Deciding between hot runner vs cold runner injection molding can feel like a costly gamble. The wrong setup leads to too much waste, slow production, and higher costs. This guide uses real factory experience to help you pick the best, most profitable path for your parts.

Why This Choice Matters

Table of Contents

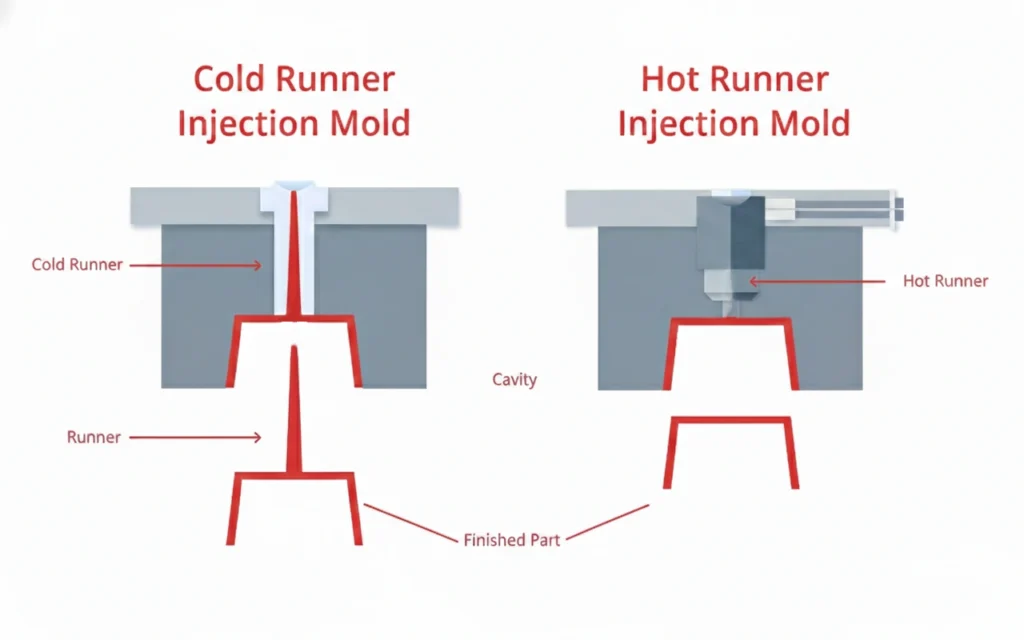

ToggleIn plastic manufacturing, your “runner” is the bridge that carries liquid plastic into the mold. While it sounds simple, the bridge you choose—hot or cold—determines your profit. Whether you are making medical parts or phone cases, understanding hot runner vs cold runner injection molding is the first step to a successful project.

Cold Runner System vs Hot Runner System

To make an informed choice, we must first strip away the marketing jargon and look at the physics of how plastic moves through a mold.

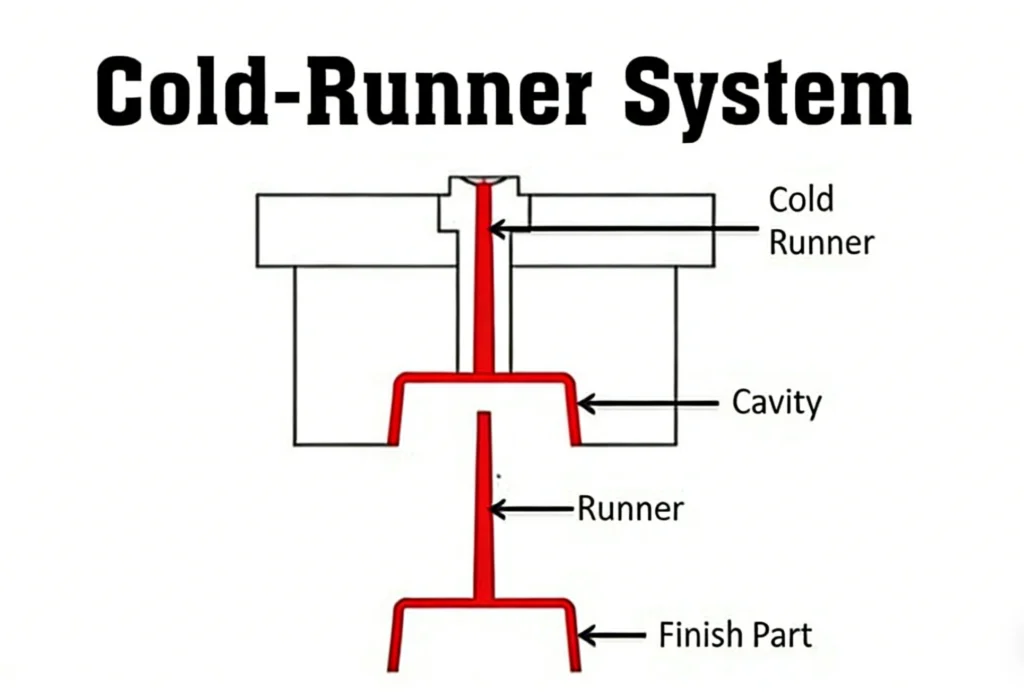

What is a Cold Runner System?

