Selecting the right tooling system is a high-stakes decision that directly impacts your bottom line. Most manufacturers agree that while efficiency is king, balancing upfront mold costs with long-term production waste remains a constant struggle.

This guide will demystify cold runner injection molding, moving beyond basic definitions to provide actionable cost-saving strategies based on decades of shop-floor experience.

What is Cold Runner Injection Molding?

Table of Contents

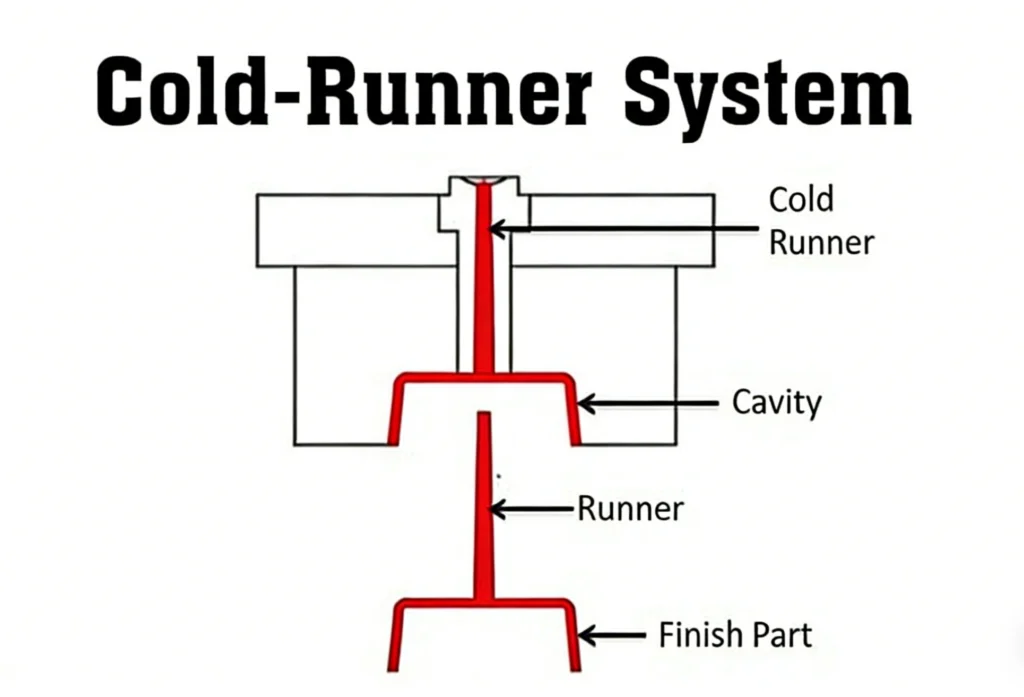

ToggleCold runner injection molding refers to a mold configuration where the delivery channels (the runners) are unheated and integrated into the mold plates. In this process, the molten polymer travels from the machine nozzle through the sprue, runners, and gates into the mold cavities.

Because the entire mold is maintained at a temperature below the polymer’s transition point, both the final part and the plastic remaining in the runner system solidify simultaneously.

The Core Components

To control the flow dynamics, three distinct functional zones must be precisely managed:

The Sprue: The primary channel connecting the machine nozzle to the runner system. It is tapered to facilitate easy ejection.

The Runner: The distribution network that directs the polymer melt to multiple cavities. Its diameter must be calculated to balance pressure drop against cooling time.

The Gate: The restricted entry point into the cavity. It controls the shear rate of the material and determines the ease of part separation.

Upon completion of the cooling phase, the mold opens at the parting line. An ejection system physically pushes the solidified “runner tree” and the parts out of the mold. The runner is then separated from the part through mechanical shearing or manual trimming.

Types of Cold Runner Molds: Two-Plate vs. Three-Plate Systems

In the world of cold runner injection molding, the architecture of your mold determines your labor costs and production speed.

