Introduction

Table of Contents

ToggleAs a clear phone case manufacturer, YG understands the growing demand for high-performance, reasonably priced, and aesthetically flawless transparent cell phone cases. Brands in both the United States and Europe are facing a dilemma: how to strike a balance between military-grade drop protection, anti-yellowing clarity, and low-cost small-batch production. Here is our solution.

The Problem: Why do many transparent phone cases fail

- Pure PC or TPU designs have low durability

- Hard PC phone cases are prone to cracking upon impact, while ordinary TPU phone cases will turn yellow within a few months.

- Customer demand: A PC and TPU hybrid phone case that lasts 2+ years without yellowing.

- Expensive customization for small brands

- The traditional double-shot molding is expensive and only suitable for mass production of a single model. An order of 1,000 units is not profitable.

- Mobile phone case surface fingerprint, oil problem

- Standard PC phone case material absorbs oil and is prone to fingerprint adhesion, so they need to be cleaned every day.

YG’s Solution: Innovative Design of Hybrid Materials

Why Choose a PC + TPU Hybrid?

- PC Backplate (2.0mm): Provides crystal-clear transparency and scratch resistance to the back of the phone case.

- TPU Bumper (2.0mm): High elastic material frame design absorbs 90% of impact energy (test 1.8m drop).

PC + TPU hybrid design combines the advantages of the two materials at the same time, and avoids the problem that a hard PC phone case is easy to break when disassembled and assembled.

Is there a risk of yellowing for TPU? YG’s anti-yellowing TPU can effectively prevent the yellowing of transparent phone case frames through advanced material science and phone case manufacturing processes.

Core Innovation 1: IML Technology for Anti-Fingerprint Surfaces

Through IML technology will double the processed PET film on the PC back. Effect: The fingerprints are 85% less than those of a standard PC case.

We add a hardening coating on one side of the PET film to further enhance the surface hardness and scratch resistance of the phone case. One side is coated with AF, providing a smoother touch and anti-fingerprint effect.

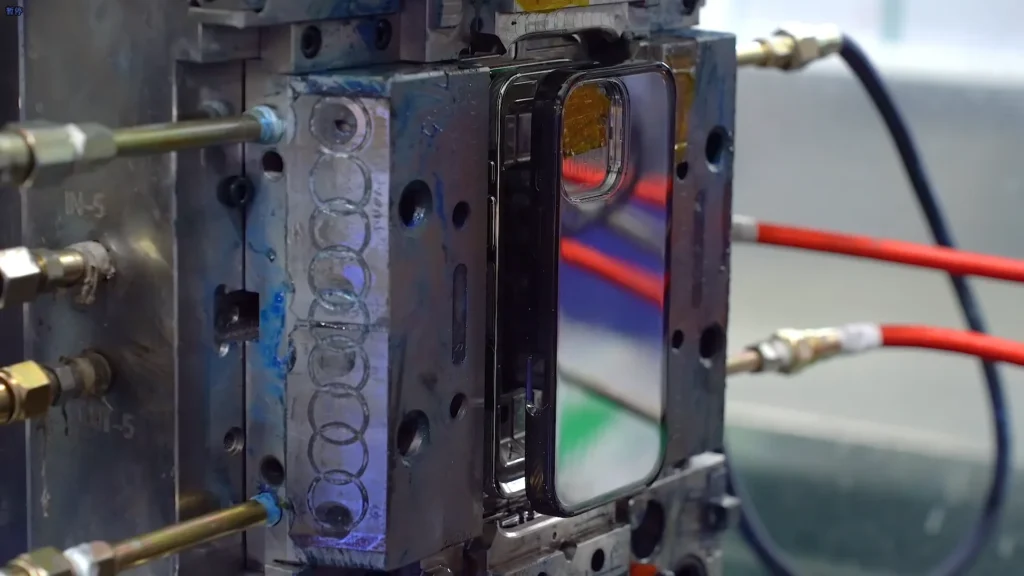

Core Innovation 2: Insert Molding for Cost Efficiency

- What is insert molding? This is a process of placing prefabricated parts (such as PC backplanes) into molds and injecting molten TPU around them.