A cold runner system is the most common and straightforward setup in the industry. It consists of unheated channels carved directly into the mold plates. This simplicity makes it a favorite for prototyping and short-run injection molding projects where speed is more critical than material waste

How it works: Molten plastic enters the sprue, flows through the runners, and enters the gate into the cavity.

The Thermal Cycle: Because the mold is kept at a lower temperature to solidify the part, the plastic remaining in the runner also solidifies.

The Result: Every time the mold opens, it ejects both the finished product and the solidified “scrap” (the runner).

When designing cold runners, pay close attention to the runner-to-part weight ratio. If your runner weighs more than your part, you are essentially running a recycling business, not a manufacturing one. Optimize runner diameters to the minimum size required to fill the part without excessive pressure drop.

The Hot Runner System

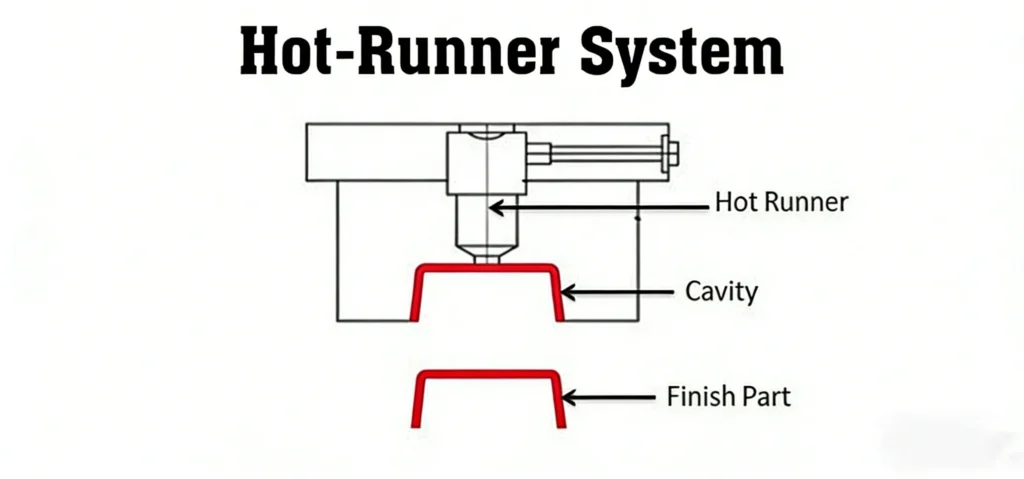

Think of a hot runner system as an extension of the injection molding machine’s heated barrel, moved inside the mold itself.

The Architecture: It utilizes a heated manifold and specialized heated nozzles to maintain the plastic in a molten state.

The Thermal Cycle: The manifold is internally or externally heated to stay above the material’s melting point. Only the plastic that enters the cooled cavity solidifies.

The Result: The mold opens, and only the finished part is ejected. The plastic for the next shot stays liquid in the runner, ready to flow.

Precision is the soul of a hot runner system. Always use a high-quality, multi-zone temperature controller. Even a 5 °C fluctuation can cause material degradation or “drooling” at the gate, leading to cosmetic defects that require expensive manual sorting.

Mechanism Summary Table

| Feature | Cold Runner System | Hot Runner System |

| State of Plastic in Runner | Solidifies every cycle | Remains molten (liquid) |

| Secondary Processes | Requires trimming or recycling | Ready to use (No trimming) |

| Thermal Control | Passive cooling | Active (Heaters & Thermocouples) |

| Pressure Drop | High (due to cooling friction) | Low (consistent flow) |

The Pros and Cons of hot runner injection molding and cold runner injection molding

Every system has trade-offs. Here is the honest breakdown of what happens on the factory floor.

Cold Runner Injection Molding: Simple and Reliable

Advantages :

Lower Cost: The cost of mold is much lower.

Easy Fixes: Any mold technician can maintain it.

Easy Color Changes: Switching colors is fast because the old color is ejected every cycle.

Great for Prototypes: Best for prototyping and short-run injection molding projects.

Disadvantages :

Lots of Waste: You create a lot of plastic scrap that needs recycling.

