Have you ever struggled with the challenges of product design, such as combining soft and hard materials or adding colors without additional assembly? Suppose you are manufacturing items such as phone cases, auto parts, or medical devices. In that case, you know the troubles of multi-step manufacturing: forming, bonding, or welding separately not only consumes time and money, but also may lead to weak bonding failures over time.

Fortunately, there is a solution that can simplify this process while enhancing durability -two-shot injection molding. Let’s analyze what this technology is, why it is important, and how it is changing products like phone cases.

What Is Two-Shot Injection Molding, Exactly?

Table of Contents

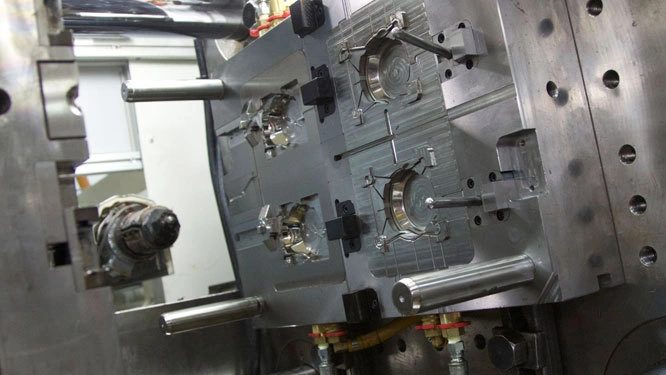

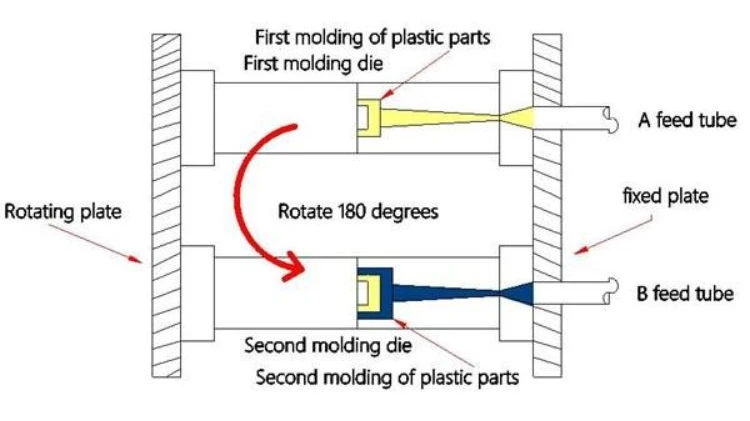

Toggle- First shot: This process begins just like a traditional injection molding. A liquid polymer (for example, hard PC plastic used for the scratch-resistant back of mobile phone cases) is injected into the mold cavity. It will cool down slightly – but not solidify completely – so it is still easy to bond.

- Mold transfer: The partially cured first component is automatically (or by robot) moved to the second mold cavity. For phone cases, the shape of this cavity is designed to add soft TPU plastic around the edges (for grip and drop protection).

- Second shot: The second material (in our case, TPU) is injected into the new mold. When it cools down, it forms molecular bonds with the first material – no glue, no seams, no weaknesses.

- Final product: The final product is a phone case where the hard back and soft edges are integrated, eliminating the risk of peeling and requiring no additional assembly, making it look cleaner.

Benefits of Two-Shot Injection Molding

1. Reduced Manufacturing Costs

- No extra labor to attach soft TPU edges to hard PC backs.

- No need for additional tools or adhesives (which add both cost and supply chain complexity).

- Reduce production errors that lead to rework or scrapping (such as misaligned edges or failed glue bonding).

Over time, these savings add up – especially for bulk orders, even small unit cost cuts will increase profit margins.

2. Enhanced Durability & Quality

- There will no longer be “edge peeling” (a common complaint about boxes stuck together).

- Better resistance to frequent wear and tear, such as drops or scratches (because the two materials complement each other – TPU absorbs impact and PC resists scratches).

- The quality of each unit is consistent: Unlike manual assembly, the automated two-step process ensures that each phone case has the same bonding strength and fit.

3. Minimal Waste & Better Sustainability

- Use precision molds to minimize excess plastic as much as possible.

- Reduce the waste caused by assembly failures (as there is no need to separate and rework parts).

This not only reduces material costs, but also meets the growing demand for sustainable manufacturing – an important factor for both brands and consumers.

4. Faster Time-to-Market

- You can go from design approval to mass production within a few weeks instead of months.

- Before assembly, there is no need to wait for individual components to take shape and be dispatched.

This is crucial for maintaining a leading position in a fast-paced market.

The Application of Two-Shot Injection Molding

1. Phone Cases

- Dual-material protection: Combining TPU (soft, shock-absorbing) and PC (hard, scratch-resistant), it provides all-round drop protection.

- Ergonomic design: Increase softness and grip with TPU to prevent sliding while maintaining a rigid and smooth appearance on the back.

- Custom style: Embed two colors (for example, a matte black back with a smooth white logo) or texture (for example, a dot-like grip area on a smooth shell) without printing (fading over time).

2. Automotive Components

3. Medical Devices

4. Tools & Household Items

Two-Shot Injection Molding vs. Overmolding: Which Is Right for You?

FAQ: Two-Shot Molding for Phone Case Manufacturers & Brands

If you’re considering two-shot molding for your phone case line, here are answers to the most common questions:

Q: Do I need a huge order to use two-shot molding for phone cases?

A: Not necessarily. Although bulk ordering can maximize cost savings, many manufacturers (including professional phone case manufacturers) offer flexible minimum order quantities (MOQs) – usually starting from 3,000 to 5,000 standard designs. The minimum order quantity for custom designs may be slightly higher, but they are still feasible for growing brands.

Q: What materials work best for two-shot phone cases?

A: The most popular ones are TPU (soft and elastic) and PC (hard and rigid), which are ideal choices that balance protection and fashion. You can also use ABS plastic (for durability) and TPE (for softness), or even the same material in two colors (for example, transparent PC and opaque PC for “window” design).

Conclution

Whether you are a phone case manufacturer looking to upgrade your product line or a brand aiming to create more durable and fashionable products, two-shot injection molding offers a clear path to improve quality, reduce costs, and accelerate release speed.

As an experienced partner in the plastic manufacturing field, YG has professional knowledge in the 2K injection molding of mobile phone cases and other products. We can help you turn your design concepts into reality. From material selection to injection mold making and mass production, we will guide you through every step.

For more information or to obtain a free quote for your 2-shot injection molding project (including phone cases), please contact us immediately.

Note: All production processes comply with industry quality standards, including material safety certifications (such as ROHS), to ensure that your products are safe for consumers worldwide.