Introduction

Table of Contents

ToggleSmartphone brands are facing a severe challenge: consumers need a crystal-clear appearance and military-grade protection. The traditional clear case is prone to cracking or yellowing, resulting in a 37% higher brand return rate.

As a reliable phone case manufacturer, YG has designed a breakthrough: a full-frame shockproof phone case. This innovation, which combines 92% transparency and 360° drop protection, was proven in a 1.5-meter concrete test.

Challenge: Fragile Clear Phone Cases Damage the Brand

A European consumer electronics brand has launched smooth and transparent phone cases. Sales soared – until reviews hit:

It looks wonderful, but the first drop broke!

“The scratch on the phone has returned to the starting point…”

This is the harsh reality that many brands are facing. clear phone case failed at a critical moment:

- Only the protection of the corners exposes the edges

- A few weeks later, it turned yellow, spoiling the appearance

- One third of the customers requested a refund

As an experienced China phone case manufacturer, we have proposed a solution.

YG’s Solution: Material blending + All-inclusive anti-drop strips

YG’s solution originated from a simple fact: true protection requires 360° defense.

Here’s how we rebuilt shockproof phone cases from scratch:

We know that PC is a kind of hard phone case material. It is hard, lightweight, and not easy to deform. It has excellent optical transparency and can clearly display the original color and design of the mobile phone. It is the preferred material for transparent mobile phone cases. However, it is not shockproof and is prone to cracking when dropped from a height.

TPU is different. It is a soft elastomer with a soft material that can be bent. It can effectively buffer the impact of drops, distribute pressure, reduce the risk of damage to mobile phones, has good elasticity, is easy to disassemble and install, and has excellent anti-drop performance.

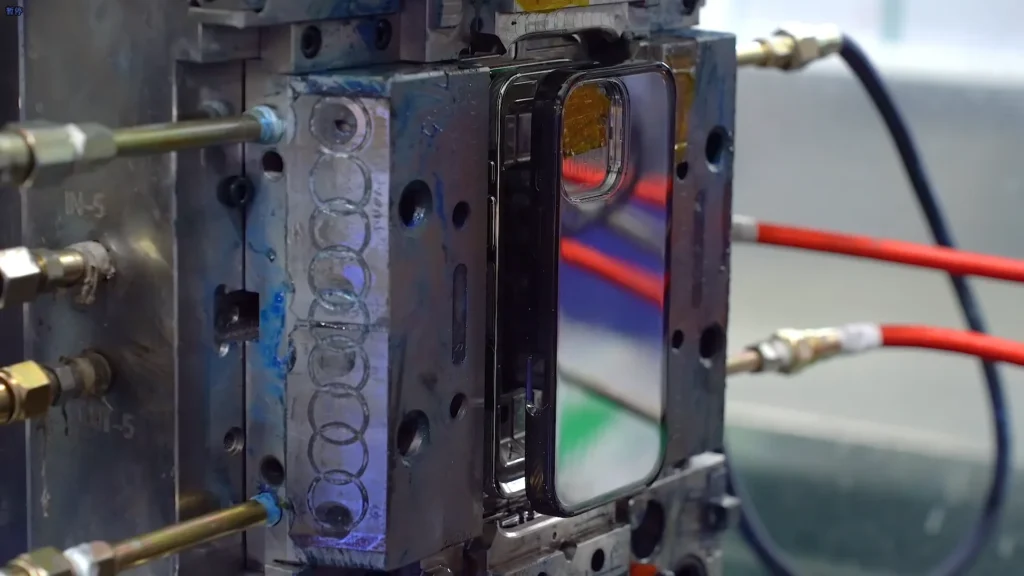

Therefore, YG utilized the overmolding technology to effectively combine these two materials. The combination of a PC back panel and a TPU frame enables the phone case to have both high transparency and basic shock and Drop Protection.

However, such protection is not enough. We need more rigorous protection. YG’s solution is to inject anti-drop strips around the interior of the phone case (except for the buttons) based on a basic transparent protective phone case. This is the best protective case for cell phone

Rigorous Validation: Military-Grade Assurance

Drop Tests You Can Trust

- 1.5m multi-angle drops on concrete: 100% pass rate.

- Industry-leading metrics:

- 6x stricter than MIL-STD-810G standards.

- 200+ cycles per design in YG’s lab.

Quality Certifications

- ISO 9001 production controls.

- REACH/FDA-compliant materials—safe for global markets

Agile Manufacturing: Speed to Market

Streamlined Workflow

YG offers a one-stop solution from design to packaging.

