Finding a reliable custom Phone Case Manufacturer remains the most daunting hurdle for accessory brands today. In 2026’s hyper-competitive market, a single batch of low-quality cases or a missed production deadline can instantly evaporate your marketing budget and ruin customer trust. You aren’t just looking for a supplier; you’re looking for a foundation.

This guide provides a strategic blueprint to vet manufacturers, ensuring your brand leads the market with cutting-edge materials and a rock-solid supply chain.

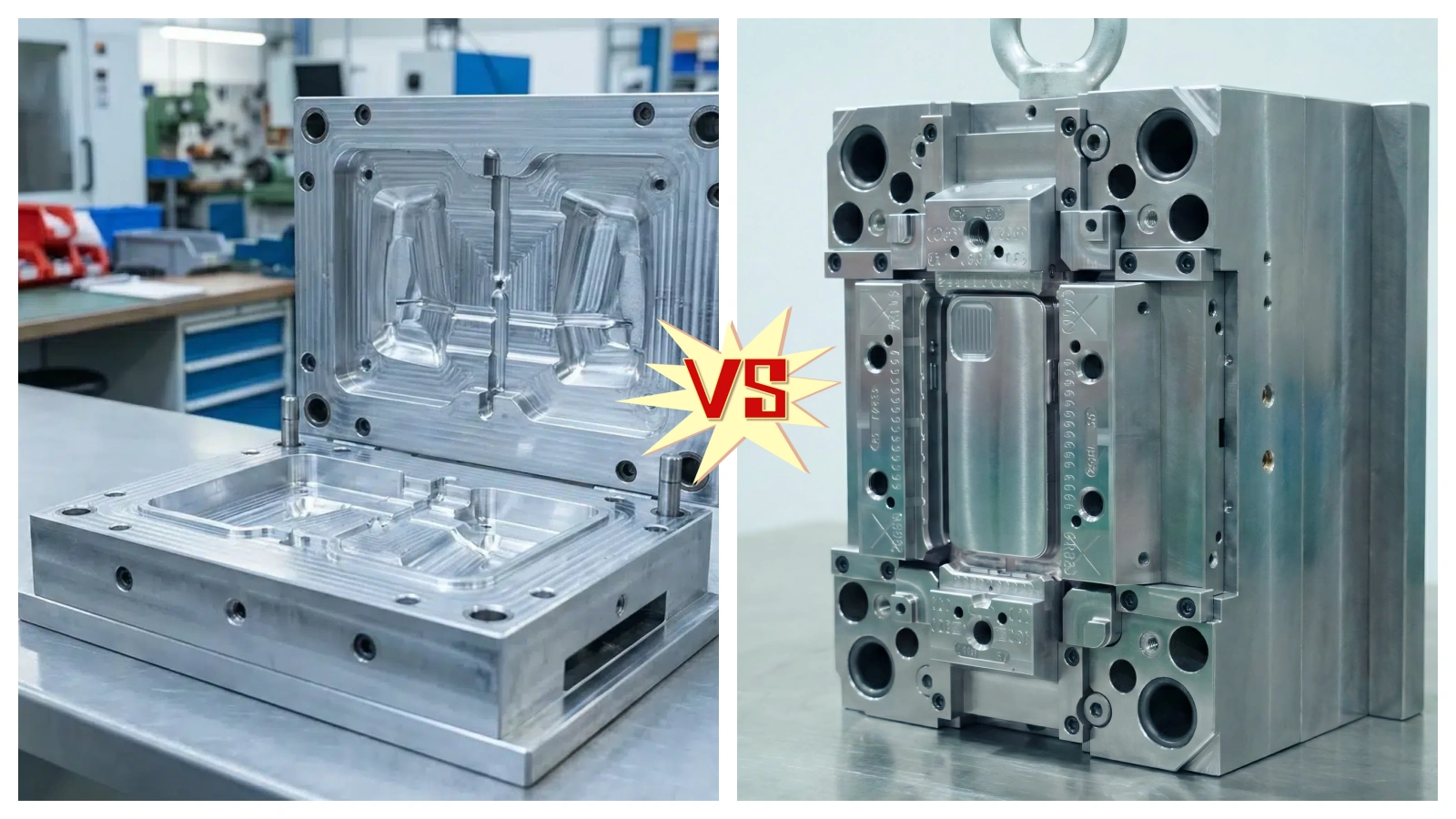

1. Defining Your Needs: OEM vs. ODM Manufacturing Models

Table of Contents

ToggleIn the 2026 mobile accessory market, choosing the wrong production model is a costly mistake. Before scouting a manufacturer, you must determine which OEM/ODM capabilities align with your business goals.

OEM (Original Equipment Manufacturer): Your design, their hands. Best for established brands with in-house design teams seeking 100% product exclusivity.

ODM (Original Design Manufacturer): Their design, your brand. Best for startups looking to launch quickly using existing “public” molds.

OEM vs. ODM: A Strategic Comparison

| Feature | OEM Model | ODM Model |

| Design Ownership | You (The Brand) | The Manufacturer |

| Tooling Costs | High (Custom molds) | Low (Existing molds) |

| Time-to-Market | Slower (R&D required) | Rapid (Turnkey) |

| Differentiation | Maximum | Moderate |

Audit the manufacturer’s patent portfolio. A truly capable ODM partner should have a library of their own innovations, not just copies of existing trends.

Manufacturing Processes of 2026

The Supremacy of IMD/IML Printing Technology

If your manufacturer is still suggesting simple UV printing or silk-screening for premium cases, they are living in 2018. In 2026, IMD (In-Mold Decoration) and IML (In-Mold Labeling) are the industry standards for high-end brands.

