For phone case buyers, injection molding flash is not just a minor defect – it directly affects the return rate, brand reputation, and profitability. This guide will clarify what flash is, why it emerged, and how to address it, while focusing on actionable, buyer-centered solutions.

What Is Flash in Injection Molding?

Table of Contents

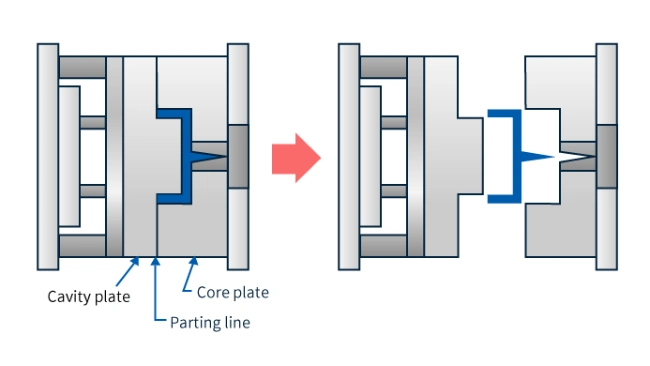

ToggleInjection molding flash refers to the situation during the production process where excess plastic seeps out from the mold gaps and solidifies onto the final phone case, damaging both functionality and aesthetics. Its appearance varies depending on the material

- TPU soft cases: Thin and fine “hair” along the edge or cut.

- PC hard cases: Sharp, fragile “spurs” around the camera hole or button slot.

- Silicone cases: Soft and saggy, with raised edges like ruffles, which damages the fit.

The acceptable industry standard for flash is less than 0.004 inches (0.10 millimeters) – thin enough that no faults will be detected when a finger is moved along the edge of the casing. High-end buyers (such as luxury mobile phone accessory brands) usually require flash to be as thin as 0.002 inches (0.05 millimeters).

To quickly assess the flash in shipment: Hold the cases in bright light, check the parting line (where the two halves of the mold meet), and move your fingers along the edge. Visible obstacles indicate the flash that needs to be addressed.

5 Common Causes of Injection Molding Flash

1. Parting Line Mismatch

The parting line is the seam where the two halves of the mold are clamped together. The misalignment or gap here will cause the plastic to leak. Common triggering factors include:

- Mold wear: After over 10,000 cycles, the plastic injection mold surface deteriorates, creating gaps (e.g., the client’s TPU housing flash, which is repaired by re-grinding the mold’s parting line to close a 0.03mm gap).

- Debris accumulation: Plastic shavings, dust, or coolant residue can cause the mold to not close tightly (a European customer’s PC case had single-sided flashing due to plastic debris).

- Poor mold design: In complex situations (for example, those with built-in brackets), precise parting lines are required – misaligned lines cause gaps caused by pressure.

Buyers should verify whether the phone case supplier uses the “spot method” (applying ink on half of the mold to check for alignment) in order to detect any mismatches as early as possible.

2. Inadequate Venting

When plastic fills the cavity, the injection mold needs vents to release the trapped air. Poor ventilation can generate pressure, forcing the plastic through the gaps. The main problems include:

- There is a lack of ventilation openings close to tight features (such as camera holes or charging ports).

- Incorrect vent spacing (>2 inches) or size (too small for the material: TPU requires 0.001-inch vents, PC requires 0.002-inch vents).

3. Insufficient Clamping Pressure

During the injection process, the clamping pressure makes the mold semi-closed. Too little pressure can cause the neatly arranged injection molds to slightly separate. The correct pressure follows the formula that the supplier must calculate:

clamping force = projected area of the phone case × injection pressure × 1.2 (safety factor)

Suppliers often apply a “one-size-fits-all” pressure (for example, applying the same force to thin TPU and thick PC casings), resulting in flashing. Buyers should request that the pressure calculation be tailored to their design.

