As a tablet cover factory with 130+ injection machines, YG empowers tech brands to solve all kinds of production problems. The following case can show what we’re capable of: We helped a distributor speed up their delivery by 28% and got their repeat order rate up to 65%.

1. Client Profile: High requirements

Table of Contents

ToggleOur wholesalers need:

- Customized Protective Cases for Tablets with brand logos

- Best tablet case material that meets strict certification

- Reliable bulk orders during seasonal sales peaks

2. How YG addresses the challenges

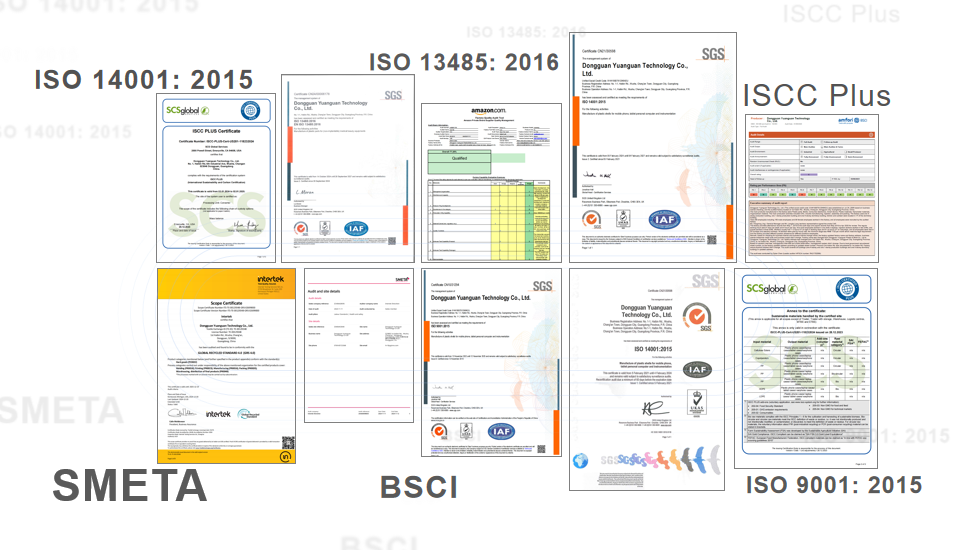

Challenge 1: The strict requirements for certification

Pain Point: Customers face rejection due to incomplete documents.

YG’s Certified Advantage:

- Production facilities that have obtained an ISO 9001 & BSCI certification

- Obtained SMETA ethical compliance audit certification factory

- With recycled material shell of GRS 4.0 certification

- Have a REACH chemical safety compliance report

Main achievements:

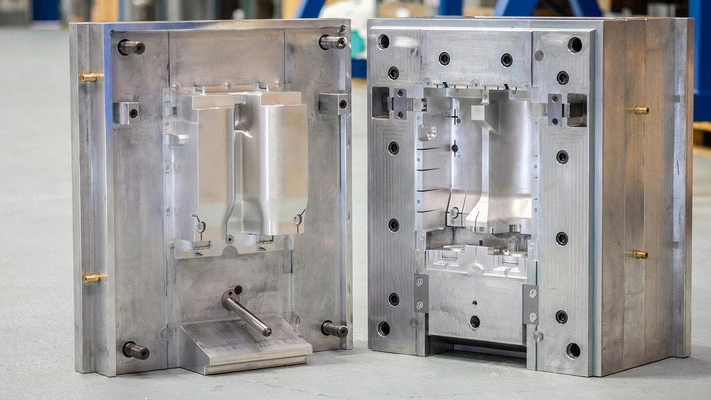

Challenge 2: High cost of customized orders

Pain Point: The traditional mold cost makes small batches unprofitable.

YG’s MUD Mold Breakthrough:

- 80+ patented technologies, Realize rapid prototyping

- 40+ Senior mold making mechanic reduces mold design time by 50%

- MOQ 500 pcs can be achieved through a modular mold system

- Urgent projects can achieve a prototype turnaround time of 3 days

Challenge 3: Delivery time is difficult to guarantee

Pain Point: Excessive congestion at ports can lead to delays of goods during peak seasons

YG’s logistics plan:

- Localized warehousing services for the Los Angeles warehouse in the United States

- Stable 3PL partnership ensures delivery to the last mile

- Daily output of 300k units can prevent overstocking

- Standard delivery time of 35 days (compared with the industry average of 45 days)

Challenge 4: Demand for sustainable materials

Pain Point: Buyers need environmentally friendly options, but they lack reliable suppliers.

YG’s Solutions:

- We maintain long-term cooperative partnerships with many material suppliers

- GRS-certified recycled plastics for Protective Tablets Case

- Plant-based TPU alternatives to petroleum products

- Custom material blends (e.g., anti-microbial additives)

Verifiable Impact:

3. Data-Driven Results

- Average lead time: 35 days (28% faster than competitors)

- Peak season capacity: 1.2M units/month

- Return client rate: 65% (2024 Q1-Q3)

5. Client Testimonials

“YG’s MUD mold technology let us test 12 custom tablet onn case designs cost-effectively.” – EuroTech Distributors

“Their Los Angeles warehouse ensured Black Friday stock despite shipping crises.” – PrimeGadgets USA

Ready to Build Your Tablet Case Business?

YG, an ISO/BSCI-certified tablet case manufacturer, empowers global partners with:

✓ 72-hour prototype service using patented MUD mold technology

✓ 100% compliance guarantee for US/EU markets

✓ Dedicated Los Angeles warehouse for faster North America delivery

.webp)