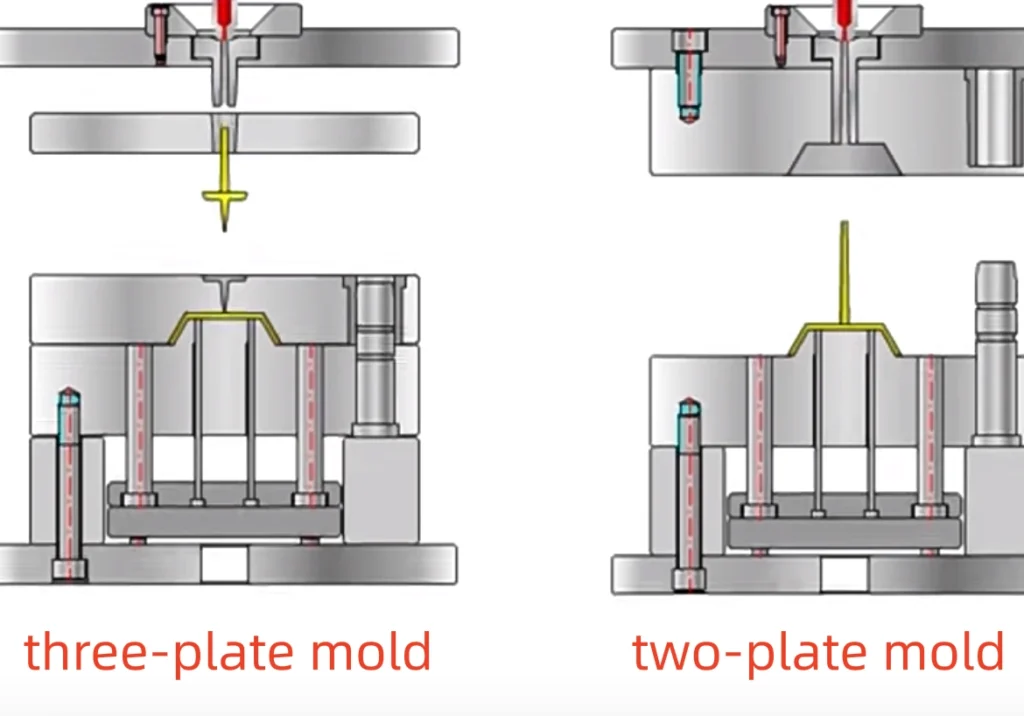

The Two-Plate Mold: Simple and Rugged

The two-plate mold is the most common configuration in the industry. It consists of one opening (parting line). Both the part and the runner system are ejected together as a single unit.

Best for: Large parts, simple geometries, and low-volume production.

The Catch: You must manually trim the runner or use a secondary degating operation.

The Three-Plate Mold: The Automation Standard

A three-plate mold adds an extra plate, creating two separate openings when the mold cycles. This allows the runner system to be stripped and ejected independently of the parts.

Best for: High-volume projects and multi-cavity molds where manual trimming is too expensive.

The Catch: The mold is more complex to design and maintain.

Cost Analysis of Cold Runner Injection Molding

Many engineers assume “cold” means “cheap.” That is a half-truth. While the initial investment is lower, the long-term cost per part can be higher due to material waste.

The TCO (Total Cost of Ownership) Formula

To make an informed decision, don’t just look at the mold price. Use this formula:

Design Secrets: How to Build a High-Performing Cold Runner Mold

In cold-runner injection molding, the runner design is not arbitrary; it must follow strict thermal and fluid-dynamic logic to ensure part quality.

Runner Geometry: Surface Area vs. Pressure

The goal is to keep the plastic molten until the cavity is full, then have it solidify quickly.

Full Round Runners are preferred because they have the lowest surface-area-to-volume ratio. This minimizes heat loss to the mold plates, allowing the plastic to flow further with less injection pressure.

Trapezoidal Runners are used when machining costs must be reduced, as they only require milling on one side of the mold plate.

