When purchasing phone cases, you know that even the slightest deviation can undermine the product’s appeal. Have you ever stopped to consider how injection molding tolerances directly impact the quality, fit, and profitability of the phone cases you purchase?

As a reliable mobile phone case manufacturer, we have over a decade of experience in manufacturing phone cases. We will provide you with all the information you need to know about the injection molding tolerances of mobile phone cases, enabling you to make a more informed purchasing decision and avoid costly mistakes.

What Are Injection Molding Tolerances for Phone Cases?

Table of Contents

ToggleLet’s start from the basics: Injection molding tolerance refers to the allowable difference between the actual size of the manufactured phone case and its original design specifications. For phone cases, this is not merely a technical detail – it concerns the success or failure of the user experience.

Unlike ordinary injection-molded parts, phone cases need to fit closely to a specific phone model. The camera opening is 0.1 millimeters smaller, blocking the lens. The slightly curved side walls leave a gap between the case and the phone. These seemingly minor issues can turn high-potential products into returns and negative reviews.

As a high-end phone case brand, you need a phone case manufacturer that prioritizes tolerance control. Why? Because consistent tolerances mean that each casing in the batch can fit perfectly, perform reliably, and meet your customers’ high standards of the market.

Standards Injection Molding Tolerances for Phone Case

When evaluating mobile phone case manufacturers, the key is to verify whether they comply with recognized industry standards. The following are important benchmarks:

- ISO 2768: A global standard for general tolerances, typically used for plastic components such as mobile phone cases. It outlines the acceptable deviations of linear dimensions, angles, and shape tolerances to ensure compatibility across the supply chain.

- ASTM D4000: An American-focused standard that specifies the tolerance grades of plastic materials, including TPU, PC, and silicon – common materials in the production of mobile phone cases.

When it comes to phone cases, please pay attention to the following core tolerance indicators:

- Dimensional tolerance: Length, width, and thickness are typically ±0.05mm to ±0.2mm (depending on the material).

- Characteristic tolerance: The camera hole, button cut, and charging port opening require precision (±0.03mm to ±0.1mm) to avoid functional issues.

- Shape tolerance: Flatness and straightness to prevent warping and affect fit.

Does your current phone case manufacturer pre-share their tolerance compliance documents? This is a question worth asking – here, transparency means reliability.

Core Factors Affecting Plastic Injection Molding Tolerances of Phone Cases

Tolerance control is not accidental. The best phone case manufacturers master these four key factors to ensure consistency:

