VR/AR Manufacturer

As a professional manufacturer of VR/AR injection molded structural components, YG is committed to providing wholesalers and purchasers with a one-stop solution for VR/AR structural components. We have extensive experience and a professional team that can provide diversified customized services, including structural design, material selection, and brand customization. Contact us now to start a collaboration and explore the infinite business opportunities of VR/AR together!

VR/AR Suppliers In China

VR/AR is an innovative technology that provides immersive and interactive experiences by simulating virtual environments or overlaying digital information onto the real world.

YG’s VR/AR injection-molded structural components stand out with their exceptional features and high-quality design. Our products are made with high-quality materials to ensure durability and provide reliable protection, while also delivering a comfortable wearing experience.

| Material | Si/PC/TPU/ABS |

| MOQ | 1000 Pcs |

| Hardness | / |

| Min. Thickness & Weight | 1.0mm/100g |

| Design | Industrial Design, Mechanical Design, Electronic Design, DFM, etc. |

| Packaging & Brand Customization | Acceptable |

| Process | Injection Molding |

| Mold Making Time | 2-5 Weeks |

| Sample Time | 1-3 Days |

| Delivery Time | 20-50 Days |

| Certifications | ISO9001, ISO14001, Reach, RoHS, BSCI, SMETA, GRS 4.0, etc. |

Different Types of VR/AR

Features of YG VR/AR

YG’s VR/AR injection-molded structural components are characterized by high precision manufacturing, durability, reliability, and lightweight comfort. With extensive experience, high-quality materials, and customized services, YG stands out in the industry, committed to providing perfect solutions for wholesalers and procurement experts seeking high-quality products.

- High precision manufacturing

- durability, reliability

- lightweight comfort

- fine processing

- high-quality materials

- customized services

Ready To Elevate Your Brand?

Partner with YG, your trusted VR/AR supplier, for innovative solutions. Contact us today to discuss how we can bring your vision to life with our customized VR/AR offerings.

Factory Customization In YG

YG factory offers extensive customization options for VR/AR, allowing you to tailor products to meet specific market demands. From bespoke designs and colors to specialized materials and features, our flexibility ensures that you can differentiate your brand and deliver exceptional value to your customers.

Design

We provide a wide range of customization options, including colors, patterns, logos, and packaging. Create unique VR/AR that resonate with your brand identity.

Materials

Choose from high-quality materials such as TPU, PC, and Si. We ensure all materials meet industry standards and provide relevant certifications.

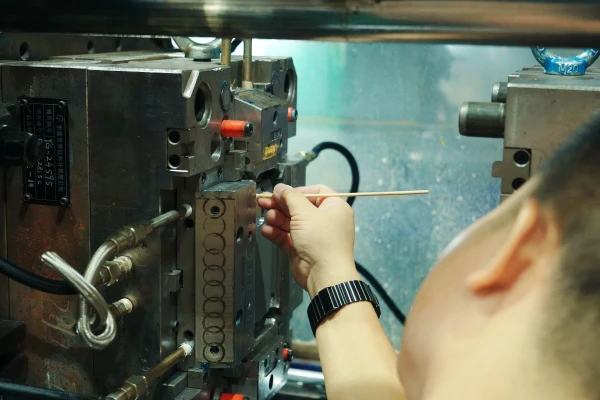

Injection Mold

20+ mold designers and 40+ engineers work closely with you to create custom molds that meet your specifications and improve accuracy of VR/AR.

Low Volume Production

We support small batch customization, allowing you to test new designs or cater to niche markets without the need for large initial orders. Help you manage inventory efficiently

Production Abilities

Choosing a reliable VR/AR manufacturer is essential to ensure product quality, on-time delivery and meeting market demand. YG has strong production capacity and can flexibly meet large and small batch order requirements to ensure rapid response to market changes.

Production Capacity

YG has more than 120 injection molding machines, producing 300,000 VR/AR and 30,000 sets of parts per day, supported by more than 80 mold engineers and more than 100 developers to ensure efficient logistics and on-time delivery.

Mold Making

YG strictly follows ISO standards, 53 quality managers supervise IQC, IPQC, FQC and OQC, equipped with advanced equipment, defect rate is lower than the industry average, and detailed reports and sample traceability are provided.

Technology

We use overmolding and IM-3D-E technology to achieve multi-material bonding and electronic integration, thermal transfer and IMD technology to provide waterproof, anti-fingerprint, antibacterial properties, and hold 77 patents.

Quality Control

YG has passed ISO, BSCI, SMETA, Reach and GRS 4.0 certifications, and conducts more than 100 third-party tests each year to ensure that the VR/AR meets the highest standards.