As a leading silicone Apple Watch band manufacturer, YG has collaborated with an American health technology startup to address a crucial challenge: creating a comfortable silicone watch band for the Apple Watch that users can wear while sleeping. The customer requires custom Apple Watch bands that combine medical-grade safety, breathability, and rapid mass production.

Due to skin irritation, over 80% of users have abandoned wearable devices. YG’s expertise in LSR technology enables us to offer breakthrough solutions.

The Challenge: Balancing Safety, Comfort, and Speed

Table of Contents

ToggleThe client’s requirements were clear but complex:

- Customer safety requirements require us to provide hypoallergenic materials that can meet FDA/REACH standards for prolonged skin contact.

- Traditional silicone bracelets often have poor air permeability, which requires us to provide a sleep optimization design: eliminate pressure points and ensure air permeability, ensuring comfort during night use.

- Due to the tight production schedule, speed is of vital importance. An excessively long delivery time may cause the customer to miss the product launch window. It is necessary to accelerate the completion of delivery without sacrificing quality.

YG’s Solutions: Precision Engineering for Unmatched Performance

1. Co-Creation Design Process: From Concept to Wearable Innovation

Our engineers work closely with clients to transform vague ideas into achievable designs.

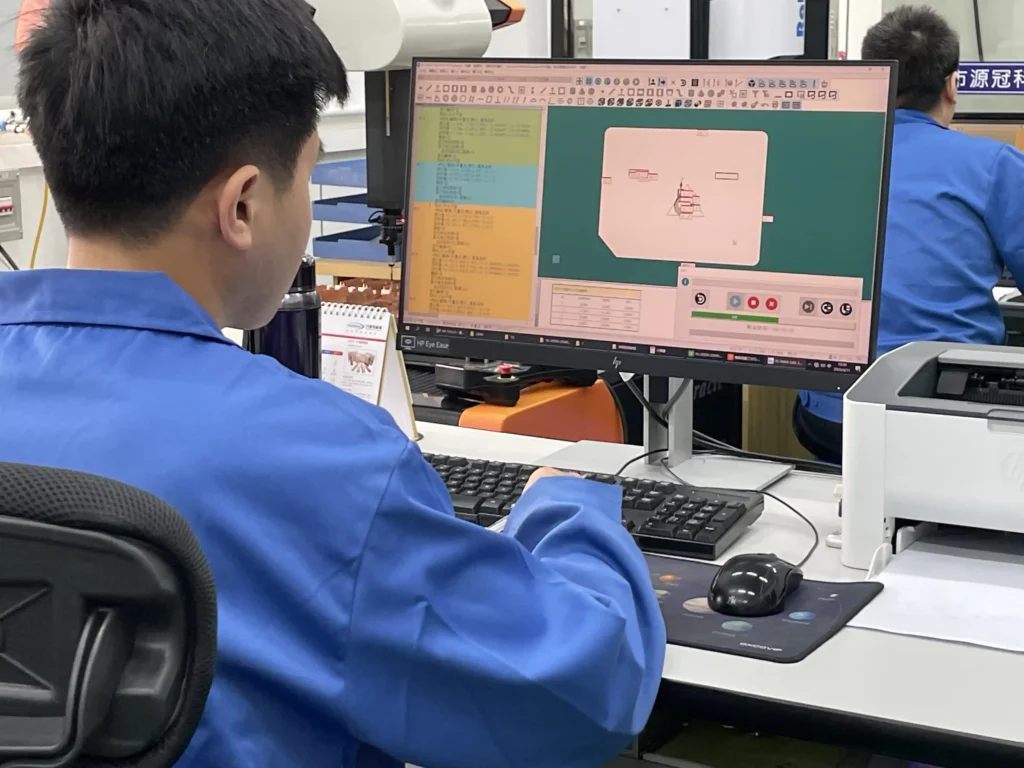

In response to the client’s demands for safety and comfort, our engineering team uses CAD software to provide realistic design drawings and renderings. Through strict design reviews, we offer DFM reports to ensure the manufacturability of the design and avoid potential production issues.

Result: Five design iterations were completed within 10 days, and the 3d printed prototype was dispatched within 72 hours.

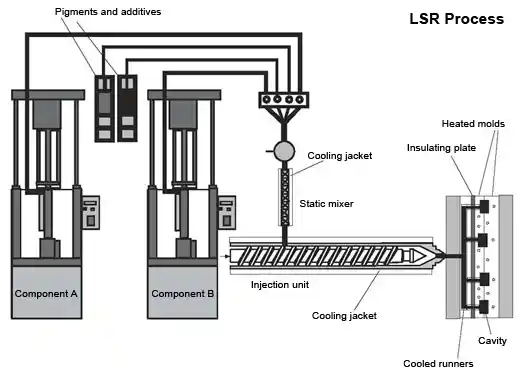

2. Use Medical Grade Silicone Material and LSR Technology

As a top supplier of silicone Apple Watch bands, YG prioritizes biocompatibility.

