As an injection molding manufacturer specializing in OEM and ODM services, YG is dedicated to providing tailor-made plastic component solutions for consumer electronics brands.

Recently, we have collaborated with an innovative consumer drone brand to develop custom battery boxes for their new entry-level model, to support the production operation of their products in small batches of 1,000.

In this case, we will break down the fundamental needs of the customer, the injection molding solutions we provide, and the results of this initial cooperation. Let’s delve deeper!

Project Background

Table of Contents

ToggleOur client is an innovative consumer drone brand, dedicated to providing enthusiasts, travelers, and content creators with reasonably priced and user-friendly drones. When they launched their latest entry-level drone model, they needed a reliable injection molding factory to develop custom battery cases that met the cost-effectiveness and performance standards of their products.

After careful comparison, the customer ultimately chose YG, primarily due to our reputation for providing flexible OEM services tailored to consumer electronics brands. Their core objective is to create a lightweight and durable battery case that suits their compact drone design, while meeting the demands of small-batch production and the tight time frame for product launches.

This project presents specific challenges for consumer-grade drone applications: the battery case needs to balance affordability, portability (lightweight), and daily durability, all of which are key factors in the price-sensitive consumer market. Our injection molding factory addresses these challenges with streamlined, customer-centric solutions.

Key Requirements & Challenges

As a consumer-grade drone brand, customers’ requirements for battery boxes are closely related to the end-user experience and market competitiveness:

1. Functional performance requirements: The casing needs to be lightweight (to extend the flight time for casual use), shockproof (able to withstand accidental drops during amateur use), and its size should be perfectly suitable for the compact body of the unmanned aerial vehicle (dimensional tolerance ±0.02mm). It also requires basic dust-proof and splash protection for outdoor use (IPX3 grade).

2. Small-batch and cost targets: The customer seeks small-batch production at the first release (the first order is 1,000 pieces), and the sample delivery time is within 10 days. Cost control is crucial for maintaining the price competitiveness of products in the consumer market.

3. Industry challenge: Before collaborating with our injection molding factory, brands struggled with suppliers who either ignored small-batch orders or compromised on quality. Early attempts led to unsuitable shells (causing assembly problems), fragile materials, and long delivery times, threatening their release plans.

Custom Injection Molding Solutions from YG

1. R&D & Design Adaptation

We work closely with our clients’ product teams to ensure that the battery boxes align with the design and budget of their consumer drones.

- The wall thickness of the shell (1.0mm) has been optimized, and the ergonomic snap-on structure has been adopted, reducing the weight by 12% while maintaining the impact resistance for daily use.

- Choose cost-effective, durable ABS material with a small amount of glass fiber reinforcement to balance load-bearing capacity, lightweight performance, and wear resistance.

- Using rapid 3D prototyping to produce test samples within 3 days enables customers to quickly verify the fit and functionality, and make minor adjustments before mold development.

2. Injection Molding Process & Production Control

Our injection molding factory utilizes flexible production lines to accommodate small-batch orders without compromising on precision.

