Injection mold manufacturing is the foundation of modern precision production, providing support for key industries such as automobiles, medical care, electronics, home appliances, and semiconductors. Its role in ensuring product quality, production efficiency, and design flexibility makes it an indispensable element for enterprises in global market competition.

In recent years, Chinese injection mold manufacturers have gained widespread recognition due to their advanced technical expertise, rigorous quality control systems, and adherence to global compliance standards.

This blog highlights 10 leading Chinese injection mold manufacturers, aiming to help global customers identify their ideal partners. Whether you need precision injection molds, large automotive molds, or professional medical-grade solutions, the following information will guide your decision-making process.

Why Choose Chinese Injection Mold Manufacturers

Table of Contents

ToggleChinese injection mold manufacturers stand out in the global market with unique competitive advantages, meeting the diverse needs of international clients.

- Master advanced technologies such as 5-axis machining, multi-shot molding, and MuCell foaming, delivering molds with tolerances as tight as ±0.003mm.

- Hold international certifications including ISO 9001, IATF 16949, and ISO 13485, complying with global quality and environmental standards.

- Boast large-scale manufacturing bases and automated production lines, supporting both small-batch customization and mass production.

- Provide integrated solutions from product design, mold development, prototyping, to mass production and after-sales support.

- Establish overseas branches, offices, and logistics partnerships, ensuring efficient cross-border communication and delivery.

Top 10 Chinese Injection Mold Manufacturers

The selection of these 10 leading injection mold manufacturing companies is based on a rigorous assessment of the core capabilities that are most important for global cooperation. We analyzed key factors, including technical expertise, international compliance qualifications, industry experience, global service coverage, and production scalability.

Let’s discuss them in detail

1. YG Tech

| Company Name | Founded | Location | Specialties | Certifications |

| YG Tech | 1996 | Humen Town, Dongguan City, Guangdong Province, China | Two-shot injection molding, overmolding, plastic injection mold making, liquid silicone rubber products, one-stop solutions | SO 13485 / ISO 9001 ISO 14001 / Reach / RoHS / GRS 4.0 |

YG‘s business scope covers the consumer electronics, smart devices, AR/VR, and daily necessities industries, focusing on high-precision mold customization and integrated manufacturing solutions. It specializes in two-injection molding, overmolding, and liquid silicone rubber molding – these technologies are suitable for complex product designs that require multi-material integration or ultra-high precision.

Its core service advantage lies in the all-round support throughout the entire life cycle: from industrial design and mold development to mass production, packaging, and third-party logistics.

With precise control at the 0.01-millimeter level and strict quality inspection during the entire mold processing and production, YG ensures consistent mold performance and product reliability. It serves global customers, emphasizing flexibility. It can not only meet the demands of small-batch customized projects but also carry out large-scale mass production, while maintaining a competitive delivery cycle and transparent pricing approach.

2. Shenzhen Changhong Technology

| Company Name | Founded | Location | Specialties | Certifications |

| Shenzhen Changhong Technology | 1997 | Pingshan, Shenzhen, China | High-precision injection molding, precision mold manufacturing, medical consumables molds, semiconductor consumables molds, OA equipment molds | ISO 9001, IATF 16949, ISO 13485, ISO 14001, FDA |

As a national high-tech enterprise, its business scope covers medical consumables, intelligent manufacturing and semiconductor consumables. The company operates a 4,000-square-meter 100K-level clean room for the production of medical molds, equipped with 70 CNC processing and measuring devices, as well as over 180 precision forming machines.

The company’s annual production capacity reaches 500 sets of molds and 6,000 tons of plastic components, and it also has an assembly capacity of 10 million sets.

It holds over 30 design and innovation patents and collaborates with Dinglong Holding Group to produce semiconductor-related components.

3. Dongguan Chitwing Technology

| Company Name | Founded | Location | Specialties | Certifications |

| Dongguan Chitwing Technology | 2007 | Chang’an Town, Dongguan City, Guangdong Province, China | Precision mold design and manufacturing, plastic/metal precision structural parts, stamping molds, CNC machining, surface treatment | ISO 9001, ISO 14001, ISO 13485, ISO 27001, ISO 45001 |

Chitwing serves the 3C electronic devices, smart wearable devices, automotive and medical industries, specializing in providing precision tools for smartphone structural components, wearable device casings, automotive lightweight parts and medical device casings.

It holds 152 domestic patents (including 53 invention patents) in core technologies such as alloy mold injection molding and IP68 waterproof mold design. Its global network includes branches in South Korea and Vietnam as well as an office in the United States, enabling localized communication and rapid response. With an annual production capacity of 2,000 sets of precision molds and 130 million structural components, it strikes a balance between small-batch customization and large-scale production efficiency.

