High material waste and sluggish cycle times are the silent killers of manufacturing margins. Traditional cold runner systems often leave you with “disposable” plastic channels that drive up labor costs and strain your machines. For those targeting high-precision markets, these inefficiencies aren’t just annoying—they are a bottleneck to scaling.

Hot runner injection molding is the high-performance upgrade that changes the game. By keeping plastic molten throughout the entire system, this technology delivers surgical part consistency and lightning-fast cycles. This guide breaks down the mechanics, the ROI, and the strategic choices you need to make to stay ahead in 2026.

What Exactly is a Hot Runner System?

Table of Contents

ToggleA hot runner system is a specialized component used in the plastic injection molding process. Its primary design purpose is to maintain a perfectly consistent temperature in the channels or “runners” through which molten plastic flows into the mold cavity.

In a conventional injection molding system, the plastic is injected through a sprue, which leads to a cold runner system. These cold runners are essentially a set of channels that distribute the plastic, but must be cooled and removed as solid waste after every cycle.

In contrast, a hot runner system eliminates the need for a cold runner by using heated channels. These channels and nozzles are heated to maintain the plastic in a molten (liquid) state throughout the entire injection process. Essentially, the system acts as a high-tech extension of the machine’s barrel, keeping the material ready for the next shot immediately.

How the Hot Runner System Works

The big selling point of hot runners is their ability to heat the entire runner system with an adjustable temperature controller. This ensures that the plastic stays in liquid form as it moves through the mold.

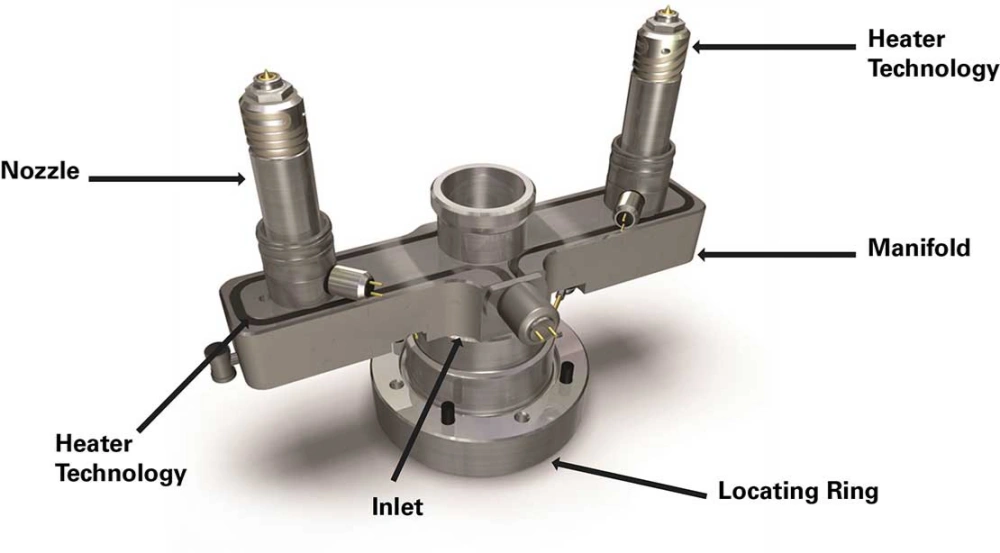

The Core Components

To achieve this level of precision, the system relies on three main parts working in perfect synchronization:

- Heated Barrel: Keeps the plastic resin at its initial processing temperature.

- Manifold: A heated block with multiple channels that shares out the molten plastic to various parts of the mold.

- Nozzles: The final “gateways” that deliver the molten plastic directly into the mold cavities.

These components work together to keep the plastic hot until the cavities are completely filled. Once filled, the part is allowed to cool and set into the shape of the mold before ejection.

Why Precise Temperature Control is Critical

Success in hot runner injection molding depends entirely on thermal stability. Precision is vital for several expert-level reasons:

- Material Quality: Different plastics have specific temperature requirements. Precise control ensures proper flow, viscosity, and homogeneity while preventing material degradation.

