Introduction

Table of Contents

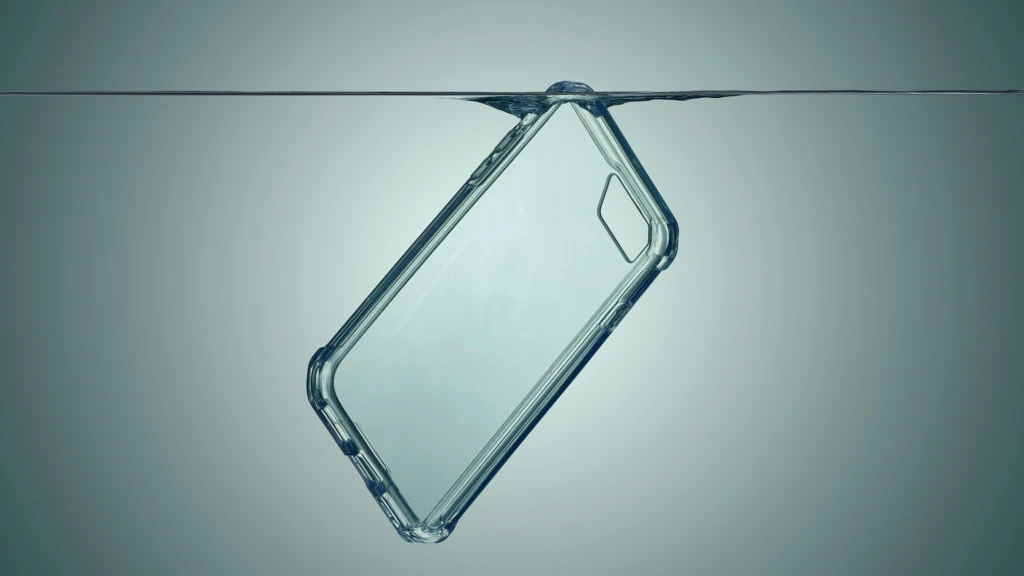

ToggleOutdoor brands demand accessories that survive extreme conditions. When Alpine Outdoor Gear, a leader in European adventure equipment, faced 8.7% return rates due to faulty waterproof cases, they partnered with YG. As a certified waterproof phone case manufacturer, we delivered IP68-certified solutions, slashing returns to 0.9% and boosting client profitability.

Client Background & Challenges

1. Industry Positioning

Alpine Outdoor Gear specializes in rugged gear for hiking and water sports, but it struggles to source durable phone cases. Their existing supplier’s IP65-rated cases fail submersion tests, damaging customer trust.

2. Critical Pain Points

- Weak Waterproofing: IP65 cases leaked after 30 minutes of exposure, causing 72% of returns.

- High Costs: Secondary treatments added 15% production costs and delayed shipments by 20 days.

- Customization Limits: Competitors couldn’t embed brand logos without compromising seals.

YG’s Solutions: Engineering Excellence for Waterproof Cases

1. Triple-Layer Waterproof Technology

YG’s IP68-certified cases combine three innovations:

- Ultrasonic Welding: Seamless edge bonding prevents leaks.

- Nano-Coating: Repels splashes while maintaining wireless charging.

- Precision Molds: <0.01mm tolerance perfectly fits all models.

2. Fast-Track Customization

YG’s 30+ engineers delivered a logo-embedded prototype in 7 days (vs. 15-day industry average). MUD mold tech cut tooling costs by 30%, enabling small batches (MOQ 500).

3. Cost-Effective Production

Optimized materials and molding cycles reduced Alpine’s per-unit costs by 22% versus EU suppliers. Bulk orders are shipped in 18 days, beating the 45-day market average.

Quality Assurance: Why Brands Trust YG

1. Rigorous Testing

Every batch undergoes:

- 72-hour submersion tests at 1m depth.

- 10-drop tests on concrete from 1.2m.

- 100+ annual third-party audits.

2. Certified Manufacturing

YG’s ISO 9001/14001 and GRS 4.0 certifications ensure eco-conscious production. A 53-member QC team maintains <0.3% defect rates.

Results: Transforming Supply Chain Efficiency

- Returns Reduced: 8.7% → 0.9% post-YG partnership.

- Faster Time-to-Market: 18-day delivery accelerated launches.

- Revenue Growth: Client’s accessory sales grew 170% YoY.

Client Testimonial

“YG achieved IP68 certification and integrated our custom grip design—something we thought impossible.”

— Alpine Outdoor Gear Procurement Director

Partner with a Leading Waterproof Phone Case Manufacturer

Schedule Free Consultation: Let YG solve your waterproofing challenges.