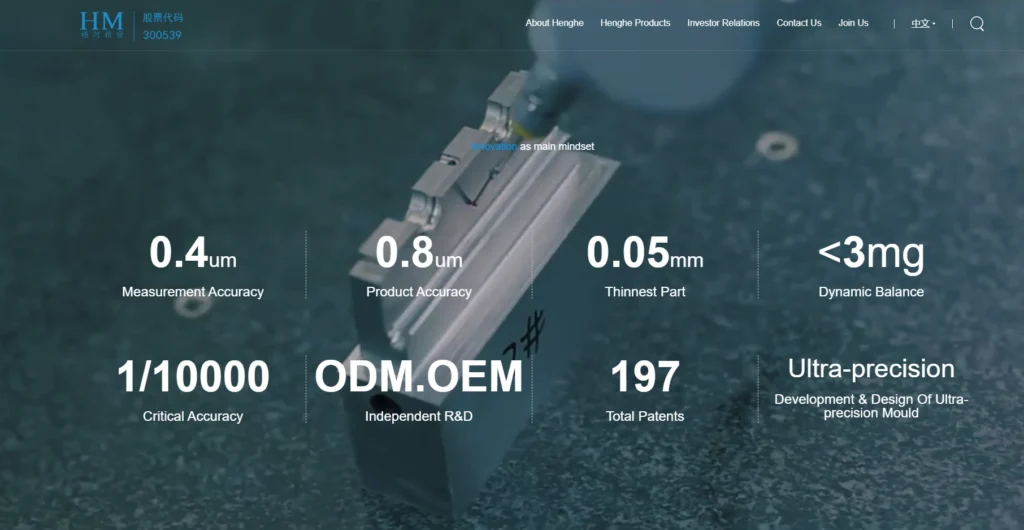

4. Ningbo Henghe mould

| Company Name | Founded | Location | Specialties | Certifications |

Ningbo Henghe mould | 1992 | Cixi City, Ningbo, Zhejiang Province, China | Precision injection molds, product design, molding production, assembly, automotive parts molds, medical device molds, home appliance molds | ISO 9001, REACH |

Henghe’s business scope covers industries such as household appliances, automobiles, medical care and sanitary ware, and it produces molds for smart toilet components, automotive interior parts, medical protective equipment and kitchenware shells.

The company offers one-stop services from product design to final assembly and has established long-term cooperative relationships with global brands such as Panasonic, Dyson and SAIC Motor. Its advanced quality control system and REACH compliance system ensure that the molds meet European environmental and safety standards. The company’s multi-regional subsidiaries enable it to flexibly allocate production resources and shorten delivery times to global customers.

5. Kaihua Mould

| Company Name | Founded | Location | Specialties | Certifications |

| Kaihua Mould | 2000 | Huangyan District & Sanmen County, Taizhou, Zhejiang Province, China | Large precision automotive lightweight molds, plastic injection molds, custom mold solutions, MuCell foaming technology | ISO 9001, ISO 1400, ISO 1800 |

Kaihua focuses on the automotive and heavy industry sectors, specializing in manufacturing large and precise molds for automotive door panels, bumpers, center consoles, and lightweight structural components.

As a “China Key Export Mold Enterprise”, it has set up offices in Brazil and Spain to serve global automotive customers. The company is equipped with a 3300T high-speed injection molding machine and an intelligent production line. It excels in the manufacturing of large molds and has strict dimensional control capabilities. Its experience in participating in national industrial projects highlights its technological leading position in the field of automotive lightweight mold innovation.