- Part Consistency: Deviations in temperature can lead to variations in dimensions, warping, or sink marks. Tight control allows manufacturers to produce parts that consistently meet specifications.

- Cycle Time Optimization: Efficient heat management enables precise timing of the cooling and solidification processes. By accurately controlling the temperature, the overall production cycle is shortened, increasing productivity.

- Energy Efficiency: Maintaining temperature within a narrow range avoids energy wastage from excessive heating or cooling.

- Process Stability: Stability reduces the likelihood of process variations, making it easier to fine-tune parameters for reliable production.

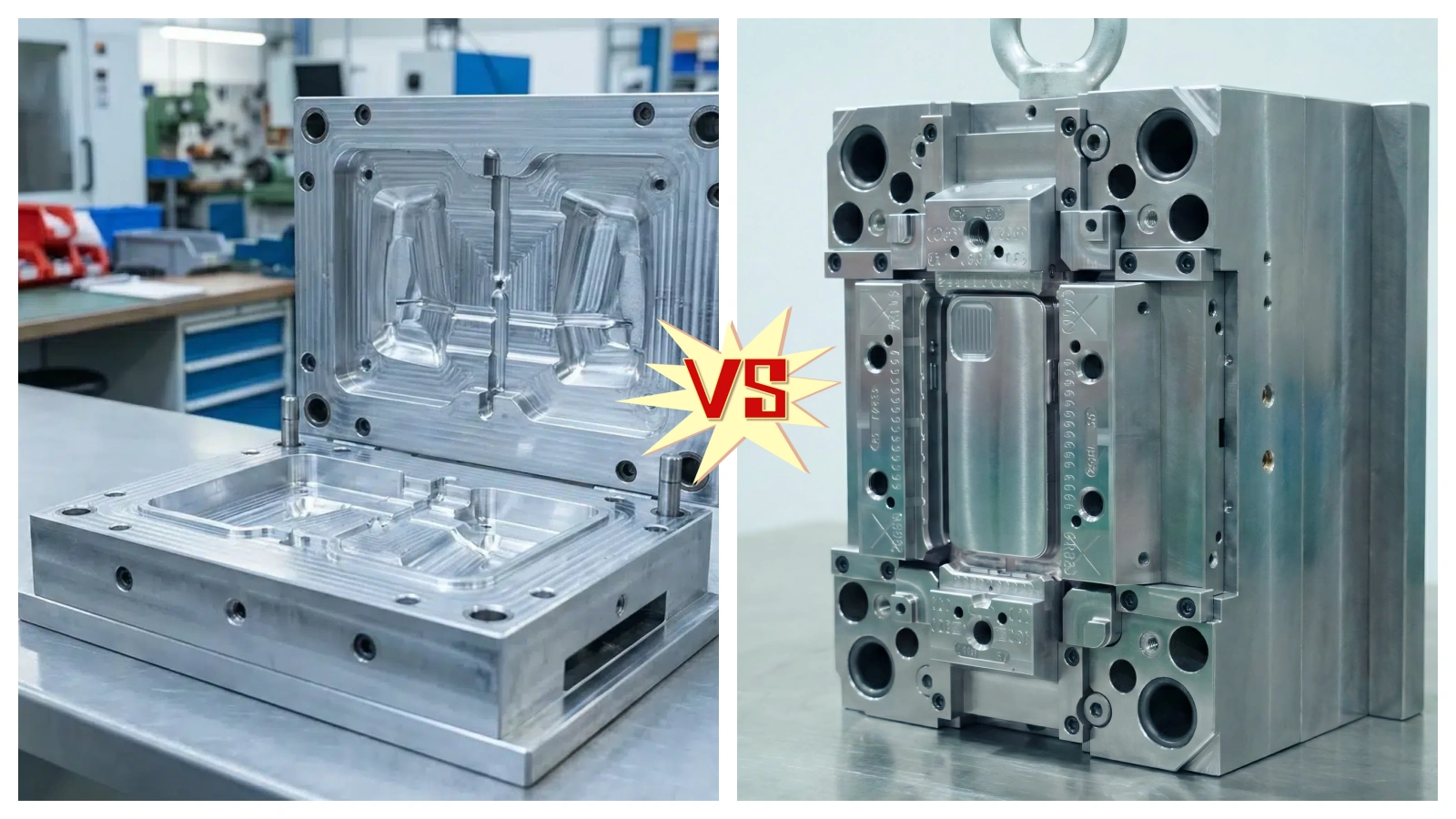

The Main Types of Hot Runner Systems

Selecting the right gate design is a critical engineering decision that affects your part’s aesthetics, internal stress, and overall production stability. In the world of hot runner injection molding, we categorize these systems into two primary types based on their gating mechanism.

Open Gate Systems

Open gate systems are the most common and versatile choice for general manufacturing. In this setup, the molten plastic flows through a permanently open orifice into the mold cavity.

Within this category, there are two specialized styles:

Hot Tip Systems: These use a heated tip at the end of the nozzle to precisely adjust the temperature at the gate. They are ideal for small to medium-sized parts with gate diameters between 0.5 and 2.0mm.

- Sprue Systems: These feature a larger passage (the sprue) that delivers plastic at lower pressure. This results in a lower shear rate, which significantly reduces internal stress and the risk of the part warping.

Best for: Industrial components, structural parts, or projects where a small, visible gate mark is acceptable.

Valve Gate Systems

For high-end precision parts, the valve gate is the “gold standard.” This system utilizes a mechanical needle—driven by pneumatic, hydraulic, or mechanical pressure—to physically open and close the nozzle.

- Mechanical Precision: The needle shuts the flow off flush with the part surface, effectively “sealing” the gate.

- Aesthetic Perfection: Because the gate is mechanically closed, it results in a perfectly smooth cavity with no defects, weld marks, or “stringing”.

- Multi-Gate Control: This type is essential for larger parts that require multiple gates to be controlled individually for balanced filling.

