When your hands are sweaty or damp, a silicone phone case feels like a bar of soap. True proof:

- After wearing latex gloves, the chance of a nurse’s mobile phone slipping is 3 times higher

- Rainy days can lead to a decrease of more than 40%

- Factory oil will make the cases permanently slippery

Good news: top phone case manufacturers like YG have integrated grip into the chassis from the very beginning.

4 Simple Ways Manufacturers Make Cases Grippy

Table of Contents

ToggleWe stop slippage with smart design:

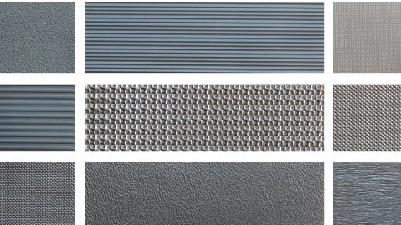

1. Skin-gripping textures (tiny laser-cut patterns)

Working principle: When silicone comes into contact with the skin, the micro-texture acts like a “miniature hook”, embedding into the skin’s concave areas, increasing the contact area and reducing the risk of slipping off.

This not only enhances the stability of the grip but also disperses the pressure points to prevent discomfort.

Skin-gripping textures

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

2. Special Grip Powders Mixed into Silicone

Working principle: Nano-sized particles are added to the silica gel matrix to form a network structure, which absorbs and disperses external impact forces (such as vibration or shock), thereby enhancing the damping (shock absorption) performance of the material from the inside.

This reduces the sliding tendency of silicone while maintaining the material’s lightweight properties.

Nano-additives-fumed silica

3. Surface Adhesion Treatment

Working principle: The surface of silica gel is temporarily treated with plasma (ionized gas) to change its chemical properties and enhance its hydrophilicity or adhesion.

The processing time is only 30 seconds, making the originally hydrophobic silicone more “skin-friendly” or easier to bond with other materials. This is equivalent to laying a foundation for the silicone, providing stronger adhesion for subsequent coatings or contacts.

Supplementary: This technology is environmentally friendly and highly efficient. Compared with chemical treatment, it leaves no residue and conforms to the trend of green manufacturing.

