Choosing the right prototype material can make your phone case development process. Wrong choices can lead to iteration delays, cost waste, and the prototype not matching the vision of the final product.

As an experienced phone case manufacturer, YG has made meticulous material selections in thousands of projects. This guide breaks down everything you need to know to make an informed choice regarding features, costs, and speed.

The Importance of Choosing Prototype Materials

Table of Contents

ToggleYour prototype is not merely a sample – it is a test of the feasibility, manufacturability, and user appeal of your design. The material you choose directly affects how it imitates the final product.

Improperly selected materials may look good, but the functional test fails, or within the budget, the release is delayed due to processing issues. For you, the goal is that the materials align with the unique requirements of your project.

Whether you are verifying a new shockproof design or enhancing the clarity of a transparent casing, the right material can transform your digital concept into a usable and reliable prototype.

6 Considerations When Choosing Prototype

Materials

1. Material Performance Alignment

The success of your prototype depends on the degree to which the material properties match the core functions of the product. If you are building a heavy-duty casing, you should give priority to impact resistance and durability.

For a thin, light and transparent model, emphasis should be placed on lightweight, optical clarity, and scratch resistance. Don’t overlook environmental factors – phone cases for outdoor use need to be made of waterproof materials.

Match mechanical properties (strength, flexibility) and physical characteristics (heat resistance, chemical stability) according to your usage scenarios to avoid expensive rework.

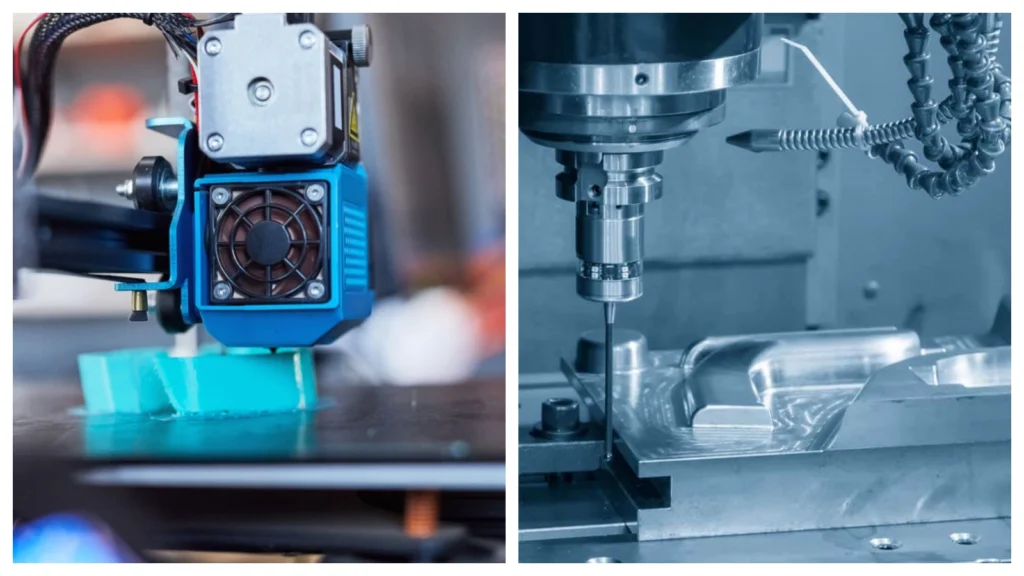

2. Process Compatibility

Not all materials are suitable for every rapid prototyping method. FDM3D printing is suitable for ABS or PLA, while SLA requires photopolymers to achieve high precision.

Consider the interaction between the material and the process you have chosen – some materials require additional steps (such as supporting structures), which will increase time and cost.

Make sure your materials match the subsequent large-scale production: Prototypes using injection-molded TPU will transition more smoothly to large-scale manufacturing.

3. Cost Control

Budget is of vital importance – material costs far exceed the price per pound. Processing fees, equipment wear and tear, and post-processing costs (for example, making metal prototypes) need to be taken into account.