Best for: High-end consumer electronics (like phone cases), medical devices, and any application requiring a flawless, “no-trace” finish.

Comparison: Open Gate vs. Valve Gate

| Feature | Open Gate (Hot Tip/Sprue) | Valve Gate System |

| Control Method | Thermal (Temperature-based)

| Mechanical (Needle movement)

|

| Gate Vestige | Small visible mark or sprue

| Nearly invisible/perfectly smooth

|

| Complexity | Lower; easier to design

| Higher; requires complex actuators

|

| Ideal For | High-volume industrial parts

| High-precision/Medical/Aesthetic parts |

Actionable Advice

- Prioritize the Surface Finish: If your product is “consumer-facing” (like a high-end electronic enclosure), don’t compromise—invest in a Valve Gate system to avoid the cosmetic defects common in open gates.

- Match Volume to Gate Style: For massive production runs where aesthetic marks are hidden (internal structural parts), the Sprue System offers the best balance of low stress and high durability.

- Consult Early: Gate size and shape depend on part weight and material quality. Always involve your hot runner manufacturer in the initial design phase to ensure the gate material matches your resin’s behavior.

Advantages and Disadvantages of the Hot Runner System

While hot runners are a significant upgrade, they represent a strategic commitment. You must weigh the long-term efficiency against the higher initial costs.

The Advantages

- Cost Savings: In the long run, it is more cost-efficient due to reduced waste and better productivity.

- Reduced Waste: There are no runners to remove after each cycle, cutting waste right down.

- Faster Production: Once heated, the system doesn’t need prep time for the next injection, drastically lowering cycle times.

- Cleaner Parts: No extra plastic waste means cleaner parts that don’t interfere with robots or conveyors, with less chance of “flash” (excess plastic).

- Compatible with Delicate Materials: Precise heat control makes it easier to work with materials that have specific temperature requirements.

- Less Mold Stress: Less force is needed to inject plastic, meaning less stress on the mold and the machine.

The Disadvantages

- Higher Upfront Cost: They are generally more expensive to buy than cold runners.

- High Maintenance: Looking after these complex systems requires a lot of time and effort.

- Operating Costs: They require extra heating elements and sources, which can increase daily expenses.

