Introduction: Surging Demand for Ethical Leather Cases

Table of Contents

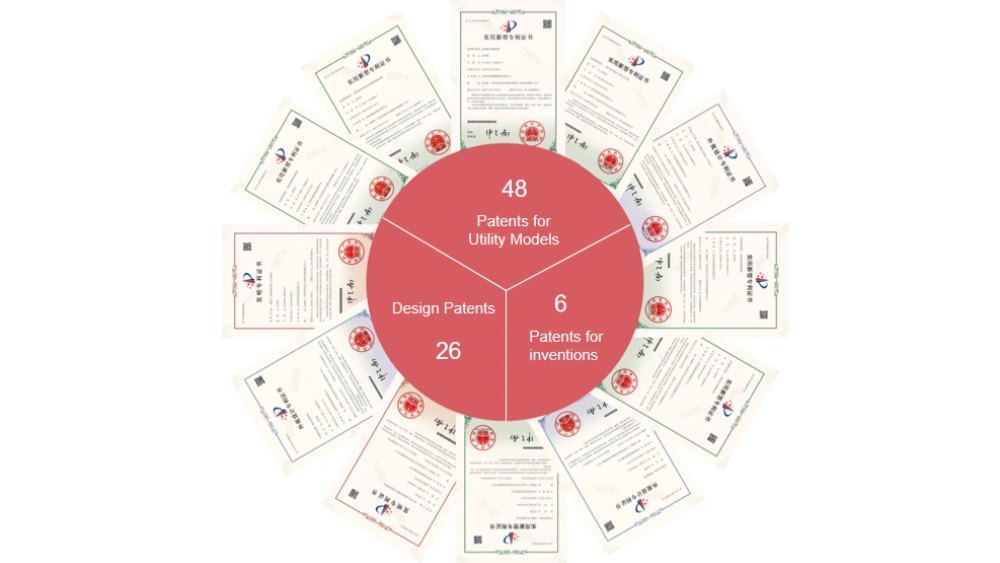

ToggleOver 68% of US/EU consumers now prioritize custom leather phone cases with sustainability credentials (Textile Exchange 2024). As a leather phone case manufacturer serving global brands, YG combines GR-certified materials with patented IM-3D-E technology to deliver luxury, compliance, and agility.

Challenge 1: Material Durability & Supply Chain Transparency

Industry Pain Points

- 42% of leather cases fail abrasion tests within 6 months (SGS Lab Report 2024)

- 73% of buyers struggle to verify eco-claims from overseas suppliers

YG’s Solution

Challenge 2: Custom Design Implementation

Operational Bottlenecks

- 45-day average development cycle for a leather phone case with a card holder

- 16.7% logo peeling rate vs YG’s <3% (internal stress tests)

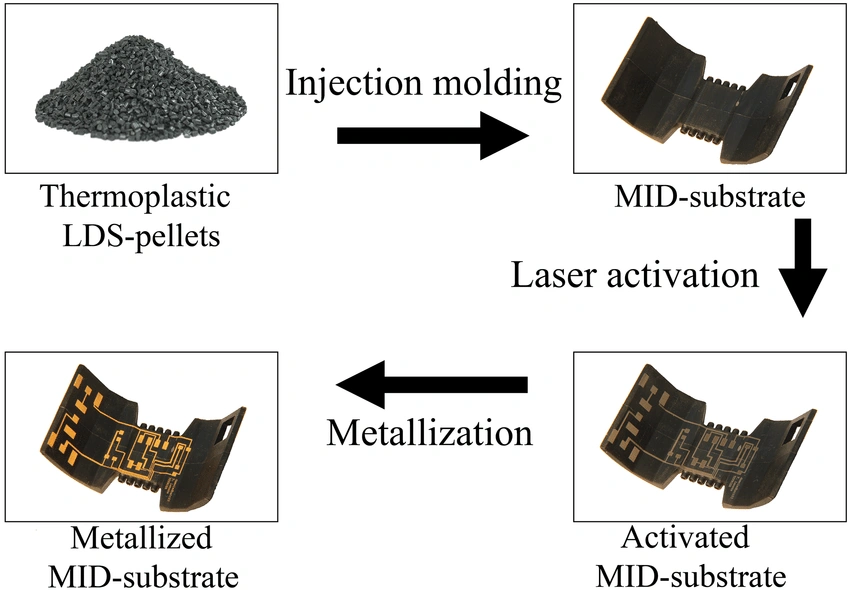

YG’s Tech Edge

Challenge 3: Compliance & Certification

Regulatory Updates

- EU SCIP database added 63 restricted substances (2023 Q4)

- 380/industryavgtestingcostvsYG’s380/industryavgtestingcostvsYG’s85/batch

YG’s Protocols

Client Success: BioTricity Case Study

Before YG Partnership

After Implementing YG Solutions

Ready to Launch Your Premium Leather Case Line? Contact OEM Team: MOQ 500 | 7-Day Samples | 100% REACH Compliance