Have you ever devoted time to designing a custom phone case but encountered obstacles during the production process – delays, unexpected costs, or quality issues that ruined your launch plan?

But what if there was a way to avoid them from the very beginning? This is where DFM(Design for Manufacturing) comes into play. If you’re wondering how to design a product for manufacturing that resonates with discerning consumers, then DFM is your ultimate solution.

What Is DFM (Design for Manufacturing)?

Table of Contents

ToggleLet’s start from the basics: DFM is a design approach that prioritizes production feasibility from day one.

Unlike the traditional “design first, manufacture later” model (which often leads to a last-minute clean-up), DFM means that your design and manufacturing processes go hand in hand. This is the core of design for reliability and manufacturability.

For phone cases, this means that the production situation in the real world must be taken into account when designing. Before completing the design, consider the performance of the material, the function of the mold, and the assembly process.

What is the ultimate goal? This phone case not only has an attractive appearance, but is also easy to mass-produce, with stable quality and high cost performance.

But why is this important to you? Because the market demands the uniqueness and reliability of products, your customers will not compromise on style and durability.

DFM Bridges this gap, ensuring that your custom design does not go off track due to production constraints.

Whether you are exploring industrial design for manufacture or refining existing concepts, DFM can keep the foundation of practicality for your project.

Key Design for Manufacturing Principles for Phone Case Manufacturing

1. Material-Matched Design

1. Material matching design (related to injection molding DFM)

Different materials have different strengths and limitations. If the pattern is too complex, the smooth leather case design may crack during the sewing process. TPU cases with sharp edges may deform during the injection molding process.

This is precisely where injection molding DFM becomes crucial. DFM means choosing (or adjusting) the design based on the material properties. For instance, optimize the thickness to provide protection, or round the corners to prevent manufacturing defects.

This also aligns with design for sustainable manufacturing by minimizing waste resulting from material mismatches.

2. Simplify Structures

Overly complex structures (such as multiple detachable parts, intricate hollowed-out designs, or non-standard shapes) will drive up mold costs and increase error rates.

Industrial design for manufacture strikes a balance between brand uniqueness and production practicality. It simplifies the structure – for example, combining two components into one – without losing your signature style.

Standardizing common elements (such as port openings or button positions) also helps to accelerate production. This complies with the proven design for manufacturing guidelines to maintain process efficiency.

3. Mold Compatibility & Production Efficiency

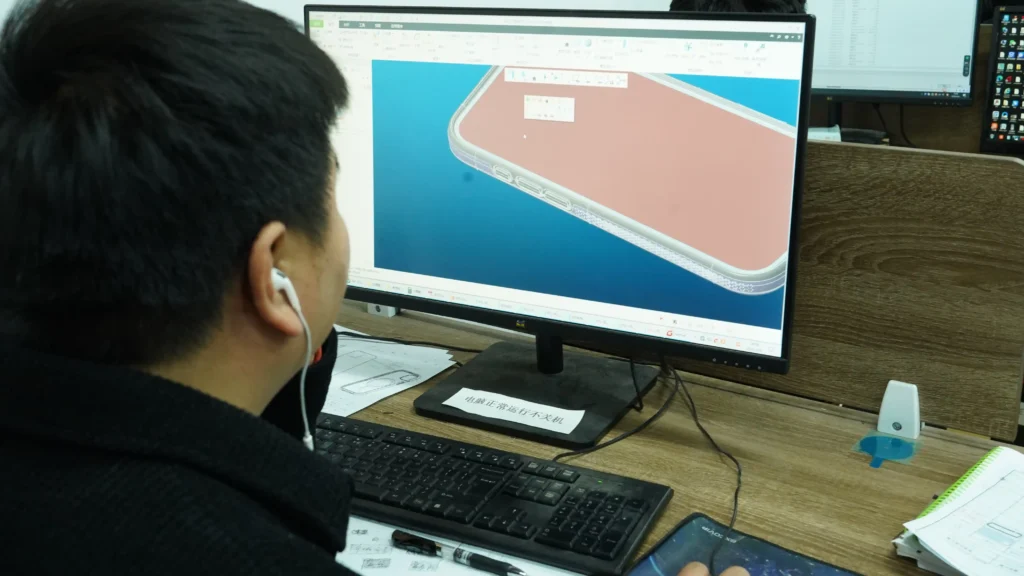

Injection molds are the cornerstone of mass production. DFM ensures that your design matches the mold’s capabilities.

Avoid overly deep cavities, easily broken thin walls, or details that cannot be uniformly injection molded. This is why injection molding DFM analysis is an uncompromising step.

