Finding the best eco-friendly phone case manufacturers in 2026 is no longer just about avoiding plastic; it’s about surviving a complex market of shifting regulations and material durability. Many brands settle for suppliers whose “compostable” products yellow in weeks or fail basic drop tests, leading to costly returns and a damaged reputation. You shouldn’t have to choose between your ESG goals and your product’s quality.

This guide cuts through the greenwashing to reveal the top-tier manufacturers leading the circular economy today. We’ve analyzed their tech, transparency, and lead times to help you scale your sustainable brand with confidence.

The 2026 Sustainable Shift: Why Your Choice of Manufacturer Matters Now

Table of Contents

ToggleIn 2026, “sustainability” is a legal and operational requirement, not a marketing buzzword. The global market has moved from voluntary “green” initiatives to mandatory compliance. For brand owners, the stakes are higher than ever.

The Regulatory Reality: Compliance is Non-Negotiable

The biggest change this year is the full implementation of the EU’s Ecodesign for Sustainable Products Regulation (ESPR). You can’t just claim a product is “green” anymore; you have to prove it.

The best eco-friendly phone case manufacturers have transitioned from being simple suppliers to data partners. They now provide a Digital Product Passport (DPP) for every batch, which includes:

Material Origin: Verified recycled content percentages.

Carbon Footprint: Measured from raw material extraction to your warehouse door.

Circular Potential: Proven recyclability or compostability paths.

Before signing a contract, ask for a sample of their Life Cycle Assessment (LCA) report. If they can’t provide data-backed environmental impact scores, they are a liability to your brand.

Spotting the “Green Gap”: Marketing vs. Reality

Many manufacturers offer “wheat straw” or “cornstarch” cases that fail under real-world conditions. In 2026, consumers are hyper-aware of greenwashing. If your cases crumble too early or never degrade in a backyard compost, your brand’s reputation takes the hit.

| Feature | Budget “Eco” Factory | 2026 Compliance Leader |

| Certifications | “Eco-friendly” (Self-claimed) | GRS, RCS, and FSC certified |

| Durability | Yellows/cracks within 3 months | 2-year UV resistance & drop-tested |

| Transparency | Vague “bio-plastic” labels | Full material breakdown (e.g., 70% PBAT / 30% PLA) |

| Waste Management | Linear production | Closed-loop (Recycles production scrap) |

Top-Rated Eco-Friendly Phone Case Manufacturers to Watch in 2026

Navigating the crowded supplier market requires a sharp eye for ethics and engineering. The best eco-friendly phone case manufacturers offer a transparent, verified path to sustainability.

| Category | Recommended Partner | Key Innovation | Best For |

| B2B / OEM Powerhouse | YG Cases (YG) | Precision Tooling for Bio-polymers | Brands needing custom, high-volume production. |

| Material Innovation | Agood Company | Climate-positive plant-based loops | Sustainable startups prioritizing circularity. |

| Recycled Specialist | Nimble | Certified Recycled Ocean Plastics | Tech brands focused on “Post-Consumer” stories. |

| Compostable Leader | Pela Case | Flaxstic® (Flax Shive & Biopolymers) | Niche eco-brands seeking 100% compostability. |

YG Cases: The Precision Engineering Expert

YG has redefined eco-friendly phone case manufacturing by solving the “durability gap.” They use advanced precision rapid tooling techniques specifically designed for bio-plastics. This ensures your cases don’t just feel green—they last as long as the phone itself.

Standout Feature: High-precision tooling that supports complex, thin-wall designs.

Why it matters: Most eco-materials are difficult to mold; YG makes it seamless.

Agood Company: The Circularity Champion

Based in Europe, Agood Company leads with their agood loop™ system. They take back old cases to grind them into new ones, offering the ultimate “closed-loop” model for 2026.

Standout Feature: World’s first climate-positive phone case.

Why it matters: It provides a ready-made end-of-life solution for your customers.

Nimble: The Certified Recycled Authority

Nimble focuses heavily on RCS (Recycled Claim Standard) materials. They excel at turning old CDs and ocean-bound plastics into premium, protective covers.

Standout Feature: B-Corp certified with ultra-transparent material sourcing.

Pela Case: The Pioneer of Compostable Innovation

Pela is the original disruptor in this space. While many focus on recycled plastics, Pela remains the gold standard for 100% compostable solutions. Their proprietary material, Flaxstic®, is a unique blend of flax shive and plant-based biopolymers.

Standout Feature: World’s first “Home Compostable” certification.