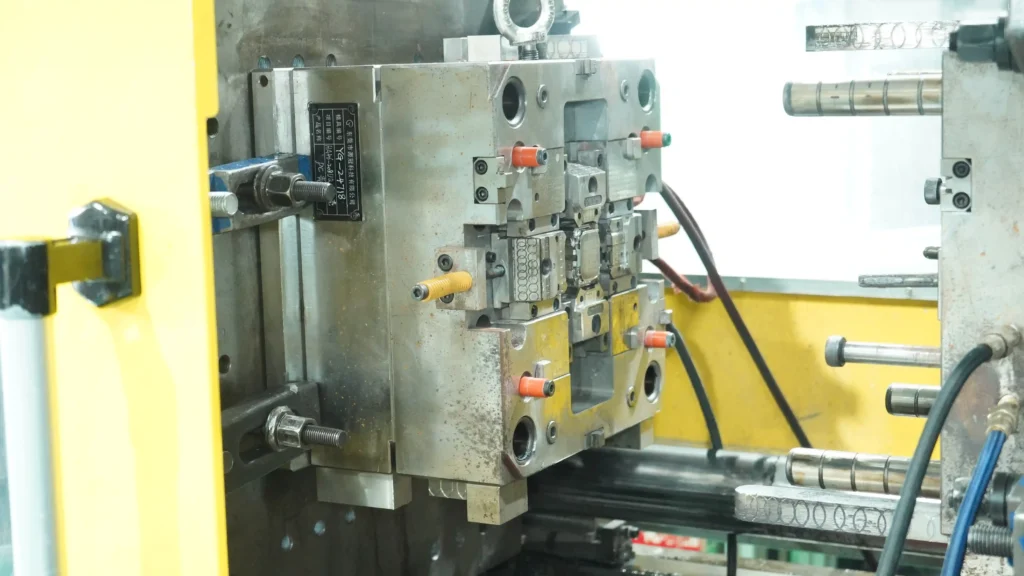

- Mold development: We have customized precision injection molds for small-batch production and optimized the cooling system to ensure consistent quality for 1,000 units. The mold maintains a critical tolerance of ±0.02mm to achieve seamless assembly.

- Flexible production: We have adopted multi-functional injection molding equipment, which can easily adapt to small-batch orders and avoid the high installation costs associated with large-scale production. Our team has simplified the workflow to minimize waste and keep costs in line with the client’s budget.

- Strict quality inspection: Each battery box has undergone multi-point testing, including size check (through precision calipers), drop test (dropping 1.2 meters on a carpet surface to simulate actual use), and visual inspection of surface defects. Our ISO 9001 certification process ensures that the qualification rate of the initial order is 99.8%.

3. Delivery & After-Sales Support

We prioritize speed and flexibility to support our clients’ product release schedules

- Accelerated delivery time: We delivered the first batch of functional samples within 7 days (3 days ahead of schedule) and completed all 1,000 orders within 2 weeks, ensuring that the customer met the release deadline.

- Specialized support: We have designated a contact person to manage the project and provide real-time updates on production progress. After delivery, we provided prompt assistance for any assembly issues and confirmed the flexibility of future order sizes.

Project Results

Our small-batch injection molding factory’s solution has provided influential results, supporting customers’ product launches and market positioning

- Product performance: The production yield rate of battery boxes is 99.8%, with zero defects for orders of 1,000 pieces. It has passed all consumer-centered durability tests and has not developed cracks or damage due to simulated daily drops.

- Customer business impact: The lightweight design has increased the flight time of the drone by 4%, which is a key selling point for consumer buyers. The customer successfully launched their new model on time, and the positive feedback from the customer highlighted the reliability and applicability of the battery.

- Basic cooperation: Our injection molding quality, flexible small-batch production capacity, and on-time delivery have left a deep impression on the customer. As their products gain market appeal, the customer has confirmed their plan to expand the order. They also discussed future cooperation in more consumer-grade drone components.

Client Testimonial

Why Choose YG?

This drone battery casing project demonstrates the consumer-centric advantages of our injection molding factory:

- Small-batch expertise: We focus on supporting new product launches and small-batch production. Our flexible process avoids high minimum order requirements.

- Cost-effective customization: We strike a balance between high-quality materials and precision molding, ensuring cost control that enables us to compete competitively in terms of both price and performance for consumer-grade products.

- Rapid response: Our streamlined R&D and production workflows ensure rapid sample delivery and order fulfillment, which is crucial for meeting the product release schedule.

- Consumer-centric quality: We design and test parts for real-world consumers, prioritizing durability, fit, and user experience.

If you are looking for an injection molding factory for OEM/ODM services, whether it’s drone battery casings, small tool casings or other plastic parts, YG Injection Molding offers flexibility and expertise. We will work with you to turn your design into high-quality and cost-effective components that resonate with consumers.

Contact us today and let’s discuss your project requirements together. Get a free quote and prototype consultation to support your next product launch!