How it works: The design is printed on a film, which is then placed inside the injection mold. The plastic resin is injected behind it, effectively “sandwiching” the design between the outer protective layer and the case body.

Why it matters:

Zero Wear: The image is protected by a layer of PET or PC. It cannot be scratched off.

3D Effects: IMD allows for holographic, metallic, and deep-texture effects that flat printing cannot achieve.

Chemical Resistance: It survives daily contact with hand sanitizers and skin oils—a major cause of UV print failure.

Material Science: Beyond Basic TPU

In 2026, “TPU” is too generic. Professional custom Phone Case Manufacturers now utilize multi-material injection (Two-Shot molding or overmolding).

TPU + PC Hybrid: A soft TPU bumper for shock absorption fused with a hard PC back for clarity and structural integrity.

Liquid Silicone (LSR): Offers a “baby-skin” feel and is naturally antimicrobial.

TPE (Thermoplastic Elastomer): Used in the inner ribs of high-impact cases to create air pockets that act as crumple zones.

Scale Equals Quality

A common friction point for new brands is the 1,000-unit Minimum Order Quantity (MOQ). However, understanding the physics of manufacturing reveals why this is a quality safeguard.

Machine Calibration and Scrap Rates

Injection molding machines are industrial giants. Calibrating a machine for a specific mold and material takes 2 to 4 hours. During this “purge” period, the first 50–100 units are often discarded due to color inconsistencies or air bubbles.

The Math of Quality: If a factory accepts an order for 50 units, they cannot afford the calibration time. They will “eye-ball” the settings, leading to high defect rates.

1,000 Units as the Baseline: This volume allows the machine to reach a “thermal steady state,” ensuring that unit #200 and unit #1,000 are identical in molecular density and color accuracy.

Professional Prototyping & Sampling

When you commit to a 1,000-unit run, the Prototyping & Sampling process becomes a rigorous engineering phase.

Stage 1: The CNC Sample. A case machined from a solid block to test fitment.

Stage 2: The Color Match Sample. Using Pantone-accurate pigments.

Stage 3: The Pilot Run. A small batch from the actual production mold.

Never accept a digital mockup as final approval. In 2026, the “tactile” feel—the clickiness of the buttons—is what determines a 5-star Amazon review.

Sustainability: The 2026 “Green” Mandate

The era of “Greenwashing” is over. Regulatory bodies in the EU and US now require verified “Product Passports.” Your custom Phone Case Manufacturer must provide documented proof of sustainability.

Categories of Eco-Friendly Phone Cases

PCR (Post-Consumer Recycled) Plastics: Cases made from recycled water bottles or ocean-bound plastic.

Bio-Polymer Blends: Materials like wheat straw or bamboo fiber mixed with PLA. Note: These must be tested for durability, as some “eco” cases become brittle after 6 months.

Circular Economy Programs: Top-tier manufacturers now offer “Take-Back” programs where they regrind old cases into new raw materials.

Regulatory Compliance Checklist

RoHS & REACH: Essential for the European market.

GRS (Global Recycled Standard): Proof that your “recycled” case actually contains recycled content.

BPA-Free: A health-conscious requirement that is now a standard consumer expectation.

Business Security: Protecting Your Intellectual Property (IP)

Design theft remains the “hidden tax” of the manufacturing industry. Protecting your designs requires a multi-layered legal and operational strategy.

The NNN Agreement vs. The Standard NDA

In international manufacturing, a Western NDA is often unenforceable. You need an NNN Agreement:

Non-Use: They cannot use your design to sell their own products.

Non-Disclosure: They cannot show your design at trade shows or to other clients.

Non-Circumvention: They cannot contact your distributors to sell them your design directly.

Operational Security

Segmented Files: Send the front-frame CAD file to one engineer and the back-plate CAD to another.

On-Site Audits: In 2026, you can hire “Digital Auditors” who use body-cams to perform unannounced factory floor checks to ensure your exclusive molds aren’t being used for “midnight runs.”

Financial Decisions: Beyond the “Per-Unit Cost”

The lowest quote is rarely the most profitable. Focus on the Total Cost of Ownership (TCO).

Landed Cost Formula:

(Unit Price + Shipping + Tariffs + QC) / Total Sellable Units.The Defect Factor: A 5% defect rate on a “cheap” order is more expensive than a 0% defect rate on a premium order.

Negotiation Tip: Ask for “Tooling Amortization”—spreading the mold cost over your first 5,000 units to preserve your initial cash flow.

FAQ

Q1: How can I tell if a supplier is a real factory or a middleman?

A1: Real manufacturers focus on 1–3 specific materials. Request a live walkthrough of the production line via video call. Verify their ISO 9001 certificate against their business license.

Q2: How do manufacturers handle unreleased models?

A2: Elite partners use leaked CAD data to create “pre-molds” 3 months before launch. Final precision adjustments are made within 48 hours of the official phone release.

Q3: How do I ensure my clear cases won’t turn yellow?

A3: Request premium resins like Bayer (Germany). Always ask for a 96-hour UV accelerated aging test report during the prototyping phase to ensure a Level 4.5 anti-yellowing rating.

Q4: What are the expected production lead times in 2026?

A4: Prototyping takes 5–7 days, while mass production for 1,000+ units takes 10–15 days. Always factor in a 7-day buffer for international DDP shipping.

Conclusion

Choosing a custom Phone Case Manufacturer in 2026 is no longer a transaction; it is a long-term alliance. The brands that win are those that understand the technical nuances of Prototyping & Sampling, respect the quality-logic behind a 1,000-unit MOQ, and prioritize IP protection.

The mobile accessory market is unforgiving to those who cut corners. But for those who invest in quality, sustainability, and innovative manufacturing processes, the rewards are immense. Your brand is only as strong as your supply chain. Choose wisely.