Why it matters: It’s the perfect “Zero-Waste” story for brands targeting the most eco-conscious segments.

Material Science: Decoding the “Eco-Friendly” Label

In 2026, look past the marketing. You need to understand the molecular reality of what you are buying. The best eco-friendly phone case manufacturers pick materials based on how they survive the real world while minimizing harm.

The 2026 Material Matrix

Not all sustainable materials are created equal. Use this table to decode the labels your suppliers send you:

| Material Type | Core Composition | Durability | Best For… |

| Recycled TPU (rTPU) | Post-consumer plastic waste. | High. Mimics virgin plastic. | Drop-proof, heavy-duty protection. |

| Bio-based Polymers | Derived from corn or sugarcane. | Medium. Prone to yellowing. | Brands focused on renewable resources. |

| Compostable Blends | Usually PLA and PBAT. | Moderate. Softer texture. | 100% zero-waste market positioning. |

| Composite “Waste” | Wheat straw or coffee grounds. | Variable. Texture is the seller. | Unique aesthetics and storytelling. |

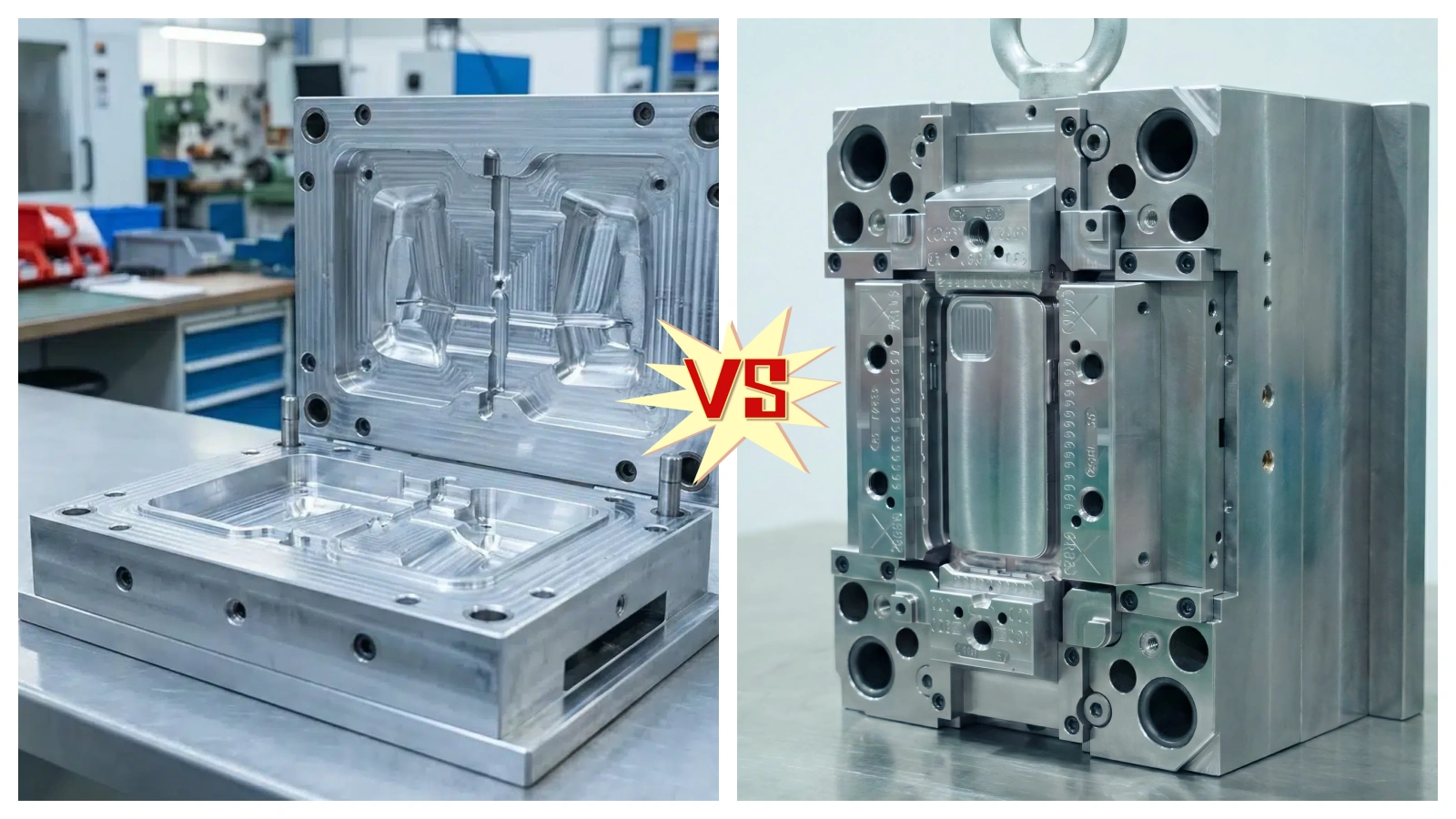

The Technical Challenge: Why Molding Matters

Bio-plastics behave differently than traditional oil-based plastics in the mold. Most eco-friendly phone case manufacturers struggle with “Material Shrinkage,” which causes warping or weak spots near the camera ring and charging ports.

At YG, we don’t rely on guesswork. We solve this through Advanced Moldflow Analysis. Before cutting steel, our engineers simulate the resin’s behavior to optimize gate placement and cooling channels. By combining this with Scientific Injection Molding (SIM) protocols, we maintain strict dimensional stability, ensuring your eco-cases fit the latest iPhone models perfectly without the common “loose edges” seen in lower-quality eco-products.

Ask your manufacturer if they perform Pre-molding Flow Simulations. If they can’t show you a flow analysis report for bio-materials, your defect rate will likely be high due to unpredictable shrinkage.

How to Vet a Sustainable Manufacturer: A 5-Point Checklist

Choosing a partner is the most critical decision for your brand. In 2026, a “green” website isn’t enough. You have to audit the factory floor.

Verify Certifications in Real-Time: Don’t just accept a PDF. Ask for the factory’s GRS (Global Recycled Standard) license number and check it on the Textile Exchange database.

Audit the Energy Loop: A sustainable product made in a coal-powered factory is a contradiction. Does the factory use solar arrays or a Closed-Loop Water System?

Evaluate Tooling Precision: Ask to see their Molding Temperature Control (MTC) logs. The best eco-friendly phone case manufacturers use high-precision tooling to prevent waste from defects.