It can identify mold-related bottlenecks at an early stage, ensuring that the appearance and performance of each product leaving the factory are consistent. There will no longer be any situations of inconsistent quality or production delays.

4. Cost Optimization Without Sacrificing Quality

No one wants to overpay, but cutting corners in design might backfire. DFM has found a smart way to reduce costs without sacrificing quality.

For instance, minimize material waste by adjusting the shape of the shell or reducing production steps. It also supports sustainable manufacturing design by reducing energy consumption and the use of excess materials.

For phone case brands, this means offering competitive prices while maintaining profit margins. This is a win-win situation for both your business and your customers.

The Benefits of DFM

- Slash Unexpected Costs: Remaking molds, fixing design flaws, or scrapping defective batches will take up your budget. DFM analysis can detect problems early and eliminate these costly accidents.

- Meet Tight Deadlines: The phone case market changes rapidly, and delays may mean missing seasonal trends or the release of competitors. The design that follows the manufacturing guidelines simplifies production and ensures that your orders are delivered on time every time.

- Boost Product Quality:

Consistent and defect-free phone cases build trust with your customers. DFM ensures the reliability and manufacturability of the design, so your phone case has consistent performance and is easy to expand.

- Reduce Collaboration Stress: Working with a phone case manufacturer that offers design for manufacturing services means less back-and-forth. They will point out potential problems as early as possible, offer solutions, and turn your vision into reality without giving you a headache.

How YG Implements DFM for You

As an experienced phone case manufacturer, DFM is part of our core process. Our design for manufacturing services goes beyond basic scrutiny – we tailor every optimization to your target market. Here’s how we turned it into reality:

1. Initial stage of cooperation

We won’t wait until you finish the design before joining in. In your initial consultation, we will ask about your goals, target audience, and material preferences.

This helps us mark potential production challenges in advance. This is crucial for answering the question “How to effectively design products for manufacturing” – from the very beginning.