Cheap materials like PLA can save upfront costs, but they may fail in functional tests, leading to more iterations. The initial cost and long-term efficiency need to be balanced.

For small-batch concept testing, choose economical plastics; Reserve high-quality materials (such as carbon fiber) for the final functional prototype.

4. Precision & Detail Replication

If your design contains complex details – such as fine textures, fine edges, or snap-on closed structures – your materials must accurately replicate these details.

Attention should be paid to the low shrinkage rate and dimensional stability to avoid prototype deformation. Thin-layer 3D printing materials (such as resin) are good at fine details but take longer to print. Don’t sacrifice precision for the sake of speed – imprecise prototypes may mislead your design decisions.

5. Post-Processing Needs

Some materials can be used directly after printing. While others require sanding, painting, or curing. Please consider how much additional work you are willing to invest.

Plastics like ABS usually need to be polished to achieve a smooth surface, while metal prototypes may require anodizing to prevent corrosion.

Post-processing can enhance performance but increase costs – please select materials that match the team’s capabilities and schedule.

6. Support Structures & Stability

Complex designs (for example, hollowed-out patterns, overhanging structures) require support during the printing process – but certain materials can minimize this trouble to the greatest extent. For instance, SLS nylon does not require support.

Consider how difficult it is to easily remove the support without damaging the prototype. Fragile materials like resin may crack if the support is overly pulled.

Give priority to materials that can maintain structural integrity during the printing process to avoid warping or sagging.

Classification of Prototype Materials

1. Plastic Materials (Most Versatile Category)

1.1 Commodity Plastics

ABS (Acrylonitrile butadiene styrene)

ABS is the main force of functional prototypes, which is affordable, strong, and easy to process. It performs well in terms of wear resistance and handling basic impact tests.

Ideal for FDM printing, CNC machining, or injection molding, it is the perfect test chassis structure, buttons, or fasteners.

Note: It has moderate heat resistance (for continuous use up to 70°C) and may require a frosted finish to achieve a smooth surface.

Polylactic acid (PLA)

As a biodegradable and low-cost option, PLA is excellent for early-stage concept prototypes. It features fast printing speed, high precision, and bright colors.

Use it to verify design aesthetics or test basic forms – avoid functional testing as it is fragile and prone to cracking under pressure.

It is both environmentally friendly and cost-effective, making it an ideal choice for brainstorming meetings or client presentations.

PP(polypropylene)

Lightweight and flexible, PP excels in chemical resistance and fatigue resistance, making it highly suitable for waterproof phone cases or thin, flexible designs.

Compatible with injection molding and CNC machining, it is a reliable choice for testing water resistance or flexibility.

Pay attention to the higher shrinkage rate – calibrate your printer or mold to maintain the size.

1.2 Engineering Plastics

PC(Polycarbonate)

PC offers unparalleled impact resistance, optical clarity, and heat resistance (up to 120°C). This is the gold standard for transparent, heavy-duty case prototypes.

For FDM printing, CNC machining, or injection molding – ideal for testing drop resistance or durability of transparent casings.

Upgrade to PCR regenerated PC to achieve sustainability without sacrificing performance (30-50% regenerated components).

Nylon (PA)

The strength, flexibility, and wear resistance of nylon make it an ideal choice for moving parts, such as watch case hinges or adjustable straps.

It works in combination with SLS 3D printing and CNC machining to handle friction and reuse better than most plastics.

Store it in a dry environment – nylon will absorb moisture, which will affect the print quality.

POM(Polyoxymethylene)

POM features rigidity, low friction, and dimensional stability – making it highly suitable for sliding components or precisely fitted housing assemblies.

For prototypes that need to withstand repeated assembly and disassembly, CNC machining or injection molding can be adopted.

Avoid high temperatures during processing – polyoxymethylene will decompose and release harmful fumes.

PEEK(Polyetheretherketone)

PEEK is a high-performance material suitable for extreme environments – it can withstand temperatures up to 260° C and chemical corrosion.

