About the Project

Table of Contents

ToggleThis project was initiated by a leading medical technology brand focused on enhancing the daily lives of diabetic patients through high-performance protective solutions. The goal was to bridge the clinical requirements of medical devices with the rugged demands of an active lifestyle, creating a protection system that remains slim yet virtually indestructible.

The core of the initiative involved a deep engineering study of insulin pump usage in high-activity environments. The project aimed to address common failure points in existing accessories—such as clip breakage and impact damage—by designing a custom, reinforced housing that ensures device stability and long-term durability.

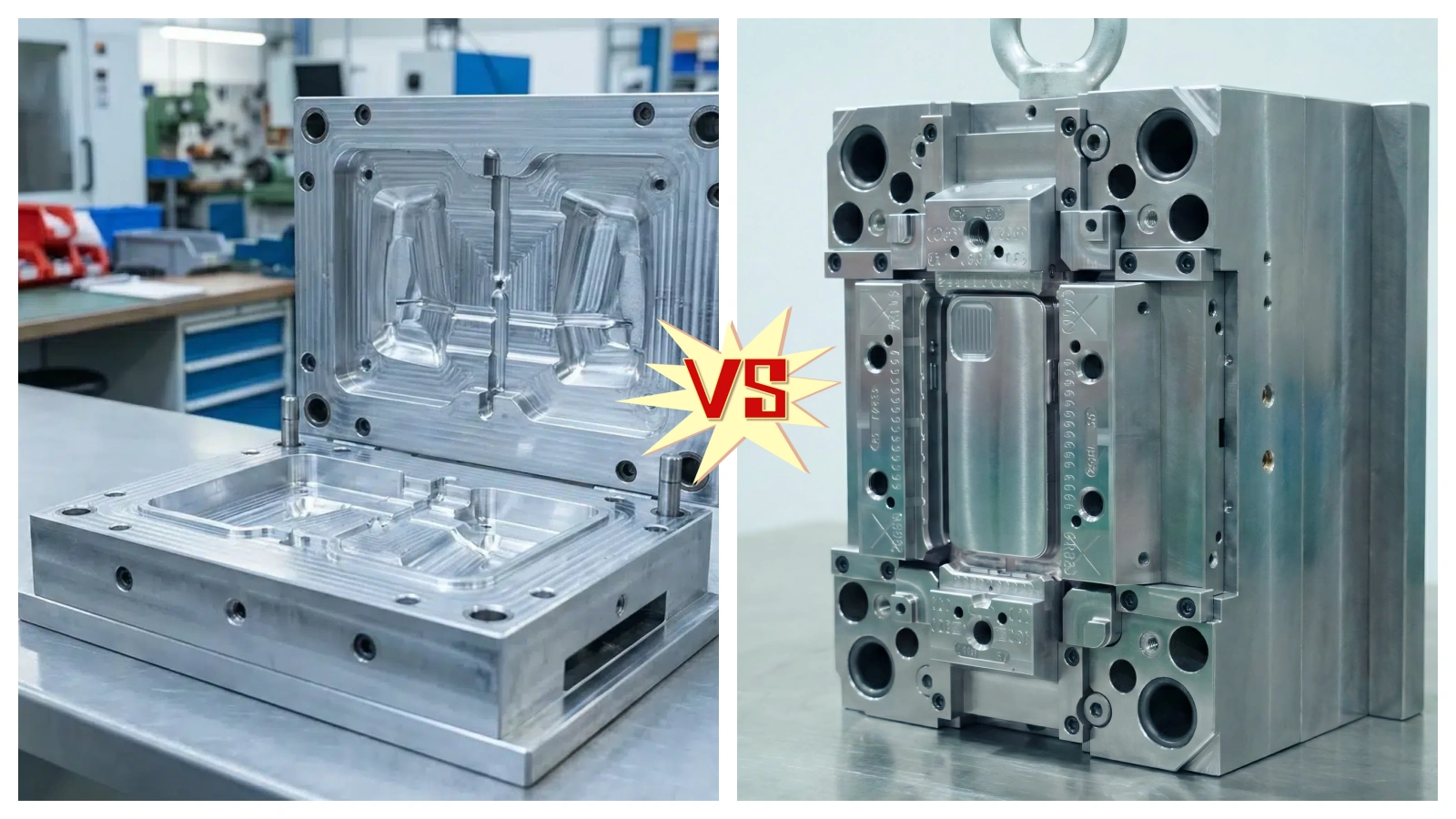

Finding the right manufacturing partner was critical for the project’s success. The brand required a supplier with specialized expertise in precision injection molding and the ability to handle complex mechanical assemblies like heavy-duty metal clips. After a rigorous evaluation of OEM/ODM capabilities, YG was selected as the exclusive partner for its track record in delivering high-tolerance medical accessories to developed markets on a strict production schedule.

| Category | Project Details |

| Industry | Medical Device Accessories |

| Product | Heavy-duty Insulin Pump Case with Metal Clip |

| Services Provided | OEM/ODM Manufacturing & Rapid Prototyping |

| Technology | Precision Injection Molding & Mechanical Assembly |

| Materials | High-impact Durable Plastic & Stainless Steel |

| Surface Treatments | Ergonomic Texture, Matte Finish |

The Challenge: When “Cheap Accessories” Erode Premium Brand Trust

he client’s primary bottleneck was a lack of structural integrity. Their previous supplier’s solution suffered from severe material fatigue, leading to a cycle of product failures:

Clip Stress Fractures: Conventional plastic clips failed under the constant cyclic loading of daily use, snapping when users transitioned from sitting to standing.

Insufficient Impact Mitigation: Existing cases failed to pass the 3-meter drop test, allowing kinetic energy to transfer directly to the sensitive electronics within the pump.