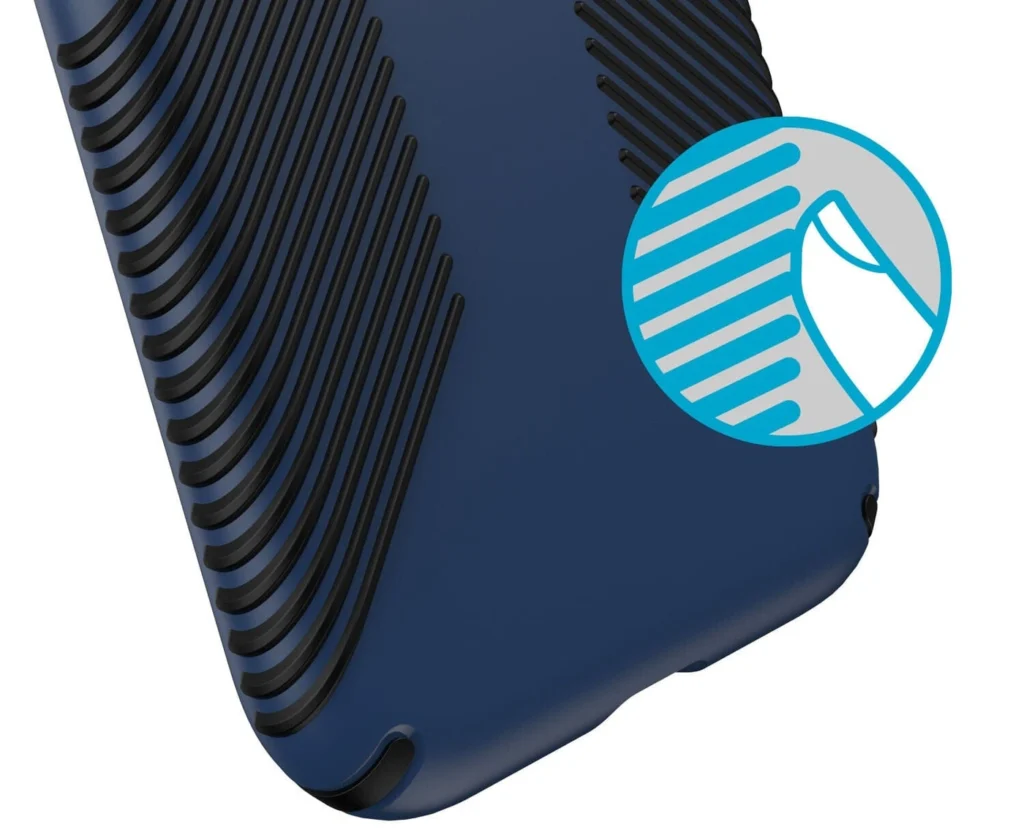

4. A Thumb-friendly Curve that Suits Your Hand

Working principle: By optimizing the shape of the silicone through physical structure design, it conforms to the movement mechanism of the human hand or specific parts, reducing operational fatigue.

Thumb-friendly curves

How to Make An Anti-slip Silicone Mobile Phone Case

① Mix the Material Formula of The Handle

We blend food-safe silicone with gripper enhancers, much like adding sugar shavings to ice cream, to make your phone case anti-slip from the material. Notes:

- Too few supporters = the case will soon slip

- Too much = The box becomes hard

② Mold Making

Choose from a variety of textures (shark skin, hexagonal, etc.), or we can customize the texture structureyou need according to your requirements:

- Laser cutting molds produce precise protrusions(0.05mm depth accuracy)

- Rapid prototyping—Change the design quickly within 12 hours if necessary

Pro tip: Bad patterns can crack – we have fixed over 200 designs

Mobile phone case mold

③ Injection Molding & Curing

Liquid silicone is injected into a precision mold engraved with anti-slip textures through a high-pressure injection molding machine (50-150 MPa), and the texture details are fully filled at a high temperature of 120-180℃.

Subsequently, the same mold is heated to 160-200℃ in a high-temperature vulcanizing machine, triggering a platinum catalyst to initiate a cross-linking reaction (30-120 seconds), converting the liquid silicone rubber into an elastic solid, permanently locking the anti-slip structure and endowing it with a high coefficient of friction (μ=0.8-1.2).

- Standard curing → texture degrades in 30 days

- YG’s method → <8% friction loss after 2,000 abrasion tests

phone case injection molding

④ Surface Treatment

Choose eco-friendly options:

- Plasma coating (best for medical cases)

Over-ionized gases (such as argon and oxygen) form nanoscale coatings on the surface of silica gel, enhancing surface adhesion.

The entire process is free of chemical solvents and conforms to the environmentally friendly characteristics of liquid silicone rubber (LSR), making it suitable for your high-end phone case accessories

- Non-toxic matte spray (cost-efficient for e-commerce)

Based on the optimization of pad printing/screen printing processes and the application of water-based matte resin spraying,

the phone case you receive has a fine frosted texture, meeting the daily anti-slip requirements and adapting to the demand for quick delivery. Its cost is approximately 40% lower than that of plasma coating

Find Your Anti-slip Phone Case Solution

| Type | Best For | Grip Level | YG’s Special Sauce |

|---|---|---|---|

| Everyday Hero | Online stores | ★★★☆☆ | 200+ texture options |

| Adventure Pro | Hiking brands | ★★★★☆ | Sweat-draining grooves |

| Life-Saver | Hospitals/factories | ★★★★★ | Germ-fighting armor |

Easily Pass Global Compliance (YG Guarantee)

Using our pre-tested solution can avoid a fine of 50,000 US dollars:

- Eu REACH: Additives do not contain phthalates

- California Proposition 65: BPA-free certification

Test the Anti-slip Quality Like a Professional

Before mass production, please conduct the following verifications:

- Tilt test: The mobile phone must not slide below 35°

- Olive oil swab: Simulate sweaty palms

Why do brands like to collaborate with YG

Core differentiators:

- The defect rate is 30% lower than the industry average

- By adopting MUD technology, the time to market for products has been shortened by 40%

- One-stop compliance: REACH/FDA/ISO pre-certification

Get Your Perfect Grip Case (Free Start Kit)

❶ Grab our Anti-Slip Cheat Sheet

❷ Email us within 72 hours to indicate

Stop slippage now →

.webp)