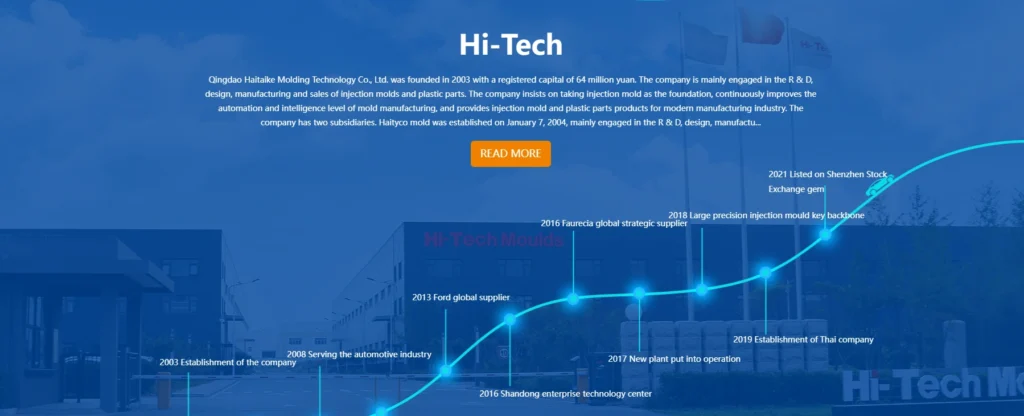

6. Qingdao Hitech Moulds

| Company Name | Founded | Location | Specialties | Certifications |

| Qingdao Hitech Moulds | 2003 | Qingdao, Shandong Province, China | Automotive injection molds, plastic parts, mold design and manufacturing, project management services | IATF 16949, ISO 9001, RoHS |

Hitech mainly serves the automotive industry, providing injection molds and plastic components, covering automotive interiors, exteriors and functional parts, as well as molds for battery casings of new energy vehicles (NEVs).

It has a technology center staffed with over 100 engineers, providing flow analysis and product manufacturability optimization services. Support MuCell foaming, gas-assisted injection molding, and two-color molding. Its IATF 16949 certification and solid cooperative relationships with global automakers ensure compliance with the quality standards of the automotive industry. Meanwhile, the automated production lines enhance efficiency and consistency.

7. Silver Basis

| Company Name | Founded | Location | Specialties | Certifications |

| Silver Basis | 1993 | Bao’an District, Shenzhen, Guangdong Province, China | Large precision molds, automotive molds and parts, 3C product structural parts, hot runner control systems, industrial design | ISO 9001, IATF 16949, ISO 14001, UL |

Silver Basis serves the automotive, 3C electronics and industrial equipment industries, specializing in providing large precision molds for automotive chassis components, 3C product structural components and custom hot runner systems.

The company has 7 manufacturing bases in China and service outlets in 18 countries, thus enabling localized delivery on a global scale.

With over 200 patents and more than 270 senior engineers, we provide high-quality mold products for global 3C giants and automotive original equipment manufacturers.

80% of its products are exported to Europe, the United States, and Japan. With its rich experience in manufacturing management, it has achieved smooth cross-border cooperation.

8. TK Group

| Company Name | Founded | Location | Specialties | Certifications |

| TK Group | 1983 | Guangming District, Shenzhen, China | Injection molds, injection molding components, surface treatment, one-stop plastic solutions, medical product molds, automotive molds | ISO 9001, ISO 14001, ISO 45001, ISO13485, IATF16949 |

TK Group’s business scope covers the smart device, medical, automotive, and household appliance industries, providing molds for smartphone casings, medical devices, automotive interior parts, and household appliance components.

TK offers a one-stop solution ranging from mold development to surface treatment and assembly, with 4 production bases covering a total area of approximately 180,000 square meters.

The company has established cooperative relationships with international brands such as Nintendo, ABB, and Mindray Medical, and adheres to ROHS and REACH standards to expand global market access channels. A newly-built large-scale production base in Shenzhen will further enhance its capacity to handle large orders.

9. Voke

| Company Name | Founded | Location | Specialties | Certifications |

| Voke | 2005 | Xiamen, Fujian Province, China | Precision injection molds, plastic products, mold integration solutions, automotive molds, medical molds, electronic product molds | ISCC, ISO 9001, ISO 13485, ISO/TS 16949, ISO 14001 |

Voke serves the automotive, medical, electronic, and industrial supplies industries, specializing in the production of precision molds for medical catheters, automotive sensors, electronic connectors, and industrial components.

It is recognized as a “National Intelligent Manufacturing Demonstration Factory”, has 7 global production subsidiaries, and participates in the formulation of national standards.

Its comprehensive industrial chain has reduced costs and improved efficiency, while the ISO 13485 certification ensures the compliance of medical molds. It provides customized solutions for Fortune 500 companies and has expertise in multi-material and micro-precision mold technology.

10. Hisense Mould

| Company Name | Founded | Location | Specialties | Certifications |

| Hisense Mould | 1996 | Qingdao, Shandong Province, China | Large injection molds, stamping molds, automotive molds, home appliance molds, structural optimization | ISO 9001, ISO14001, ISO45001 |

Hisense Mould belongs to hisense group and serves the automotive and home appliance industries. It produces large injection molds for manufacturing automotive bumpers, door panels and home appliance shells, as well as stamping molds for manufacturing structural components.