4. Low Plastic Viscosity

The viscosity (fluidity) of molten plastic determines the risk of leakage. Low-viscosity (liquid plastic) leaks from the gaps for the following reasons:

- The temperature is too high (for example, heating TPU above 220℃).

- Wet materials (moisture in silicone resin or PC reduces viscosity – drying TPU at 100°C for 2 hours solves a customer’s flash problem).

- The material grade is incorrect (general-purpose plastic and plastic specifically designed for mobile phone cases).

5. Wear of Gate Bushing

How to Fix Flash Injection Molding

| Deflashing Method | Best For | Pros | Cons |

|---|---|---|---|

| Manual Trimming | Small batches (≤500 units) | Low cost, precise for delicate cases | Labor-intensive; risk of scratching |

| Cryogenic Deflashing | Medium batches (500–5,000) | Fast (1 unit/minute); no damage | High equipment cost for small orders |

| Ultrasonic Deflashing | Large batches (≥5,000) | Automated; consistent results | Upfront investment required |

How to Avoid Flash in Injection Molding

1. Pre-Production: DFM Analysis & Mold Testing

- DFM (Design for Manufacturability) Checks: Software simulates injection molding to detect flash risks (for example, tight cuts that require vents).

- Mold Validation: For each mold, the sampling method is adopted to produce 50 to 100 sample boxes to verify that the flash complies with the standard of less than 0.004 inches.

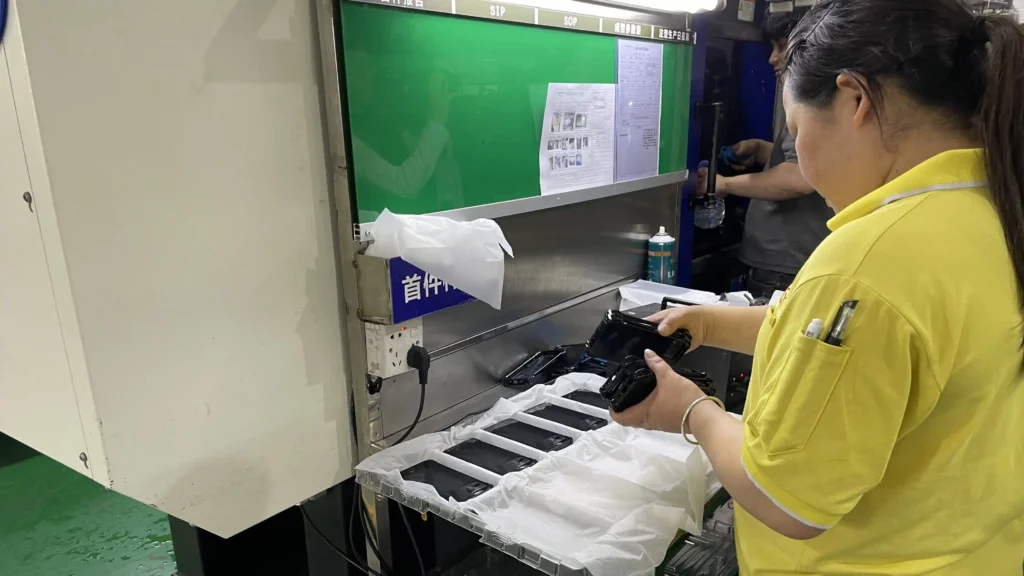

2. In-Production: Double Inspections

- First item inspection: Each shift starts with 10 boxes of flash testing (light + finger inspection).

- Parameter recording: Temperature, pressure, and material moisture content are tracked to detect deviations as early as possible.

- Mid-production sampling: 1% of cases are inspected – if flash is detected, production is suspended.

3. Post-Production: Feedback Loops

Ready to Eliminate Injection Molding Flash

Flash can pose risks to profits and brand reputation, but this can be avoided if the right supplier is chosen. YG combines over 10 years of experience with European/American buyers and a case-verification process to offer Flash-free phone case services.

The next step:

Share your case design to get a free DFM analysis to identify Flash risks.

Contact YG today – we’ll get back within 24 hours.