Introduction

Table of Contents

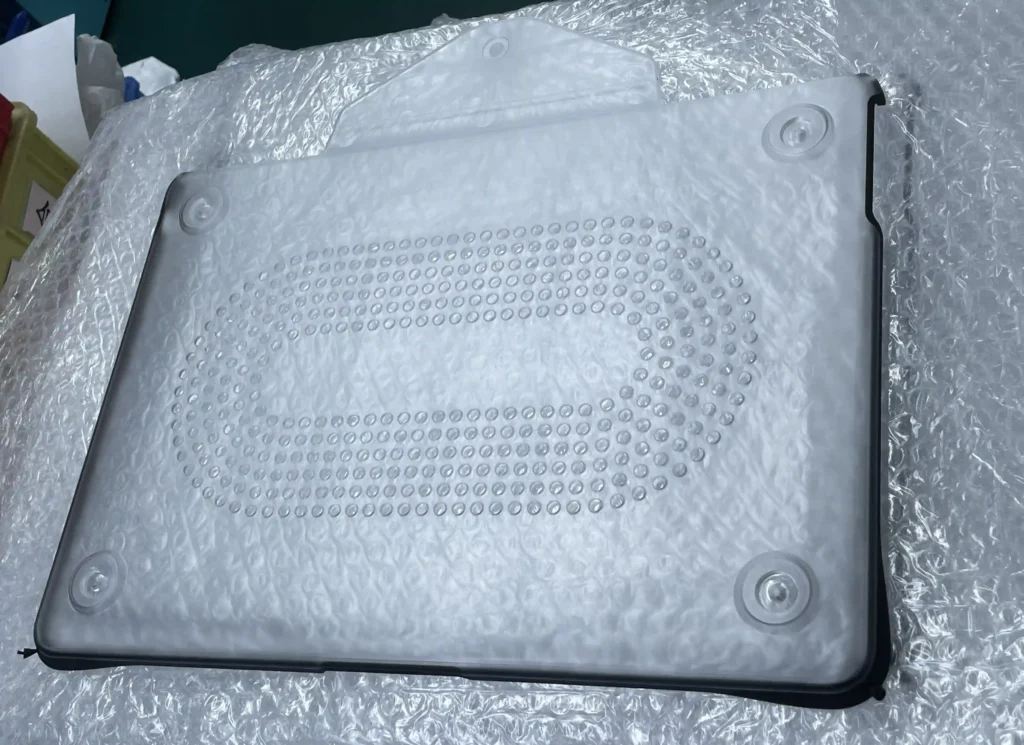

ToggleA well-known North American electronics brand aims to develop a laptop hard shell case, specifically designed for frequent travelers and academic professionals. This group of people prioritizes the safety of the equipment during transportation, but rejects bulky solutions that compromise portability. Therefore, they hope to offer a solution that can balance adequate protection, portability, and aesthetics.

However, to turn this concept into reality, a partner with innovative R&D capabilities is needed. The client needs a reliable laptop case manufacturer to handle issues such as design iteration, material optimization, and mass production.

Challenge: Difficult to Balance the Durability and Aesthetics

They need a plastic laptop case, which can:

- Maintain a thickness of less than 3mm at a drop of 1.5 meters

- Maintain lasting transparency and clarity, without yellowing for more than 12 months

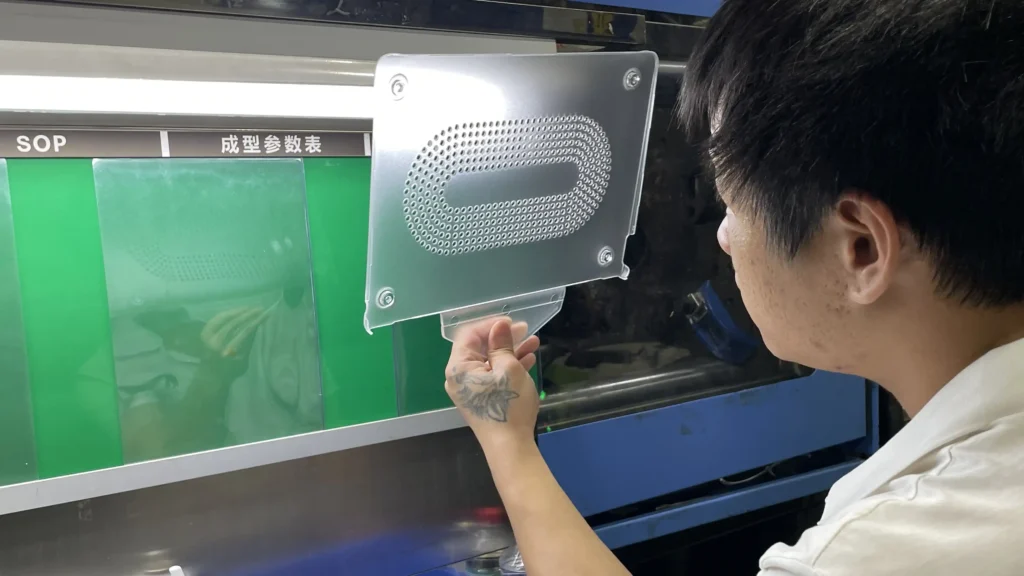

- Precise hole opening ensures a precise fit between the casing and the computer

- Offer logo customization services

- Design dedicated ventilation holes for effective heat dissipation

As a custom laptop case maker, YG faced a critical challenge: most plastic laptop case suppliers couldn’t achieve this balance. Compromises in shock absorption, clarity, or fit were industry norms.