2. DFM Expertise & Injection Molding DFM Analysis

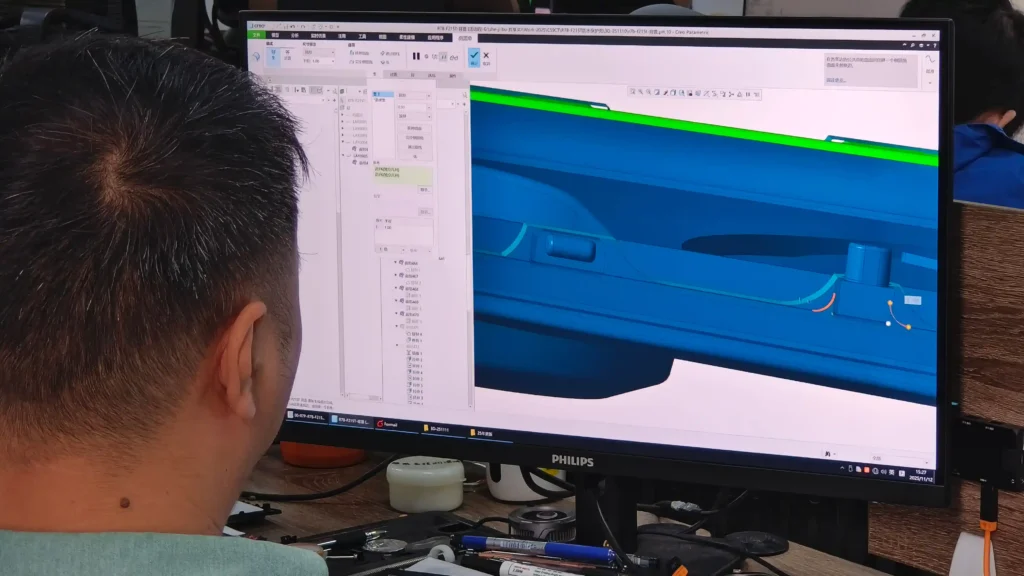

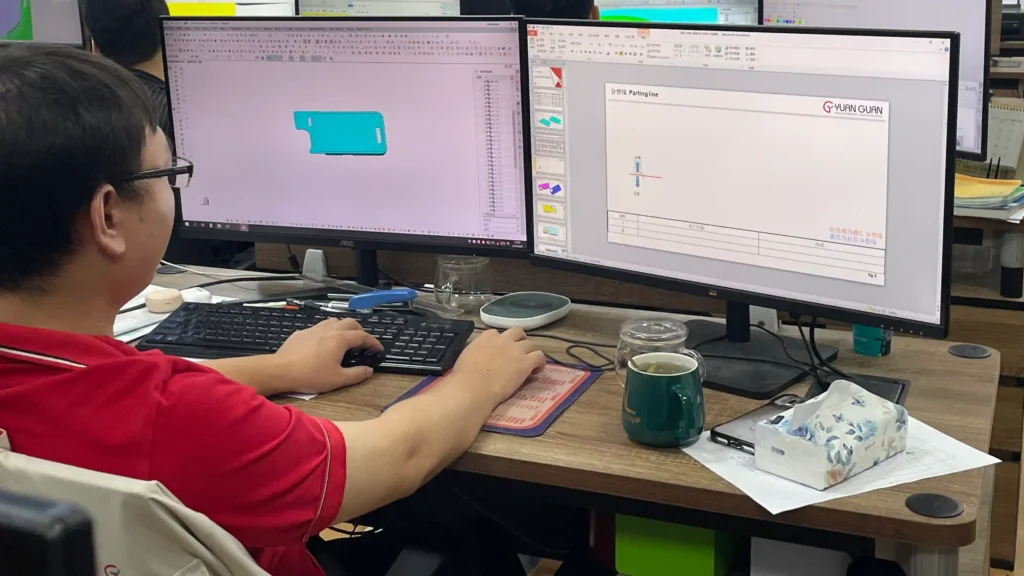

Our professional DFM engineers will conduct a thorough injection molding DFM analysis when reviewing your design documents – no matter how rough.

We will point out the areas that may cause problems (such as overly thin edges or incompatible printing technologies). We also offer actionable repairs that are consistent with manufacturing design principles.

3. Data for manufacturing instances supports design

We don’t just talk about DFM; we prove it with actual design and manufacturing examples. Take one of our European and American clients as an example: They wanted a PC phone case with a geometric shape and initially required five separate mold parts.

Using DFM, we adjusted the mode and reduced it to two parts. This reduces mold costs by 12%, increases production speed by 15%, and supports sustainable manufacturing designs by reducing material waste.

4. Sample verification

Before mass production, we will create a prototype based on your optimized design. You will test the fit, feel, and quality – to ensure it meets your expectations.

Only when you are satisfied will we expand our scale. This step eliminates the unexpected and ensures that your final product meets your vision.

How to Assess a Phone Case Manufacturer’s DFM Capabilities

Not all phone case manufacturers give priority to DFM. Working with the wrong manufacturer may ruin your project. Here’s how to determine if the manufacturer has the DFM expertise you need:

- Do they offer specialized designs for manufacturing services? Looking for a partner that offers end-to-end support, from the initial design review to injection molding DFM analysis, not just production.

- Can they share examples of design and manufacturing? Ask them about specific cases of how they used DFM to solve problems for other customers. Have they cut costs? Shorten the delivery period? “Improve quality?”

- Do they follow the guidelines designed for production? A reliable manufacturer will refer to verified design and manufacturing guidelines and explain how they can be applied to your project.

- Will they provide transparent injection molding DFM analysis? They should share the details of the injection molding DFM analysis, such as the expected yield or mold adjustment, so that you won’t be blinded.

Common DFM Mistakes to Avoid

Even with good intentions, it is easy to overlook the traps of DFM. Following verified design and manufacturing guidelines helps you avoid these:

Mistake 1: Prioritize beauty over Reliability and Manufacturability.

That thin, complex design may look great. But if it cannot withstand injection molding or drop tests, it is of no use.

Balance design style with production reality. DFM ensures that your design is both aesthetically appealing and practical for mass production.

Mistake 2: Skipping the injection DFM analysis to save time

Cutting corners in injection molding DFM analysis often leads to higher costs in the subsequent process. You may encounter mold rework, defective batches or missed delivery dates.

This is an investment that can bring about smoother production and reduce troubles. Don’t skip it.

Mistake 3: Thinking that DFM is only the responsibility of the manufacturer

You know your market and customers best. Please cooperate with the manufacturer to jointly carry out an industrial design oriented towards manufacturing.

Share insights on consumer preferences – such as expected durability or popular features. They will transform these into designs that meet DFM requirements to resonate with the audience.

Conclusion

Ultimately, the core of DFM lies in alignment. It ensures that your design vision, production capacity, and market demand operate in harmony. This enables you to deliver outstanding phone cases to consumers without the pressure of delays, cost overruns, or quality issues.

As a phone case manufacturer dedicated to your success, YG integrates design for manufacturing principles, thorough injection molding DFM analysis, and tailored design for manufacturing services into every step of our partnership. We not only manufacture your phone cases – we optimize them to help you win in the highly competitive market.

Are you ready to turn your custom phone case design into a successful production-ready outcome? Contact our team today to discuss how our DFM expertise can simplify your next project.