufacturers. Efficient after-sales support can save you a lot of trouble.

Evaluate communication efficiency: Customer service response time (Is it within 24 hours?) And the closed-loop cycle for problem-solving.

Ask the manufacturer about the value-added services they offer: Do they provide product packaging design, barcode generation, or Amazon FBA warehousing support?

Abstract: Outstanding service capabilities – from custom support to delivery guarantee and after-sales efficiency – are the cornerstone for establishing a long-term partnership with a reliable mobile phone case manufacturer.

Now that you have learned how to evaluate phone case manufacturers, the next question is: Where can you find these high-quality candidate suppliers? The following are three effective procurement channels.

Channels to Find Top Phone Case Manufacturers

Online Platforms

Online platforms are the most convenient way to find phone case manufacturers, but you need to learn how to screen them effectively.

Pay attention to mainstream platforms: Alibaba Gold Supplier (preferably those with SGS on-site inspection marks) and Global Sources certified mobile phone case manufacturer suppliers.

Use filtering techniques: Reverse judge the stability of cooperation through the “transaction records” and “buyer Reviews” on the platform.

Offline Exhibitions

Offline exhibitions allow you to communicate face-to-face with representatives of mobile phone case manufacturers and inspect samples on the spot.

Mark key exhibitions: GlobalSources Electronics Show (Hong Kong), CES(USA), and IFA(Germany)

Prepare the communication list for the exhibition: on-site inspection of sample processes, request factory qualification documents, and arrange video factory inspections.

Industry Recommendations

Industry recommendations can help you find reliable phone case manufacturers more efficiently, thanks to the built-in endorsement of trust.

Explore connection channels: Join the Mobile Phone Accessories Buyers Association or get recommendations from logistics providers such as DHL.

Advantage utilization: These recommendations come with built-in cooperative endorsements, which can reduce the time cost of qualification verification for rival case manufacturers.

Abstract: Each procurement channel has its own advantages. Combining online screening, offline investigation, and industry recommendation can help you find your ideal first-class phone case manufacturer more quickly.

Finding potential candidates is only the first step. You need to conduct in-depth verification to confirm whether the phone case manufacturer is truly reliable. Here are five practical steps.

5 Steps to Confirm Manufacturer Reliability

Step 1: Test multiple product samples (at least 3 core products, with a test cycle of more than 7 days) to check the quality consistency of the mobile phone case manufacturer.

Step 2: Conduct a video factory inspection. Focus on the production workshop, quality inspection laboratory, and raw material warehouse.

Step 3: Arrange third-party testing. Entrust SGS/ TUV to conduct a comprehensive compliance test on the samples.

Step 4: Place a small-batch trial order (order quantity less than 10% of the regular purchase) to verify the consistency of delivery and quality.

Step 5: Review the contract terms with the phone case manufacturer. Pay close attention to quality standards, delivery time, compensation for breach of contract, and intellectual property terms.

Following these five steps can help you avoid risks and accurately determine whether the phone case manufacturer meets your cooperation requirements.

When screening reliable suppliers, you also need to be vigilant about the types of high-risk phone case manufacturers that may lead to losses. The following are four situations that should be avoided.

4 High-Risk Manufacturers to Avoid

Conclusion

The best phone case manufacturer = compliant qualifications + stable production capacity + strict quality control + efficient service. These four pillars ensure the smooth progress of cooperation and the competitiveness of products.

If you are looking for the best phone case manufacturer in China, YG is a choice worth considering.

YG’s strengths: As a mobile phone case manufacturer with over 10 years of experience, YG is dedicated to providing OEM/ODM services to global customers

- We support small-batch customized services and offer a one-stop solution from design to delivery.

- It has passed multiple certifications, such as ISO9001, ISO 14001, and ISCC PLUS.

- With a comprehensive quality inspection process and a quality inspection team, we ensure the consistency of product quality.