Solution: Achieved through Material and Process Innovation

1.PC+TPU Synergy: The Combination of Science and Protection

YG’s materials team designed a hybrid structure that leverages the complementary strengths of the two polymers. Bayer Makrolon® polycarbonate from Germany forms a rigid base layer, providing dimensional stability and scratch resistance. Meanwhile, thermoplastic polyurethane (TPU) encapsulation and honeycomb reinforcement of the bumper perimeter. This strategic combination brings three key advantages to the laptop case:

- Military-grade drop protection (1.5m impact resistance, MIL-STD-810G certified)

- Near-perfect clarity (92% light transmission) with <5% yellowing after 12 months

- Microscopic scratch resistance (3H pencil hardness via nano-coating)

Unlike traditional single-material solutions, this structure answers the question “Which material is best for a laptop cover?” by balancing the rigidity of key stress points and the flexibility of impact areas.

2. Precision Mold Making

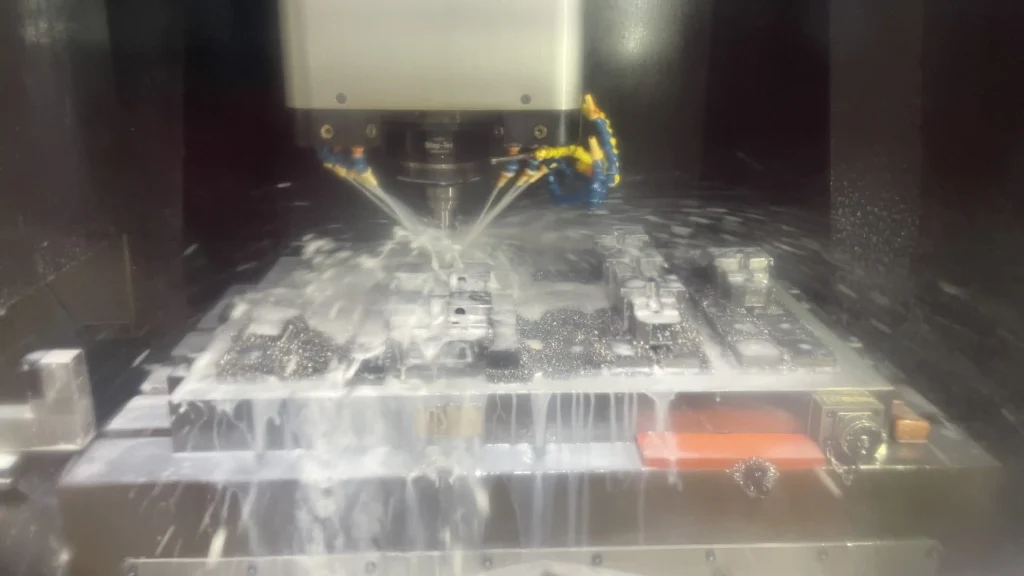

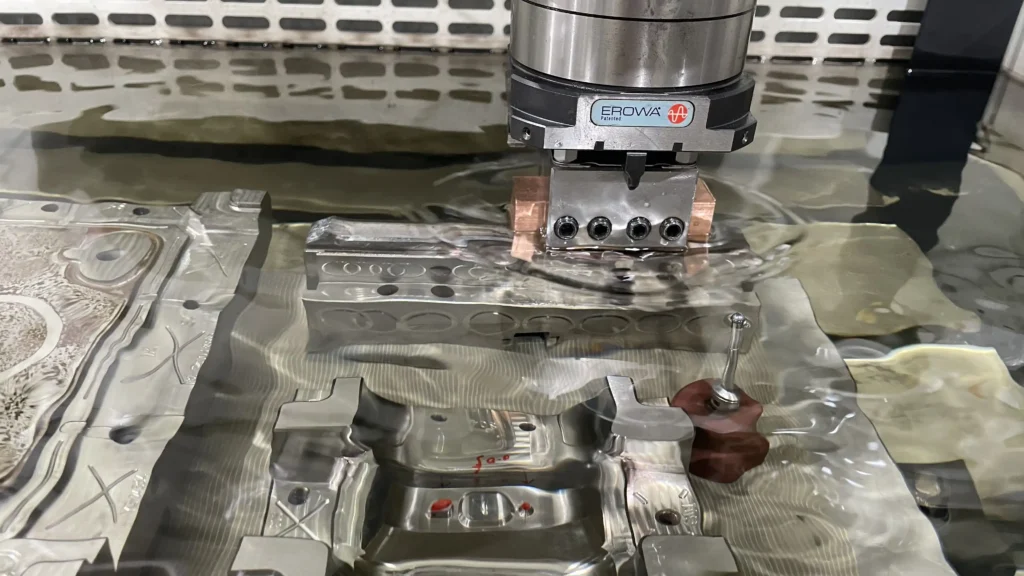

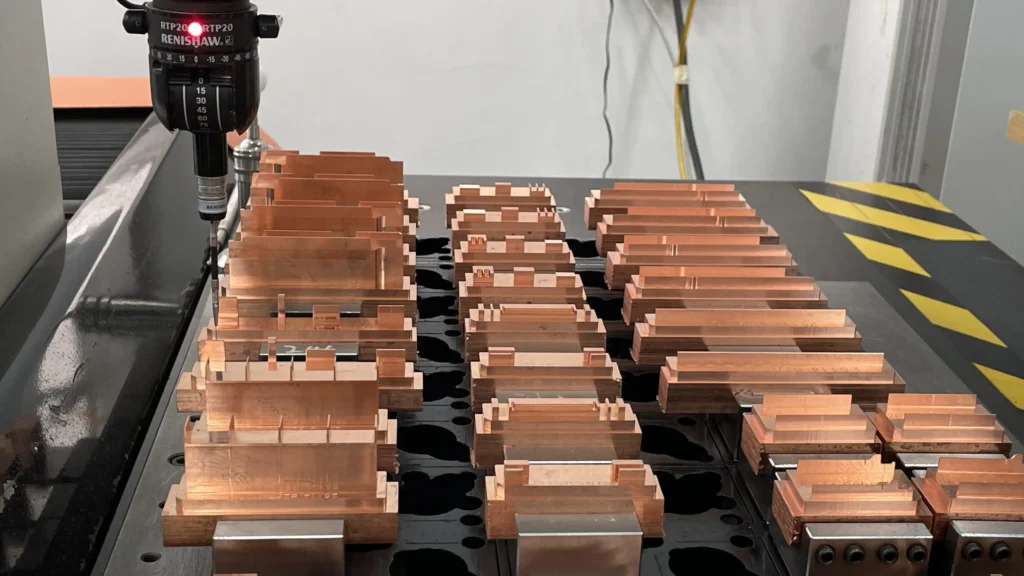

To achieve the required sub-millimeter precision, YG has deployed a multi-stage manufacturing protocol:

- Through EDM and CNC machining, we can produce high-precision molds with ±0.05mm.

- Make sure the charging ports and function keys are perfectly aligned with a 3-dimensional meter.

These processes transformed the concept of laptop cases from a commodity into a precisely designed accessory.

3. Custom Laptop Case With Logo

Responding to the client’s need for discrete yet durable branding, YG implemented automated pad printing technology instead of conventional laser engraving. This approach:

- Applies epoxy-based inks directly onto curved side surfaces

- Maintains 4B adhesion strength under accelerated abrasion testing

- Operates at ambient temperatures, preventing TPU deformation

For brands exploring how to make a custom laptop case with logo, this approach can achieve high-resolution branding while maintaining structural integrity.