It is very suitable for professional uses (such as medical or outdoor equipment), but it is very expensive.

CNC machining or high-temperature 3D printing is suitable for small-batch, high-value prototypes.

2 Elastomers/Rubber Materials

Silicone

The high elasticity, water resistance, and soft texture of silicone make it highly suitable for use in shock-absorbing layers or fully enclosed soft cases.

It is suitable for injection molding or mold casting and can precisely replicate textures (such as grip patterns).

Note: Dust may be adsorbed after injection molding – it is recommended to consider matte surface treatment or coating to enhance usability.

TPU (Thermoplastic polyurethane)

TPU strikes a balance between flexibility and durability, featuring excellent wear resistance and dyeability. It’s the top choice for hybrid hard-soft cases.

Compatible with FDM/SLS printing, injection molding, and CNC machining, it is suitable for functional testing.

Regenerated TPU can be chosen to reduce the carbon footprint without sacrificing performance.

3. Resin Materials (High-Precision Choice)

Photopolymers (SLA-Specific)

Photopolymers cure under ultraviolet light, providing ultra-high precision (error ≤0.1 mm) and smooth surfaces. It is highly suitable for SLA 3D printing and is an ideal choice for complex designs such as lace patterns or fine detail logos. They are brittle, so they are used for appearance prototypes rather than impact tests. Post-curing can enhance stability.

Elastic Polyurethane (EPU)

EPU imitates the flexibility and tear resistance of rubber, making it highly suitable for soft-case prototypes or shock-absorbing components.

It is suitable for SLA printing, but the printing speed is slower than that of standard resin. It can be used to test the grasping or buffering performance. Compared with the base resin, it is more expensive – it is recommended to reserve it for functional soft-touch components.

Clear Resin (VeroClear)

VeroClear offers transparency and UV resistance close to that of PC, making it highly suitable for high-end transparent housing prototypes.

Compatible with MJF and SLA printing, it can prevent yellowing and maintain clarity for a long time

It is more expensive than standard resin, but it eliminates the need for coating after printing.

4. Metal Materials (High-Strength Needs)

Aluminum

Lightweight and sturdy, aluminium is highly suitable for use in case frames, brackets, or heavy-duty outdoor boxes.

For prototypes that require structural rigidity but have no extra weight, CNC machining or DMLS3D printing can be used.

Anodic oxidation treatment is applied to the surface to prevent corrosion and increase color options.

Stainless steel

The corrosion resistance and hardness of stainless steel make it highly suitable for use in sturdy and durable casings (for example, in military or industrial applications)

It supports DMLS printing and CNC machining, but has higher processing costs and longer delivery cycles.

It is heavier than aluminium – suitable for situations where durability is uncompromising.

Titanium alloy

Titanium alloys have an unparalleled strength-to-weight ratio and excellent resistance to extreme environments.

It is very suitable for high-end custom cases or medical-grade accessories, but the cost is relatively high.

For small-batch prototypes, it is recommended to use DMLS printing or CNC machining – its biocompatibility enhances the multi-functionality of the product.

5. Hybrid/Composite Materials

Carbon fiber composites

Carbon fiber is ultra-light and strong, with a fashionable and high-tech appearance. It is very suitable for high-end slim phone cases.

Compatible with CNC machining and compression molding, it can enhance rigidity without increasing weight.

Note: It is costly and requires special processing – suitable for final prototypes or high-end products.

Glass Fiber-Reinforced Polymers

These materials can enhance the strength and heat resistance of base plastics such as PC or nylon.

They are suitable for injection molding and CNC machining, and are very suitable for cases that require additional durability but do not want to increase the weight of the metal.

Make sure to process correctly to avoid fiber exposure; otherwise, it may damage the surface treatment effect.

Prototyping Material & Rapid Prototyping Process Compatibility Guide

1. 3D printing compatibility

- FDM(Fused Deposition Modeling): Most suitable for ABS, PLA, PC, TPU- applicable to functional prototypes and small-batch production (<50 pieces).