Slower Cycles: You have to wait for the thick runner to cool before opening the mold.

Extra Labor: Someone (or a robot) must clip the parts off the runner.

Hot Runner Injection Molding: Fast and Efficient

Advantages :

Zero Waste: You only pay for the plastic that becomes a finished product.

Faster Production: No runner to cool means the machine cycles much faster.

Better Quality: It uses less pressure, which means fewer sink marks or warped parts.

Automation Ready: Parts are ready to pack immediately.

Disadvantages:

High Price Tag: The mold can cost 50% more due to the heating system.

Hard to Maintain: If a heater fails, production stops. You need an electrician or a specialist.

Hard Color Changes: It can take hours to clean the old color out of the heated manifold.

How to Choose the Right System

Use these three factors to make your decision.

1. How Many Parts Are You Making?

Small Batches (<20,000 parts): Go with a cold runner. The low mold price is more important than the plastic waste.

Mass Production (>100,000 parts): A hot runner is the winner. The faster speed and zero waste will save you thousands of dollars.

2. What Materials Are You Using?

Expensive Resins: If your plastic is pricey (like PEEK), use a hot runner. You cannot afford to throw away expensive scrap.

Heat-Sensitive Plastic: Some plastics (like PVC) can burn if they stay hot for too long. Cold runners are safer for these materials.

3. How Does the Part Need to Look?

Perfect Finish: For premium products, a hot runner leaves a nearly invisible mark where the plastic entered.

Standard Finish: A cold runner leaves a small “stub” that must be trimmed, which might leave a visible scar.

Factory Tips: Common Mistakes to Avoid

Here is what we’ve learned from 30 years on the factory floor.

The Color Change Trap

In a cold runner, changing colors takes 15 minutes. In a hot runner, it can take 3 hours. If you need to change colors every day, a hot runner might actually cost you more in “downtime” than it saves in plastic.

Managing Gate Marks

The “gate” is where plastic enters the part. If you need a clean, flat surface, look into a Valve Gate hot runner. It uses a mechanical pin to shut off the flow perfectly, leaving a “beauty gate” that is perfect for consumer electronics.

The Truth About Recycling

Many people think cold runners are fine because they can “regrind” the scrap. But regrind plastic is never as strong as new plastic. For high-quality custom mold design and tooling, you usually can only use 15% regrind. If your runner is big, you will eventually have more scrap than you can reuse.

A Quick Look: Side-by-Side Comparison

While cold runners save you money on day one, hot runners are designed to save you money on every single part you produce afterward. Choosing the right one is a balance between your available budget today and your goal for profit tomorrow.

| Metric | Cold Runner System | Hot Runner System |

| Startup Cost | $ (Low) | $$$ (High) |

| Material Waste | High (Requires recycling) | Zero to Minimal |

| Cycle Speed | Slower (Limited by runner) | Faster (Limited by part) |

| Labor Needs | Higher (Clipping/Sorting) | Lower (Fully automated) |

| Maintenance | Simple Mechanical | Complex Electrical |

| Best For | Short Runs & Prototyping | High-Volume Mass Production |

Think of a cold runner as “paying as you go” through material waste, while a hot runner is an “all-in” investment that lowers your long-term costs. If your project will run for more than a year, the hot runner is almost always the more profitable choice.

Conclusion

There is no “winner” in the hot runner vs cold runner injection molding debate. It all depends on your goals.

Choose a Cold Runner if you are testing a new product or have a tight budget.

Choose a Hot Runner if you are running 24/7 and need the lowest cost per part.

Expert Final Advice: Don’t just look at the mold quote. Ask your supplier for a “Total Cost” report that includes the cost of plastic waste over 100,000 parts. Often, the “expensive” hot runner mold is actually the cheapest option over time.

Ready to start your next project? At YG, we don’t just build molds; we engineer solutions. Whether you need a simple cold runner for a new prototype or a high-cavitation hot runner for global distribution, our team is ready to optimize your ROI. Contact us today for a free DFM (Design for Manufacturing) analysis.

FAQ

Q: Can I recycle all cold runner waste?

A: Yes, but it takes labor to grind it up, and using too much recycled plastic can make your parts weak.

Q: Why do hot runners cost so much more?

A: You are paying for a complex electrical system inside the mold—heaters, sensors, and a manifold—that must be precision-engineered.

Q: Which one is better for thin parts?

A: Hot runners are better for thin walls because the plastic stays hot and flows into small gaps more easily.

Q: What is a “Three-Plate” mold?

A: It is a special type of cold runner that automatically cuts the part away from the runner. It’s a good middle-ground if you want automation but cannot afford a hot runner.

.webp)