For products made through injection molding, mold investment has a direct impact on production costs and market competitiveness. Suppose you are confused by the fluctuating injection mold quotations or want to avoid overspending.

In that case, this guide will use phone cases as an example to break down the key cost drivers of injection molding tooling, allowing you to make more informed decisions for your business.

Core Factors Affecting Plastic Injection Mold Costs

Table of Contents

Toggle1. Injection Mold Material Selection

Aluminum injection molds: Highly suitable for small-batch production or prototype making. Aluminum cools down faster than steel, thus accelerating the production cycle and making it easier to machine – therefore, the upfront cost of these molds is significantly lower.

However, the drawback is that its service life is relatively short and its durability is low. They are not suitable for abrasive plastics or large-scale production. It is most suitable for simple and basic phone case designs.

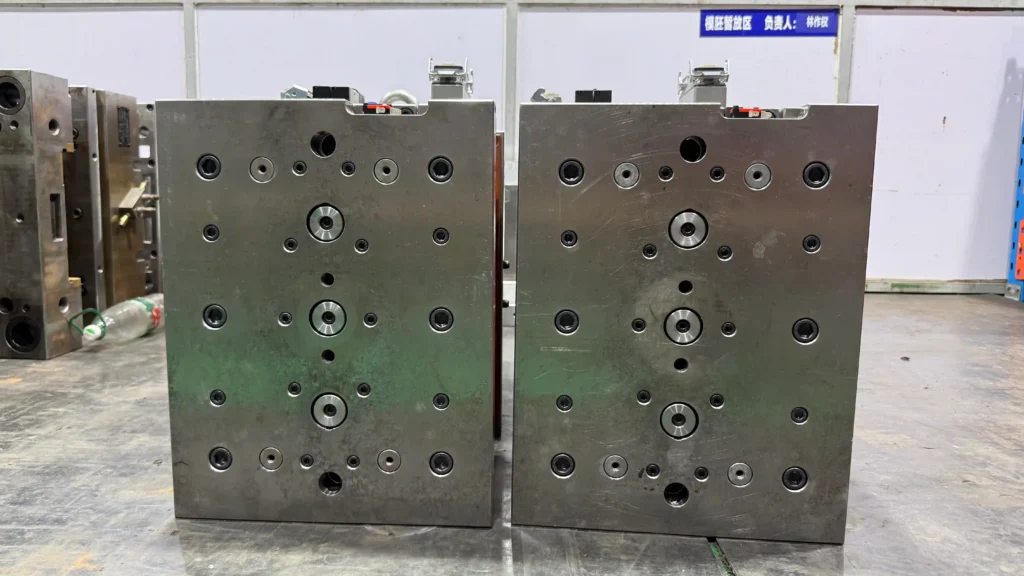

Steel injection molds: Suitable for medium to large production volumes. The durability of steel is far superior to that of other materials. Even after multiple uses, it can resist wear and tear, which makes it cost-effective in long-term production.

Steel fixtures can better handle complex designs and a wider range of plastic materials (including transparent or reinforced options). Although the initial cost of steel molds is relatively high, they reduce rework and replacement expenses over time.

The quantity of materials also affects the cost: molds used for larger mobile phone models or those with more cavities (capable of producing multiple casings simultaneously) consume more raw materials, which will increase the overall price.

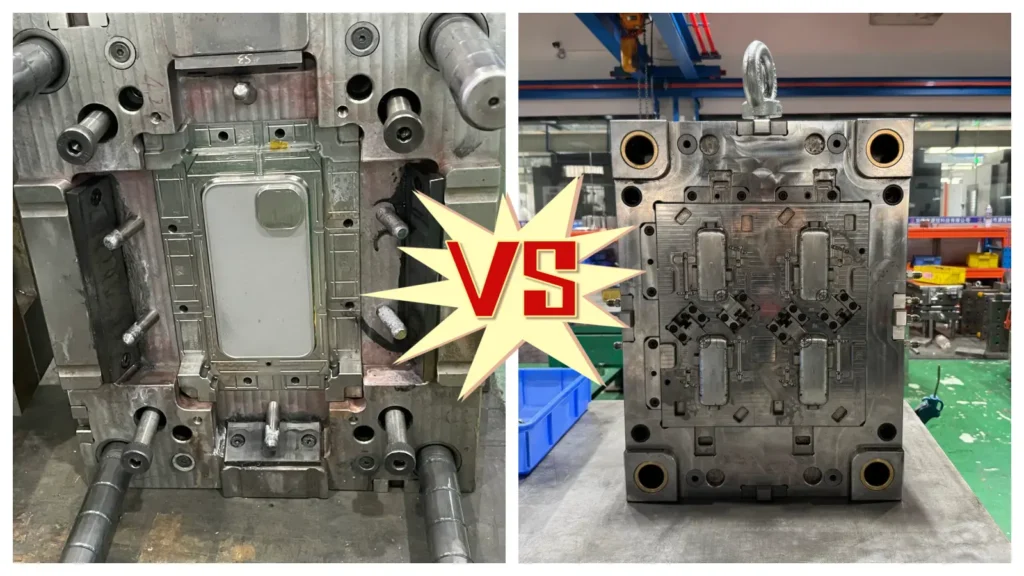

2. Injection Mold Structure & Complexity

Each design feature adds a layer of processing complexity – here’s how a specific structure affects pricing:

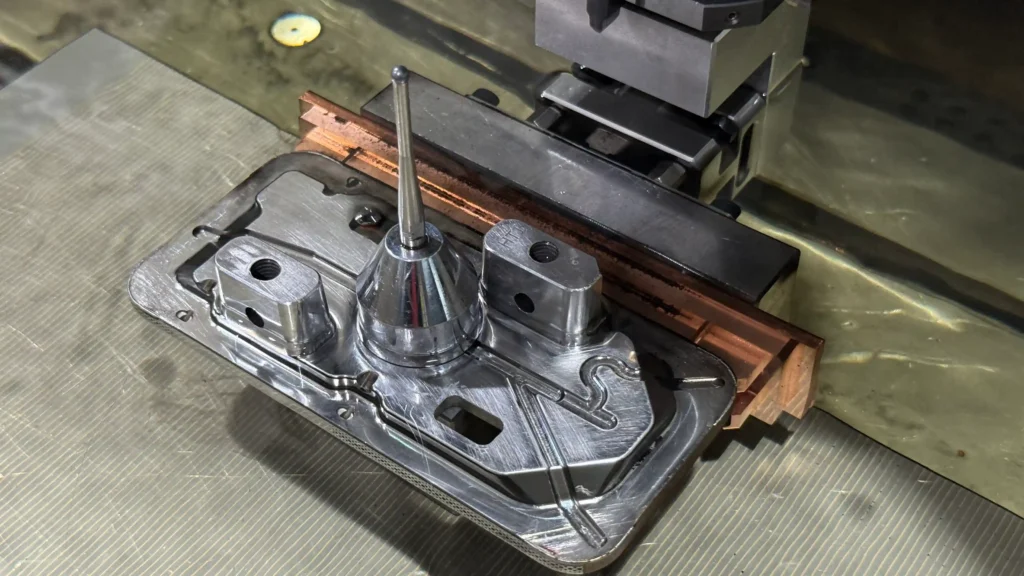

3. Processing Precision & Technical Standards

- Tolerance levels: The phone case needs to fit closely, so the injection mold must be processed in accordance with precision standards. High-end or industrial-grade shells require more stringent precision, which means that more advanced processing equipment is needed – this drives up the cost of injection molds.

- Quality control equipment: High-end mobile phone case molds need to be thoroughly inspected to ensure they meet size and appearance standards. Although this additional quality inspection will increase the cost of injection molds, it avoids more expensive production rework or customer returns in the future.

- Functional compatibility: Housings designed for wireless charging, water resistance, or other special functions require additional mold details. These details will increase the complexity of the design and thereby raise the cost.

4. Production Volume & Mold Lifespan Alignment

- Prototype/small batch: Aluminum molds or basic steel molds are the most cost-effective here. They have a relatively low upfront cost, which matches a smaller production scale – although their shorter service life is not an issue in small-batch production.

- Medium batch:

The standard steel molds have achieved a perfect balance. Their initial cost is higher than that of aluminum molds, but their durability is sufficient to handle production volume, and they do not need to be replaced frequently, thereby controlling long-term costs.

- Large batch: Although high-quality steel molds have a relatively high initial investment, their long service life means they can withstand hundreds of thousands of cycles, and their reliability can reduce downtime, saving money in mass production processes.

5. Supplier Location & Industrial Cluster Advantages

The geographical location of suppliers and their proximity to industrial clusters have a significant impact on price and quality – the following is a comparison of global choices:

Europe/America: Local suppliers offer fast delivery and strict quality standards, but their charges are much higher than those of Asian suppliers. The labor and material costs in these regions are relatively high, so the tooling cost for injection moulding here is significantly higher.

Southeast Asia (Vietnam/Thailand): Labor costs are lower than those in China, but the supply chain is underdeveloped. Although the initial mold quotation may be slightly cheaper, the longer delivery time (due to imported materials and parts) may delay production and increase hidden costs.

China’s industrial clusters (Dongguan/Shenzhen): This is the best point to balance cost and quality. As a global manufacturing center, Dongguan has the following main advantages:

- Local supply chains: Most Injection mold tooling materials and parts are purchased nearby, reducing transportation costs and delays.

- Skilled labor force: A large number of experienced mold technicians ensure precision and faster production time.

- Industry support: Government and industry resources are used to reduce manufacturing costs, thereby providing customers with more competitive prices.

YG‘s headquarters is located in Dongguan. Therefore, we take advantage of these cluster strengths to offer more favorable prices than non-cluster suppliers and faster delivery times than our Southeast Asian partners, while maintaining high quality.

Practical Tips to Control Your Phone Case Mold Costs

1. Start with DFM Analysis

2. Choose Cavity Count Based on Volume

3. Build a Long-Term Partnership with Your Supplier

FAQ

1. How much does injection mold tooling cost?

- Aluminum prototype molds (small batches): Lower upfront cost

- Standard steel molds (medium batches): Balanced initial and long-term cost

- High-quality steel molds (large batches): Higher upfront cost, lower per-unit cost over time.

Contact YG for a personalized quote, and we’ll include your free DFM analysis.

2. How much does mold modification cost?

3. Does YG offer end-to-end service?

Conclusion

The injection mold cost is mainly determined by factors such as material selection, design complexity, precision requirements, output, and the location of suppliers. By combining these factors with your needs, you can obtain high-quality molds at competitive prices.

YG combines the supply chain advantages of Dongguan with free DFM analysis to provide molds that balance cost, quality, and speed. Contact us immediately to get a free DFM report and a custom injection mold quote – let us turn your design into a profitable product.