Hot Runner vs Cold Runner Injection Molding

The choice between hot and cold runners often depends on your production volume and the complexity of the final part.

| Feature | Cold Runner System | Hot Runner System |

| Material State | Plastic cools and hardens in the runners.

| Plastic stays molten inside the system.

|

| Waste Generation | High runners must be removed and discarded.

| Minimal to none; eliminates the sprue and runner system.

|

| Complexity | Relatively simple and cost-effective design.

| More complex; requires heaters and controllers.

|

| Part Quality | Higher risk of gate vestiges and inconsistency. | Better quality due to consistent, controlled temperatures.

|

| Speed | Slower; requires cooling of the runner section.

| Faster; cycles are brought down significantly.

|

Applications of Hot Runner Injection Molding

Hot runner injection molding projects encompass a massive range of global industries, demonstrating the sheer versatility of the technology.

- Medical Field: Used for intricate parts in medical devices like syringes, inhalers, surgical instruments, and IV components.

- Automotive Industry: Essential for producing high-quality interior components, exterior parts, and engine components with dimensional accuracy.

- Packaging Industry: Extensively used for bottle caps, containers, closures, and lids to ensure consistent quality with minimal waste.

- Consumer Goods: Mass production of electronics, toys, and household appliances benefits from eliminating cold runners.

- Industrial Sector: Manufacturing critical components like connectors, valves, gears, and enclosures where flow control is vital.

Critical Design Factors & Maintenance Management

You cannot treat a hot runner system like a standard piece of hardware. It requires a proactive engineering and upkeep strategy.

Design Best Practices

Manufacturer Partnership: Each hot runner system has unique requirements. Involve the manufacturer in the design process from the start to ensure proper operation.

- Application-Specific Configuration: Design varies based on whether the system gates directly to the part or uses a sub-runner. Configurations also change for high-volume or high-temperature needs.

- Material and Color: The type of material and color requirements impact the suitable hot runner type.

- Technical Specifications: Pay close attention to the nozzle hot tip’s material and shape, as well as the gate size, which depends on part weight and wall thickness.

Maintenance Strategy

Maintenance is the “high-effort, high-reward” price of efficiency.

- Thermal Protection: Reducing heat to the nozzle during pauses prevents faulty parts.

- Energy Efficiency: Energy-efficient systems reduce operational costs and contribute to environmental sustainability.

- Operational Benefits: While cost is a major factor, the benefits of faster cycles and zero waste often outweigh the initial expense.

FAQ

Q1: Is a hot runner system more expensive than a cold runner system?

A: Yes, the upfront cost is higher due to complex components like heated nozzles and manifolds. However, they often pay for themselves through faster cycles and zero material waste.

Q2: Does hot runner molding produce much waste?

A: No. They are generally known for producing less waste because they eliminate the need for a sprue and runner system.

Q3: Can hot runners handle delicate materials? A: Yes. Their efficient use of heat makes it easier to work with materials that have very specific temperature requirements.

Q4: What is the main selling point of these systems?

A: The ability to keep plastic in a liquid form throughout the process, leading to higher quality parts and faster production cycles.

Choose YG for Your Manufacturing Projects

Navigating the complexities of hot runner mold design requires a partner who understands high-precision manufacturing. At YG, we specialize in comprehensive ODM and OEM services, bridging the gap between innovative design and flawless execution.

Tailored Engineering: We go beyond standard solutions, providing custom plastic mold making and injection molding services tailored to your specific project requirements.

Global Standards: Our quality control and technical specifications align with the most demanding international standards.

Precision and Reliability: Our expertise in complex tooling ensures that your hot runner systems are optimized for long-term stability and maximum ROI.

One-Stop Service: From initial design involvement to final mass production, YG acts as an extension of your engineering team to ensure every part meets the highest dimensional accuracy.

Ready to Optimize Your Production?

Don’t let outdated molding methods slow your growth. Whether you are developing a new medical device or scaling a consumer electronics project, our team is ready to help you implement a high-performance strategy.

Contact YG Today for a Custom Quote. Let’s build your next high-precision project together.

.webp)