Demand Traceability: Provides a Digital Product Passport (DPP) for raw materials. If they won’t name the source, avoid them.

Run the Durability Test: Request a 10-Foot Drop Test Report. If the case fails, the carbon footprint of a broken $1,000 iPhone is far worse than any plastic waste.

The Bottom Line: Costs, MOQs, and Logistics

The “green premium” is real. To build a profitable brand, you must balance environmental goals with your budget.

The Cost Reality

In 2026, sustainable materials still carry a price premium of 20% to 50%. This reflects higher R&D costs and certification fees.

Expert Advice: Don’t just look at the Unit Price. Calculate your Total Cost of Ownership (TCO):

$$TCO = (Unit\ Cost \times Quantity) + Tooling + Compliance\ Fees + Carbon\ Offset\ Shipping$$

Mastering the MOQ

The best eco-friendly phone case manufacturers often have higher MOQs (1,000–3,000 units) because bio-resins require a full machine purge. To lower your MOQs:

Standardize Your Base: Use the same material across all phone models.

Split Shipments: Produce a large run to lower the price, but ship in smaller batches.

Material Sharing: Ask whether the factory already runs a specific eco-material for another brand to “piggyback” on its production line.

FAQ

Q1: Are 100% compostable cases durable enough for drop protection? Pure compostable materials are often brittle. In 2026, the industry uses PBAT-blended composites for flexibility. Look for internal “honeycomb” structures to add strength without non-recyclable bulk.

Q2: How can I verify a manufacturer’s GRS certificate? Ask for the Scope Certificate (SC) and the Transaction Certificate (TC). Check the license number on the official GRS database.

Q3: What is the lead time for custom eco-friendly cases? Eco-materials have longer supply chains. Expect 8–10 weeks for a custom run, compared to 6 weeks for traditional plastics.

Q4: Do eco-friendly cases support MagSafe? Yes, but you must specify N52 Recycled Neodymium Magnets. These are recovered from old electronics and offer the same strength as virgin magnets.

Q5: Can I get a “premium leather” feel sustainably? Yes. Choose Bio-Polyurethane (Bio-PU) made from apple skin or cactus. It offers a luxury hand-feel with a 40% lower carbon footprint.

Conclution

In 2026, the best eco-friendly phone case manufacturers are your compliance and R&D partners. By choosing a partner that prioritizes precision tooling and verified materials, you aren’t just protecting a phone—you are protecting your brand’s future.

Ready to start? If you need precision tooling and GRS-certified production, contact the engineering team at YG Cases today. Let’s build a product that leads the circular economy.