It supplies to global automakers such as General Motors, Mercedes-Benz, BMW and Volkswagen, and has a team of more than 10 structural design engineers specializing in mold flow and mechanical analysis. Its annual production capacity of over 1,500 large and medium-sized injection molds ensures scalability under high-volume orders, while the IATF 16949 certification guarantees compliance with automotive quality standards.

Key Factors in Choosing Chinese Injection Mold Manufacturers

When choosing a Chinese mold manufacturing partner, global customers should give priority to the following key factors to ensure a successful cooperation.

- Evaluate the professional level in industry-specific mold technology, precise control, and innovation capabilities (such as patent holding).

- Verify international certifications (such as ISO9001, IATF16949, IS013485, etc.) and compliance with regional quality and environmental standards.

- Evaluate the manufacturing scale, equipment level, and delivery capacity to meet current and future production demands.

- Confirm the global service coverage, overseas branches/offices, and multilingual communication support.

- Check the cooperation records with international clients and relevant industry cases to ensure familiarity with the industry.

- Inquire about the mold warranty policy, maintenance services, and the responsiveness of technical support.

Practical Tips for Cooperating with Chinese Injection Mold Manufacturers

To maximize the effectiveness of cooperation with Chinese mold manufacturers, please consider the following practical suggestions.

- Provide detailed product drawings, material specifications, and quality standards to align with the expectations of both parties.

- Regular technical discussions are held to address mold design, process optimization, and potential issues.

- Thoroughly inspect and test the samples before mass production to ensure they meet the requirements.

- Establish fixed communication channels and response mechanisms to achieve efficient information exchange.

- Collaborate to handle logistics and customs clearance arrangements to ensure the timely delivery of molds and products.

FAQ

1. What is the typical lead time for mold production from these manufacturers?

2. Do these manufacturers accept custom mold development?

3. What industries do these mold manufacturers mainly serve?

4. How do these manufacturers ensure mold quality and precision?

5. Do they provide after-sales support for overseas clients?

Conclusion

The top 10 injection mold manufacturers in China introduced in this blog post possess strong technical capabilities, comprehensive global compliance, and rich international cooperation experience. From precision injection molds to large automotive molds, from medical-grade molds to electronic product molds, these manufacturers can meet the diverse market demands.

By choosing appropriate partners based on factors such as technical expertise, industry experience, and global service capabilities, global enterprises can leverage China’s advantages in mold manufacturing to enhance product quality, reduce costs, and gain a competitive edge in the international market.

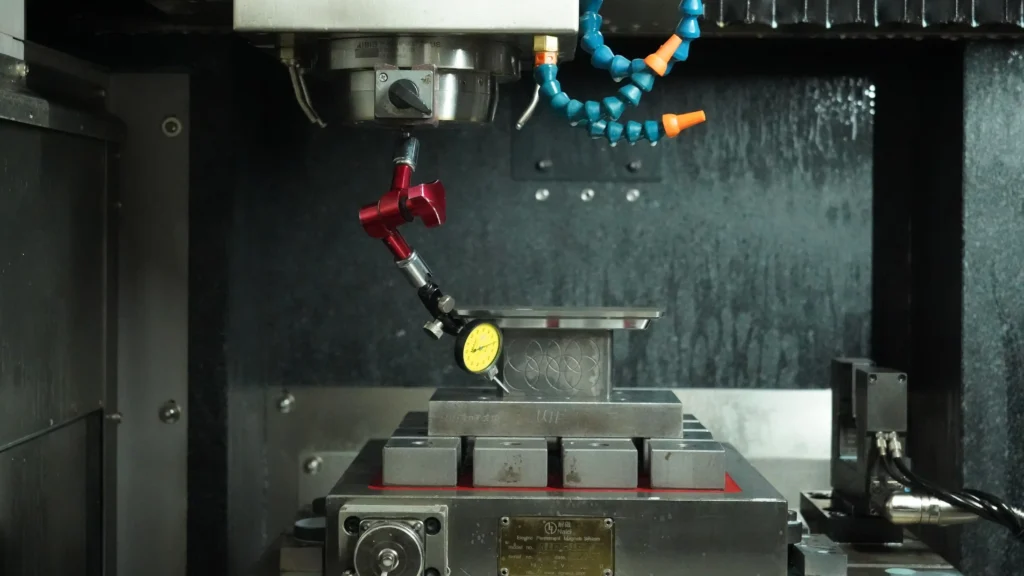

You can choose YG Tech to provide you with custom plastic molds and injection molding services. We offer tailor-made solutions to meet your specific needs. We use the most advanced five-axis CNC, EDM, and wire cutting equipment for injection mold manufacturing, and employ advanced injection molding equipment to produce plastic products for you.