- The advantages of YG: The cost of single-mold production is 30% lower than that of dual-mold production.

→ Ideal orders of 1,000 to 5,000 units with a delivery time of 15 days.

Core Production Steps:

Stage 1: Fabrication of the IML-Bonded PC backplane

- UV-treated PET film + 2.0mm PC sheet → 150°C thermal fusion.

- By injection molding equipment and PC back to take out by the automation of mechanical arm, by a quality engineer to check back again, with thin film to prevent from dust.

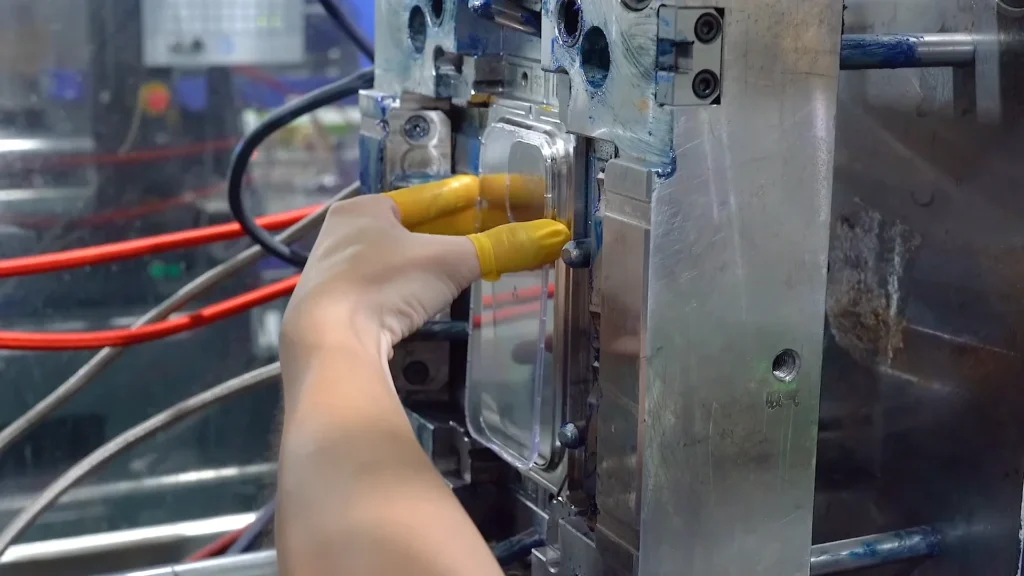

Stage 2: TPU Bumper Integration via Insert Molding

- Place PC backplate into mold → Inject 215°C liquid TPU → Cool for 45 seconds.

Stage 3: Post-process and quality control

- Deburring: Remove 0.05mm excess material for seamless edges.

- Rigorous testing: 5,000+ abrasion cycles, 72-hour UV exposure, and 1.8m multi-angle drops.

Results: Metrics That Matter to Brands

- 92% Light Transmittance (vs. 85% industry average).

- 0.28% Defect Rate (ISO 9001-certified production).

- 22% Lower Production Costs per unit than dual-material methods.

Client Testimonial

“YG’s PC and TPU hybrid phone case gave us a 40% cost reduction for 1,000-unit orders. The insert molding solutions are perfect for startups!”

— David R., Founder of UrbanGear (U.S. Accessories Brand)

Why Partner With YG?

- Flexibility of small orders

- The MOQ is 1000 pieces, and the samples can be turned around within 72 hours.

- Top-quality phone case materials

- Medical-grade PC phone case material + anti-yellowing TPU. Provide the best TPU and pc hybrid phone case.

- End-to-End Service

- We offer ODM solutions and provide one-stop services from design to delivery.

Start your project today. Get your free quote →

.webp)