The Cold Slug Well: Preventing Structural Defects

During the injection pause, a small amount of plastic at the nozzle tip cools and solidifies. If this “cold slug” enters the cavity, it causes “cold shots” or structural weak spots.

The Solution: Design an extension at every runner intersection. These “wells” trap the solidified tip, ensuring only the hot, uniform melt enters the gate.

The 1.5x Rule: Balancing Packing and Cooling

The runner diameter should be 1.5 times the thickness of the part’s thickest wall.

The Reason: The runner must stay molten longer than the part. This allows the machine to continue “packing” material into the cavity to compensate for shrinkage as the part cools. If the runner freezes first, the part will develop sink marks or voids.

Advantages and Disadvantages of Cold Runner Systems

Understanding the trade-offs is essential to the long-term viability of a project. Cold runner injection molding offers distinct mechanical benefits but presents clear operational challenges.

Advantages of Cold Runner Systems

Reduced Initial Investment: Lower capital expenditure (CAPEX) since no expensive manifolds or electrical controllers are required.

Material Integrity: Ideal for heat-sensitive polymers (e.g., PVC, POM) as it prevents material residence time issues and thermal degradation.

Ease of Maintenance: Simple mechanical structures mean less downtime for cleaning and no risk of heater failure or nozzle clogs.

Fast Color Changes: Since the entire system is purged every cycle, switching colors is significantly faster than in hot runner systems.

Disadvantages of Cold Runner Systems

Material Waste: The solidified runner becomes scrap. Even with recycling, the “regrind” process adds energy and labor costs.

Extended Cycle Times: The runner is typically the thickest part of the shot. The machine must wait for the runner to solidify before ejecting, which increases the overall cycle time.

Labor Intensity: Two-plate systems often require manual degating or secondary trimming processes.

Is Cold Runner Right for Your Project?

Determining the ROI of cold runner injection molding requires a precise look at production scale and material costs. While a hot runner might save 2 seconds per cycle, those savings are irrelevant if the total production run is too short to amortize the high mold cost.

For projects involving less than 100,000 units, the lower fabrication cost of a cold runner mold almost always provides a faster break-even point. However, once production exceeds 500,000 units, the cumulative cost of material scrap and the 10-15% increase in cycle time typically justify the transition to hot runner technology.

| Project Factor | Choose Cold Runner If… | Choose Hot Runner If… |

| Production Volume | < 100,000 parts | > 500,000 parts |

| Initial Investment | Lower CAPEX is required. | High automation budget available. |

| Material Cost | Using low-cost resins (PP, PE). | Using expensive resins (PEEK, PSU). |

| Lead Time | 4–6 Weeks (Standard build). | 8–12 Weeks (Complex manifold). |

FAQ

Q: What is the main difference between cold runner and hot runner systems?

A: In cold runner injection molding, the plastic in the distribution channels solidifies with the part and is ejected every cycle. In a hot runner system, the plastic stays molten in a heated manifold.

Q: Can cold runner scrap be reused?

A: Yes. Most thermoplastics can be granulated into “regrind” and mixed with virgin resin (typically at a 20% ratio) without losing mechanical properties.

Q: Does cold runner injection molding increase cycle time? A: Generally, yes. The cooling time is often dictated by the runner thickness. Since runners must be thick enough to pack the part, they take longer to cool than the parts themselves.

Q: Is it suitable for medical devices?

A: Absolutely. It is ideal for cleanrooms because it avoids material degradation and “black specks” that can occur in heated manifolds.

Conclusion

Success in cold runner injection molding requires more than just a mold—it requires a strategic approach to design and production economics. At YG, we specialize in high-precision ODM/OEM plastic injection molding, helping global brands optimize their tooling for maximum ROI. Whether you are launching a new consumer electronic device or a complex medical housing, our team ensures your project meets international quality standards while staying under budget.

Ready to optimize your next project? Contact YG for a custom mold quote today.

.webp)