This project involved the development of a flagship protective case for a leading European mobile accessories brand. The objective was to create a product that offers “native tactile feedback” and “long-lasting clarity.” YG provided a comprehensive ODM solution, from mold development to precision injection molding, specifically addressing the common industry challenges of material aging and insufficient impact resistance.

About the Project

Table of Contents

ToggleThe project was led by a European brand committed to minimalist design. Their target audience demands “visual purity” and “physical durability,” requiring a solution that showcases the device’s original logo and color while remaining resistant to yellowing and fingerprints over long-term use.

From an engineering perspective, the product utilizes a PC+TPU hybrid structure. The underlying technical logic involves using the high rigidity and dimensional stability of Polycarbonate (PC) for the backplate to prevent structural deformation. Simultaneously, the frame integrates high-damping Elastic TPU. This setup utilizes the flexible molecular chains of TPU to achieve viscoelastic dissipation of impact energy during a drop, providing redundant protection for sensitive electronic components.

To enhance the biomechanical feedback of the grip, we implemented micro-textured molding on the frame. These textures are machined directly via precision EDM (Electrical Discharge Machining), increasing the coefficient of friction in both dry and humid conditions while providing a refined, textile-like tactile experience.

| Category | Details |

| Industry | Consumer Electronics / Premium Mobile Accessories |

| Product | Frosted Translucent Precision Protective Case |

| Services Provided | ODM/OEM Manufacturing, Rapid Prototyping, Custom Tooling Development |