By relying on a strong material supply chain network, we select LIM liquid silicone (Shore 15A hardness) that meets FDA standards, featuring skin-like softness and durability.

In terms of the manufacturing process, LSR technology is adopted. Platinum is used as the catalyst for vulcanization of liquid silicone rubber to solidify the silicone rubber and form it, eliminating toxic by-products.

After strict allergen testing, the incidence of dermatitis reached 0.3% (5% in the industry).

This approach establishes YG as the best Apple Watch band for sleeping in safety benchmarks.

3. Rapid Production: Speed that does not Perfunctorily Focus on Quality

We have over 130 injection molding machines, ensuring an unparalleled production speed for Apple watch silicone bands.

Through advanced injection molding equipment and process technology, as well as experienced engineers, we can achieve efficient production of silicone apple watch bands.

We assemble over 30,000 sets of finished products per day and have passed the ISO 13485 quality management system certification.

Customer benefit: A $120,000 penalty for delayed release was avoided.

4. High-Precision Molds Ensure the Consistency of Product Batches

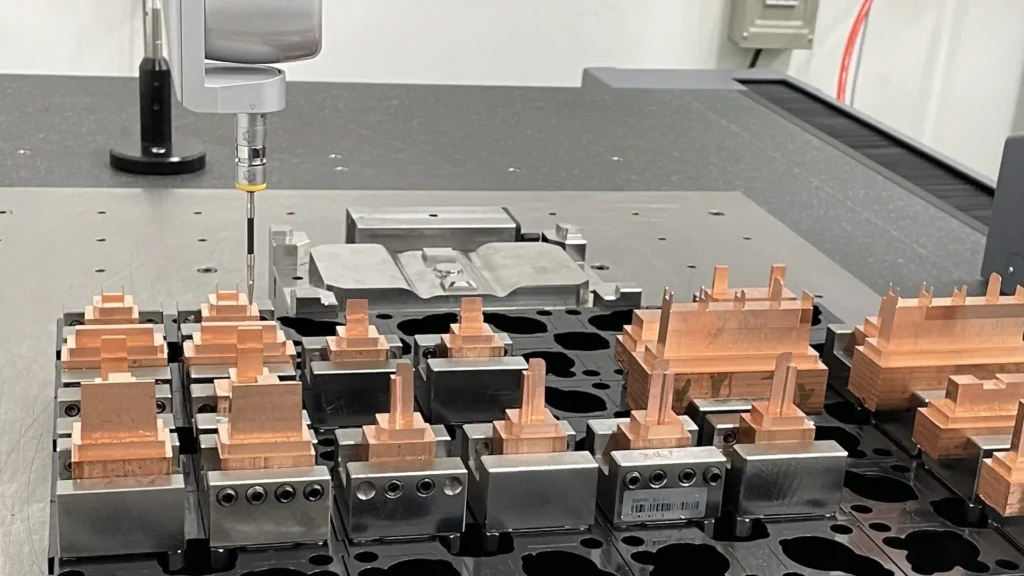

Starting from mold making, advanced 5-axis CNC machining equipment is used to manufacture high-precision molds.

Through the detection of the three-dimensional projector, it is ensured that the precision snap is within the design tolerance, and whether the surface deviation affects the wearing comfort is detected. Ensure the most comfortable sleep with Apple Watch bands.

The pressure test tape was subjected to over 5000 tensile cycles and 60°C sweat simulation.

The defect rate is 0.29%, which is 7 times lower than the industry average.

Results: Launch the Listed Products Within the Prescribed Time

| Metric | YG’s Performance | Industry Standard |

|---|---|---|

| Development Timeline | 35 days (Design to SOP) | 90+ days |

| User Comfort Score | 4.8/5 (Sleep Comfort) | 3.5/5 |

| Order Fulfillment | 15 days (30K units) | 30-45 days |

The customer’s product became a best-selling item on Amazon’s “Best Sleep Apple Watch Bracelet” within three months, with a repeat purchase rate of 40%.

Client Testimonial

“YG has transformed our vision into a leading product in the category. The silicone watch bands for Apple Watch exceeded our durability test, and the 15-day turnaround time changed the game. We have now collaborated with them on six custom series.”

— CTO, SleepWell Technologies (California)

Why Choose YG as Your Apple Watch Band Manufacturer?

- End-to-end expertise: ODM solutions from custom Apple Watch bands design to FDA-compliant manufacturing.

- Verified speed: 72-hour prototype production speed, and mass production time reduced to 15 days.

- Strong R&D capabilities: 80 patents and over 100 R&D personnel will turn your vision into reality.

Contact YG to discuss your silicone Apple Watch strap project now!