- SLA(Light Curing Molding): Suitable for photopolymers, elastic resins, and transparent resins – highly suitable for high-precision appearance prototypes.

- SLS(Selective Laser Sintering): Suitable for nylon, TPU, and stainless steel powders – complex designs require no support.

- DMLS(Direct Metal Laser Sintering): Suitable for aluminum, titanium alloys, stainless steel – high-strength metal prototypes.

- MJF(Multi-Jet Fusion): Suitable for nylon and transparent resin – balancing precision and speed in medium-batch prototypes (50-500 pieces).

2. Traditional Processing compatibility

- CNC machining: Suitable for metals (aluminum, stainless steel), engineering plastics (PC, POM, PEEK), and composite materials – high precision for functional components! Injection molding: Suitable for ABS, PC, TPU, silicone – ideal for large-scale prototypes (>500 pieces) and mass production alignment.

- Mold casting: Suitable for silicone and resin – ideal for materials and complex textures.

YG’s Prototype Material Selection Guide (By Scenario)

1. By project Phase

- Conceptual design: Choose PLA or base resin – fast, economical, and very suitable for verifying appearance.

- Functional test: Select ABS, PC, or TPU- their mechanical properties match those of mass-produced materials.

- Pre-production: Use the same materials as the final product (e.g., injection-molded TPU, recycled PC)- test manufacturing feasibility.

2. By product function

- Shockproof cases: High-toughness TPU, silicone, or carbon fiber composite material – with priority given to shock absorption.

- Clear cases: PC, transparent resin (VeroClear)- emphasizing clarity and UV resistance.

- Lightweight and portable cases: PP, aluminum, or carbon fiber – balancing weight and structural integrity.

- Extreme usage scenarios (high temperature/corrosion): PEEK, stainless steel, or high-temperature resistant PC- durability is the top priority.

3. By Process & Budget

- Low-cost rapid prototyping: FDM printing +PLA/ABS- suitable for <50 concept samples.

- High-precision appearance: SLA printing + photopolymer/transparent resin – perfect for fine design.

- Medium-batch functional prototypes: Injection molding +PC/TPU- high cost performance for over 500 pieces.

- High-end custom prototype: CNC machining + carbon fiber/titanium alloy – suitable for high-value, small-batch projects.

FAQ

Q: Should I choose plastic or metal for my phone case prototype?

A: Start with your core needs first. Plastics (ABS, PC, PLA) are lighter, cheaper, and more suitable for appearance/light use, while metals (aluminum, stainless steel) are suitable for high strength, durable designs. To achieve a balanced effect, you can try using carbon fiber composite materials.

Q: What is the best material for a functional phone case prototype?

A: It depends on your test requirements: impact resistance (TPU/PC mixture), durability (nylon /ABS), heat resistance (PEEK), or flexibility (silicone /TPU). Match materials with key functional requirements.

Q: Can 3D printing materials be used for large-scale production?

A: Some can (for example, injection molded TPU/PC), but most 3D printing-specific materials (PLA, photopolymers) are too costly for mass production. YG tests material compatibility from prototype to production to ensure consistency.

Q: Are eco-friendly materials less durable than traditional options?

A: Top-grade recycled PC/TPU and bio-based materials meet the same mechanical standards as virgin materials. We offer tensile strength, impact resistance, and durability test reports.

Q: What are the common post-processing steps for prototype materials?

A: Plastic: grinding, painting, welding. Metals: Anodizing, electroplating, and passivation. Resin: Post-curing, polishing. YG suggests choosing the post-treatment process based on the material and design goals.

Conclusion

Your prototype material is far more than just a building material – it is a strategic decision that influences every stage of the phone case development process. By effectively integrating performance, process, cost, and your unique requirements, create a prototype that truly represents the final product.

As a trusted phone cases manufacturer, YG offers a comprehensive range of prototype material options and can provide rapid prototyping services to ensure that your prototypes can smoothly transition to the mass production stage.

Are you ready to start? Contact YG immediately for guidance on your custom prototype material service.