1. Design and prototype:

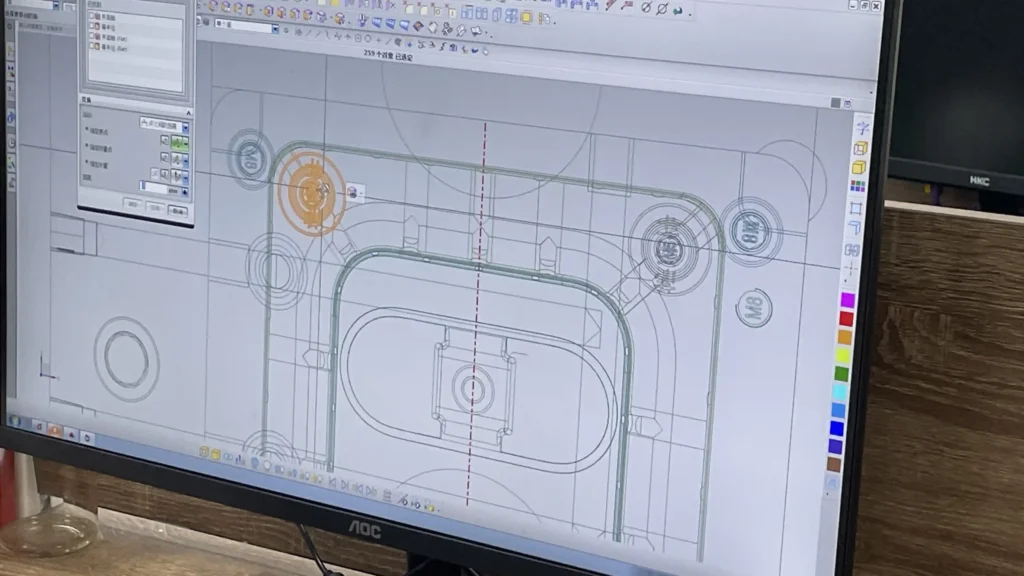

Turning concepts into reality requires rigorous engineering design. In the early stage, our designer team combines aesthetic and manufacturing requirements to generate CAD design drafts and create prototypes, helping clients evaluate the size, appearance, and texture of the design and make improvements. This process can quickly iterate and confirm the final form of the product.

2. Mold design and manufacturing:

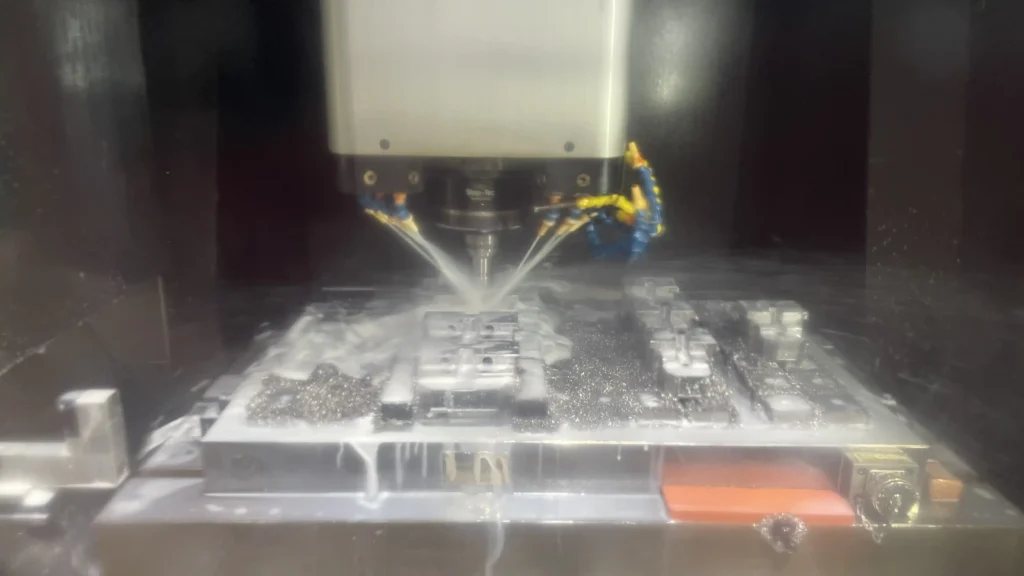

To achieve batch production, we design and manufacture molds to ensure the smooth production of mobile phone cases. We use the latest CAD software and advanced CNC processing equipment, and electrical discharge machines to produce molds with precise dimensions and high-quality surface quality.

3. Injection molding:

During this process, we first generate the PC backsheet through injection molding, then re-place it into the injection molding machine to cover the TPU frame, and finally use MUD technology to quickly replace the mold core and injection mold the anti-drop strip.

4. Quality assurance:

Quality management runs through the entire production process. Our quality control team will conduct strict inspections and tests. We use advanced testing equipment and methods, including appearance, precision, and drop resistance tests, to ensure that each phone case meets high-standard quality requirements.

5. Packaging:

YG offers customized packaging services. Our packaging design team will create designs based on your ideas and produce them through our packaging supply chain factory. We will provide inspection reports to help you save time and costs.

Results

- Returns reduced by 48% in 3 months.

- Amazon rating jumped to 4.8 stars (“Finally, clear AND tough!”).

“YG is not just a vendor – they’re strategic partners. Their team solved our clear protective phone case crisis with overmolding tech, cutting returns by 48%. Communication? 10/10.”

.webp)