Skyrocketing RMA Costs: Product failures triggered a surge in RMA (Return Merchandise Authorization) claims, reaching 12.5% and threatening both brand loyalty and cash flow.

The Solution: Balancing Slim Profiles with Heavy-Duty Protection

YG’s engineering team re-engineered the product using precision injection molding and advanced polymer science to balance a slim profile with extreme durability.

1. Heavy-Duty Mechanical Clip Assembly

To eliminate the breakage issues common in one-piece plastic designs, we implemented a post-molding mechanical assembly for the belt clip.

The Engineering Logic: Instead of relying on a fragile molded-in plastic hinge, we utilize a heavy-duty metal clip that is precision-assembled onto a reinforced housing. This mechanical fastening approach allows the clip to handle significantly higher tension and torque. By separating the clip assembly from the main chassis molding, we ensure that the high-stress contact points are supported by the metal’s inherent structural memory, preventing the material fatigue that plagues standard plastic alternatives.

2. Reinforced Technology & Energy Dissipation

The “ruggedness” of the case stems from its internal architecture.

The Process: We implemented Reinforced Technology by optimizing the mold with internal ribbing and radius enhancements at high-stress corners. This design directs kinetic energy away from the impact point and dissipates it through the outer perimeter of the shell, preventing screen cracks and internal hardware displacement.

3. Technical Comparison: YG’s Solution vs. Conventional Standards

| Feature | Conventional Market Solutions | YG’s Reinforced Solution | Business Impact |

| Clip Attachment | Integrated plastic mold | High-Strength Mechanical Assembly | Significantly higher pull-strength. |

| Clip Material | Standard ABS or PC Plastic | Heavy-duty Built-in Metal | Eliminates 90% of clip breakage. |

| Durability Standard | Basic 1-meter drop | 3-Meter Drop Test Certified | Protects $3000+ medical devices. |

| Form Factor | Bulky or overly flexible | Slim & Lightweight Profile | Increases user compliance. |

| Material Resistance | Prone to stress cracking | Medical-grade ESCR Polymers | Resists degradation from sweat. |

Real-World User Experience

Imagine the daily routine of an active user—a person managing diabetes while maintaining an on-the-go lifestyle:

When the user wakes up, the Heavy-duty Built-in Metal Clip allows for a secure, one-handed attachment to a belt or waistband. The Comfortable Grip Design ensures that even with damp hands, the device feels secure. During high-intensity activities like jogging or gardening, the audible “snap” of the metal clip provides peace of mind, knowing the expensive medical device is locked in place.

The Results: From Cost Center to Profit Driver

After six months of market deployment, the client achieved remarkable business improvements:

Quality Performance: Complaints regarding structural damage plummeted from 12.5% to less than 0.4%.

Operational Efficiency: While the per-unit cost increased slightly, the Total Cost of Ownership (TCO) dropped significantly as logistics and warranty processing costs were reduced by 70%.

Market Positioning: The product’s retail rating climbed to 4.8 stars on major e-commerce platforms.

Client Testimonial

“Before YG, our accessories were a liability. Their team demonstrated exceptional Design for Manufacturing (DFM) expertise, integrating a heavy-duty metal clip into a slim profile without compromising aesthetics. Since moving our OEM production to YG, our RMA rate has dropped by 95%, securing our reputation in the premium MedTech market.”

— Marcus Weber, VP of Operations, VitalCare Solutions (Germany)

FAQ

Q: Why is the metal clip assembled separately rather than molded into the plastic?

A: Our engineering tests show that mechanical assembly provides superior longevity for medical wearables. By assembling the metal clip into a precision-engineered reinforced slot, we avoid the internal stresses that occur during the cooling phase of insert molding. This ensures the case maintains its Slim Protective profile while the clip provides a much stronger, more reliable “bite” on belts.

Q: How do you ensure the materials won’t degrade when exposed to sweat or cleaning agents?

A: YG utilizes polymers with high Environmental Stress Crack Resistance (ESCR). Our materials are tested against synthetic sebum (skin oils) and 70% isopropyl alcohol to ensure no discoloration or embrittlement occurs over a 3-year lifecycle.

Q: How is the 3-meter drop test performed?

A: We follow a rigorous protocol where the case, weighted with a dummy load, is dropped 26 times from 3 meters onto a hard surface. A “Pass” is only granted if there are zero cracks and the internal load remains fully functional.

Moving Forward: A Partnership Built on Precision and Trust

The success of the insulin pump case project has evolved into a stable, long-term strategic partnership. Based on the significant reduction in RMA rates and positive market feedback, the client has now entrusted YG with the ODM/OEM development of their entire wearable accessory portfolio. This collaboration proves that when engineering precision meets reliable manufacturing, the result is not just a product, but a sustainable competitive advantage.

Why Leading Brands Choose Us

As a specialized provider of OEM/ODM services for plastic mold opening and injection molding, YG offers more than just manufacturing capacity:

Medical-Grade Quality Management: Our facilities are ISO 13485 certified, ensuring that every component we produce adheres to the rigorous quality standards required for medical device accessories.

Engineering-First Approach: We provide deep Design for Manufacturing (DFM) insights to optimize product structures, such as our reinforced mechanical assemblies, before they reach the production line.

Scalable & Reliable Production: From rapid prototyping to high-volume injection molding, we maintain strict tolerance controls and delivery schedules to meet the demands of developed markets in Europe and North America.

Partner with YG for Your Next Project

If your brand is facing high return rates, durability challenges, or is looking to launch a high-performance protective solution, partner with a manufacturer that understands the stakes. We are ready to help you transform your technical requirements into market-leading products.

Contact us today to discuss your custom project or to request a sample of our high-durability solutions. Visit our website at https://ygcases.com/ to learn more about our capabilities.