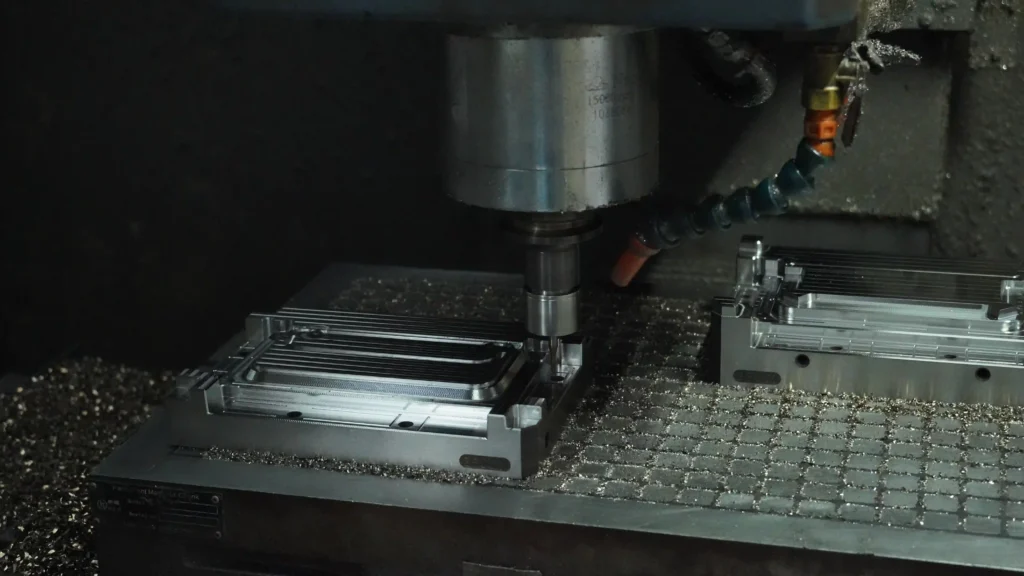

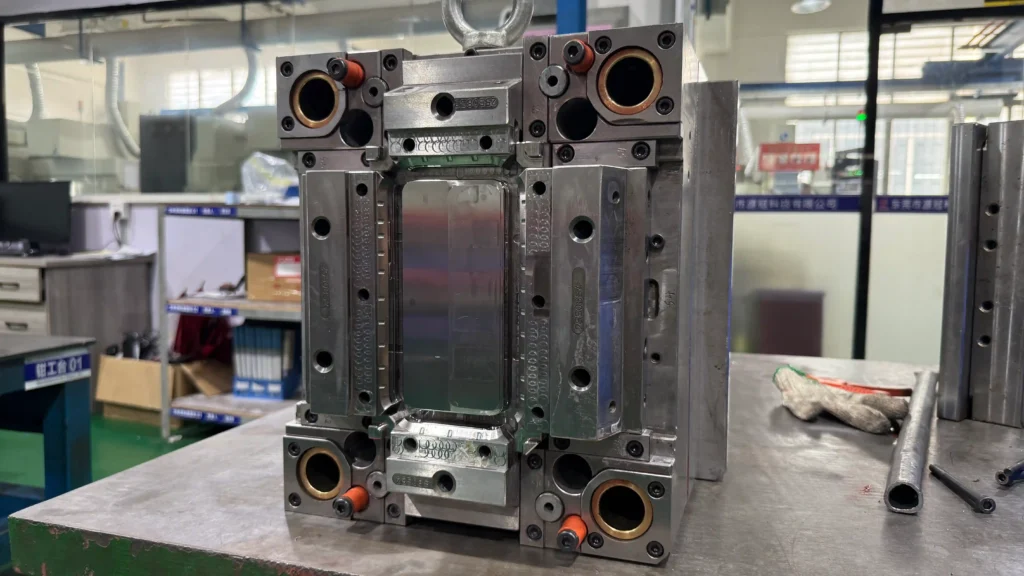

1. Mold quality: High-precision injection molds (processed by CNC technology) are the foundation of strict tolerances. Even with the best craftsmanship, poorly made molds can lead to uneven material flow and inconsistent dimensions.

2. Material properties: Each type of plastic has a unique shrinkage rate (for example, TPU shrinks by 1-2%, and PC shrinks by 0.5-1%). A skilled mobile phone case manufacturer adjusts the mold design and process parameters to make up for this.

3. Process parameters: temperature, injection pressure, cooling time, and cycle speed all have impact tolerances. Minor fluctuations here can cause dimensional deviations, so automated process control is essential.

4. Environmental conditions: Consistent workshop temperature and humidity prevent materials from expanding or contracting during production, which is crucial for consistency between batches.

When reviewing mobile phone case manufacturers, ask about their mold maintenance plans, material testing protocols, and process control systems. These details reveal the degree of importance they attach to tolerance control.

3 Critical Impacts of Tolerances on Phone Case Sourcing

For phone case brands, neglecting tolerances may lead to costly consequences. Here’s how they directly affect your business:

1. Product fit and functionality: Tolerance deviations can cause the casing to be too tight (damaging the phone during installation) or too loose (providing no protection). This will lead to customer complaints, returns, and revenue losses.

2. Brand reputation: Consumers demand high quality. If the cut on the phone case is incorrect or curved, it will not only hurt your brand but also the manufacturer.

3. Cost efficiency: Tolerance failure leads to batch rejection, delayed shipment, and rework costs. Working with a phone case manufacturer that controls tolerances can reduce these risks and keep your supply chain running smoothly.

Have you ever dealt with a phone case that failed to be shipped due to tolerance issues? This is a sense of frustration that no buyer should endure – it can be completely avoided if the right partner is found.

YG’s Tolerance Control Solutions as a Professional Phone Case Manufacturer

At YG, we take tolerance control as the cornerstone of our operations and have established our reputation as a trusted manufacturer of phone cases. Here’s how we offer consistent and high-precision phone cases:

- High-precision mold development: We use 5-axis CNC machining to process molds with an accuracy of ±0.005mm and regularly calibrate them to prevent wear.

- Specific material optimization: Our engineers test each material (TPU, PC, silicone, hybrid materials) to plot the shrinkage rate, and then adjust the process to ensure a perfect fit.

- Full-cycle quality inspection: We carry out three-step testing: First piece inspection (verifying tolerances before full-scale production), process sampling (every 50 units), and final batch inspection (100% of units are inspected with digital calipers and 3D scanners).

- Custom tolerance support: If you have unique requirements, we will work with you to design injection molds and processes that meet your needs.

Our performance record speaks for itself: We have provided tens of thousands of phone cases to our customers without any major complaints. For us, strict tolerances are not additional but standard.

FAQ

We often hear these questions from buyers of phone cases. Here is the answer you need:

1. How to verify the tolerance capability of a mobile phone case manufacturer?

ISO 2768/ASTM D4000 compliance certificate, sample test report, and recommendation letters from other customers are required.

2. What is the “reasonable” tolerance range for phone cases?

For most standard cases, the key features (cut, thickness) are ±0.1mm, and the overall dimensions are ±0.2mm. High-end phone cases may require ±0.05 millimeters.

3. Can the tolerance be customized according to my specific requirements?

Yes, if you are launching a unique design or targeting the high-end market, flexible phone case manufacturers will adjust the tolerances to meet your requirements.

4. How do you ensure the consistency of tolerances in mass production?

Automated process control, regular mold inspection, and statistical process analysis (SPC) help us maintain consistency, even for orders of over 100,000 units.

Conclusion

When purchasing mobile phone cases for the market, injection molding tolerances are non-negotiable. They directly affect product quality, customer satisfaction, and your bottom line. The key to success lies in cooperating with mobile phone case manufacturers, who not only need to “meet” the tolerance standards but also be proficient in them.

At YG, we understand the unique needs of our clients. Our strict tolerance control process, in compliance with global standards and committed to transparency, makes us a reliable partner for your phone case procurement needs.

Are you ready to purchase high-precision phone cases to meet your tolerance requirements and please your customers? Please contact us immediately to discuss your project, request samples, or learn more about our manufacturing capabilities.