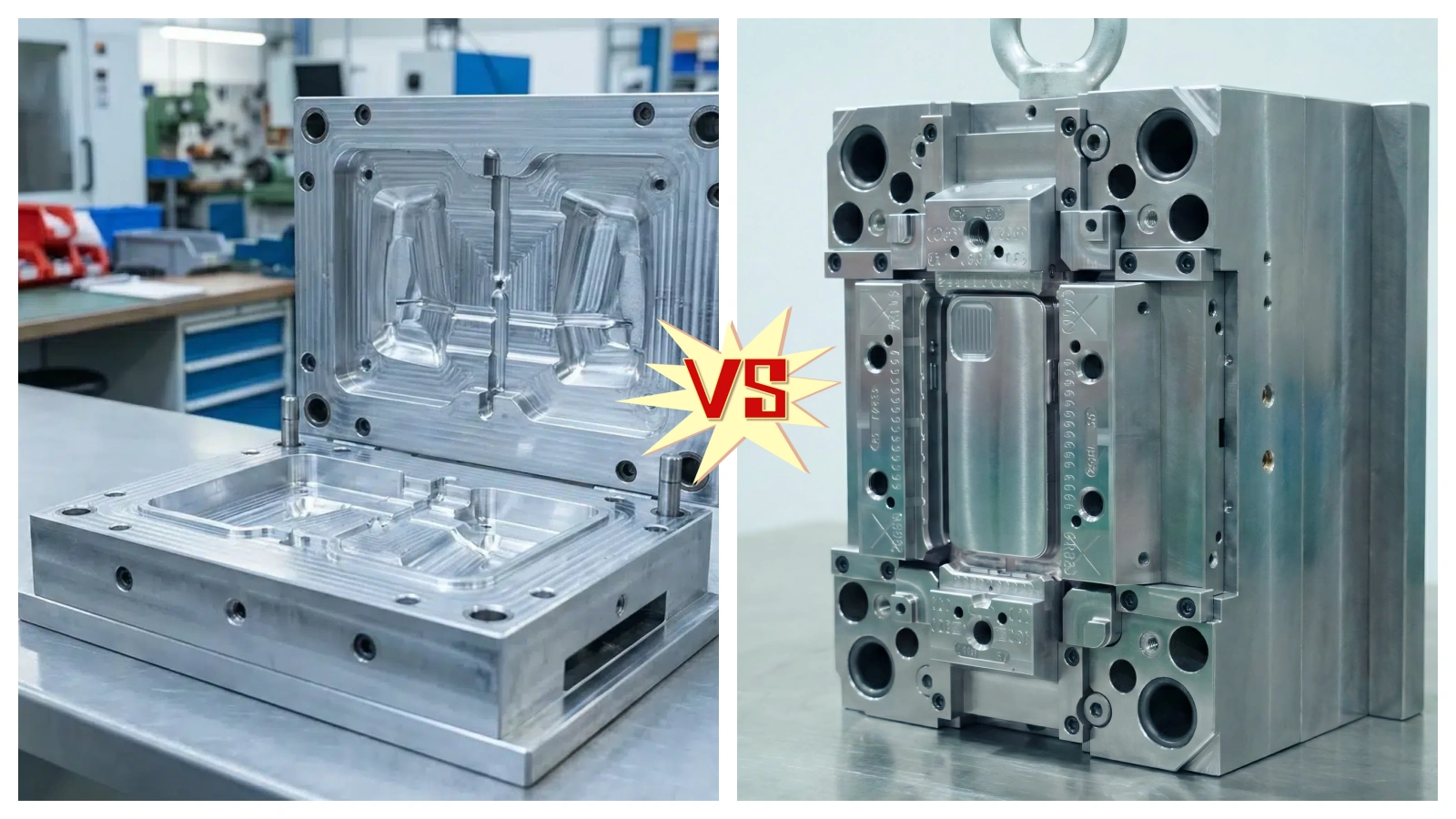

| Technology | High-Precision Multi-material Injection (Overmolding), CNC Tooling |

| Materials | UV-Resistant Polycarbonate (PC), High-Elasticity Thermoplastic Polyurethane (TPU) |

| Surface Treatments | Nano-grade “Baby-Skin” Frosted Coating, Textured Grip, Anti-Yellowing UV Treatment |

The Challenges

Prior to partnering with YG, the brand faced a significant disconnect between product quality and user expectations. A lack of deep understanding of multi-material injection processes in their previous supply chain led to several technical failures:

Material Instability & Photo-oxidation: The previous single-material TPU cases suffered from severe photo-oxidation yellowing within weeks of UV exposure, damaging the brand’s premium image and leading to high return rates on platforms like Amazon.

Physical Protection Constraints: As smartphone camera modules became more prominent, existing molds lacked the necessary raised bezel protection. The client required a precision solution offering a 2.5mm camera lift without compromising the minimalist profile.

Surface Contamination: Conventional glossy cases easily attracted sebum and fingerprints. This made the products look unhygienic and cheap shortly after use, undermining the brand’s mid-to-high-end market positioning.

Grip Failure: Overly smooth surfaces resulted in poor ergonomics, leading to accidental drops and screen damage in outdoor scenarios.

The Solution

YG’s engineering team performed a comprehensive DFM (Design for Manufacturability) assessment, identifying unique requirements for material bonding and surface performance.

Hybrid Injection & Molecular Bonding: To eliminate yellowing, we utilized high-transparency, UV-resistant PC for the backplate, bonded with a flexible TPU frame. Through overmolding technology, the two materials achieve molecular-level bonding under high temperature and pressure.

Nano-scale Frosted Finish: We applied a “Baby-Skin” tactile coating. The process involves precision chemical etching on the mold surface to create micron-level textures. This achieves a sophisticated translucent aesthetic through light diffusion while significantly reducing the effective contact area for sebum, ensuring superior anti-fingerprint performance.

Functional Engineering: * 2.5mm raised camera bezels and 0.8mm raised screen bezels were implemented to ensure “suspended protection” for hardware.

1:1 Precision Fit ensured all ports were perfectly aligned, providing tactile, “clicky” button feedback.

The Results

The collaboration enabled the brand to successfully launch a precision case that excelled in both lab tests and real-world market conditions.

Market Reception: Average product ratings on major e-commerce platforms rose from 3.5 to 4.7 stars.

Reduced After-sales Costs: The precision-engineered bezels led to a 65% reduction in return rates related to accidental screen or camera damage.

Efficient Turnaround: Leveraging YG’s Rapid Tooling technology, the transition from DFM assessment to the first delivery of ISO 2768M-standard units took only 21 days.

“YG’s DFM assessments and prompt modification suggestions allowed us to advance our project much faster than anticipated. They were the only supplier capable of solving the dual challenges of non-yellowing materials and precision protection at a reasonable cost.” —— Supply Chain Director of the Partner Brand

Looking Ahead

Following the success of the frosted translucent series, the brand is expanding its partnership with YG:

Next-Gen Development: Engineering a second-generation hybrid case with integrated MagSafe functionality.

Material Innovation: Exploring bio-based plastics to meet the growing demand for sustainable products in the Western market.

Scalability: Expanding this precision injection process to protective gear for tablets and other portable electronics.

.webp)