Results: Beyond Specifications

| Metric | YG’s Performance | Client Impact |

|---|---|---|

| Weight Reduction | 89g (37% lighter than competitors) | ↑Portability & user satisfaction |

| Durability | 0% failure in 1.5m drop tests | ↓50% warranty claims |

| Customization | 5-day sampling; 15-day bulk lead time | Faster market entry |

| Clarity Retention | <5% yellowness after 12 months | ↓Returns due to discoloration |

These outcomes establish YG among the few companies making hard shell cases for laptop protection that balance technical excellence with aesthetic preservation.

Client Testimonials

“As a designer at a Top 3 electronics brand, I’ve audited 12+ laptop case manufacturers. YG’s solution stood out with zero tolerance deviations on port cutouts – something others promised but never delivered. Their side-printed logos survived 18 months of backpack abrasion without fading.”

Why Partner with YG

1. Provide one-stop ODM solutions

Unlike most custom laptop hard shell cases manufacturers, YG has over 30 years of experience in precision manufacturing:

- End-to-end control from prototype design to third-party logistics.

- Complies with ISO 9001/14001 and RoHS standards.

- Capacity of 30,000 units/day, reserved production line.

2. Accurately Address Clients’ Pain Points

- Thermal management: Separate vents to prevent overheating.

- Aesthetically pleasing and durable: The anti-fingerprint coating maintains “out-of-the-box” clarity.

- offer a variety of printing methods, including pad printing, UV printing, IML, and laser engraving.

Your Turn: How to Create a custom laptop case with logo

YG’s solution proves that PC+TPU composites are the answer to “Which material is best for a laptop cover?”. By combining material science with CNC precision and automated pad printing, we deliver what generic suppliers can’t: lightweight armor that looks premium and lasts.

For brands seeking a laptop case manufacturer that bridges innovation with scalability, YG turns specs into shelf-ready excellence.

Contact YG’s ODM Team to Initiate Your Project now.