1. Introduction: Why Mold Costs Vary Widely

Table of Contents

ToggleIf you’re researching phone case mold costs, you’ve likely seen estimates ranging from $1,000 to over $5,000. This wide gap isn’t arbitrary – it reflects critical decisions that impact your product quality, scalability, and profitability.

As a phone case manufacturer with 12+ years of experience, we’ve helped 500+ brands navigate mold investments. In this guide, you’ll learn:

The hidden cost drivers most suppliers won’t explain

How to avoid overpaying for unnecessary features

A comparison table of mold costs for iPhone vs. Android cases

5 strategies our top clients use to save 30%+ on mold expenses

Let’s demystify the process.

2. 6 Key Factors Affecting Phone Case Mold Costs

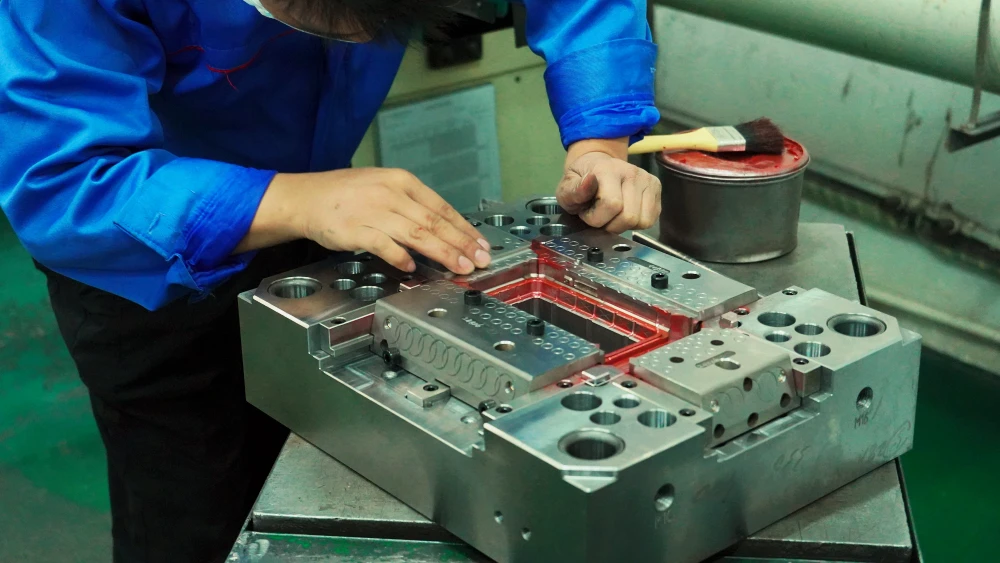

2.1 Material Choice: Steel vs. Aluminum Molds

Steel Molds (Hard Tooling)

Cost: $3,000 – $5,000

Lifespan: 500,000+ cycles

Best for: High-volume production (10k+ units)

Example: A steel mold for iPhone 16 Pro Max cases costs ~$4,200 but lasts 8x longer than aluminum for bulk orders.

Aluminum Molds (Soft Tooling)

Cost: $1,000 – $2,500

Lifespan: 10,000-50,000 cycles

Best for: Prototypes or limited editions (1k-5k units)

Pro Tip: Use aluminum for market testing – it’s 60% cheaper upfront.

Steel vs Aluminum Mold Cost Comparison

Alt Text: “Steel vs aluminum phone case mold cost and lifespan comparison chart”

2.2 Design Complexity

Complexity Level Cost Range Example

Basic $1,000-$2k Solid-color silicone cases

Intermediate $2k-$3.5k Two-tone TPU with logo embossing

Advanced $3.5k-$5k+ Magnetic cases with 3D animal textures

A client saved $1,700 by simplifying a dragon-scale design to a flat geometric pattern without sacrificing appeal.

2.3 Phone Model Compatibility

iPhone: Lower cost (standard CAD files available)

Rare Android Models: +15-30% cost due to custom measurements

Pro Tip: Design cases for upcoming models early – Apple often shares specs with certified manufacturers 6 months pre-launch.

2.4 Surface Finish Requirements

Glossy/Matte: Standard finish (no extra cost)

Custom Textures (e.g., leather, marble): +$300-$800

Mirror Polish: +$200 for premium brands

2.5 Order Volume Discounts

Quantity Price Per Mold

1-5k $3,000

5k-20k $2,600 (-13%)

20k+ $2,200 (-27%)

Based on steel molds for iPhone 16 cases

2.6 Turnaround Time

Standard (20 days): No extra fee

Rush (10 days): +25%

Super Rush (7 days): +40%

3. 5 Proven Ways to Reduce Mold Expenses

3.1 Simplify Your Design Early

Remove undercuts requiring sliding molds (-$800)

Avoid multi-color designs needing separate cavities (-$1,200)

3.2 Prototype with 3D Printing

Cost: $150 vs. $1,800 for aluminum mold

Client Example: A gaming brand avoided $4k in rework costs by prototyping a controller grip add-on.

3.3 Partner with Manufacturers Offering Design Reviews

We provide free DFM (Design for Manufacturing) analysis to:

Suggest thickness adjustments for easier demolding

Identify overly complex textures that inflate costs

3.4 Reuse Molds for Similar Models

iPhone 15 cases often work with iPhone 16 with minor port adjustments (-90% mold cost).

3.5 Negotiate Long-Term Contracts

Lock in rates for future models – our top clients get 15% off subsequent molds.

4. FAQ: Answering Your Top Concerns

Q1: Can the mobile phone case mold be reused to produce different models?

A: Partial reuse is possible! For example:

✅ iPhone 15 mold → iPhone 16 (adjust the position of the charging port, saving 80% of the cost)

🛠️ We provide mold modification services, the cost is only 30% of the new mold.

Q2: What is the minimum order quantity (MOQ) for custom molds?

A: No mandatory MOQ! Flexible solutions:

🔧 Small batch testing: 50-100 pieces (using aluminum molds, cost from $1,000)

🏭 Mass production: 1,000+ pieces (steel molds are recommended, the cost per piece is as low as $0.1)

📘 Check our small batch production guide to optimize costs

Q3: Are there any hidden costs in mold production?

A: Beware of these 3 common surcharges:

Design modification fee: adjustment after approval ($150/hour)

Mold storage fee: $200/year after 6 months

Export certification fee: EU/FDA certification $350

💡 Our quote includes a transparent fee list, no hidden terms

Q4: How long does it take to make a phone case mold?

| Stage | Duration |

|---|---|

| Design Review | 1-3 days |

| Mold Fabrication | 12-18 days |

| Sample Testing | 3-5 days |

Q5: Do you provide mold warranty?

A: Provide industry-leading warranty:

Steel mold: 2-year workmanship defect warranty

Aluminum mold: 6-month durability guarantee

5. Ready to Get Your Exact Mold Cost?

Claim Your Free Quote in 3 Steps:

Upload Your Design: PDF, AI, or 3D file

Select Preferences: Material, volume, timeline

Get Your Quote: Within 24 hours + 10% First-Order Discount

[ GET FREE QUOTE NOW]