When the German outdoor equipment importer required IP68 waterproof Airtag cases, YG successfully delivered them. As a certified Airtag case manufacturer, we combine professional waterproof verification with signal optimization design—zero returns within 6 months. Learn how we address actual production challenges.

Challenge: The 3 Questions You Care About Most When Purchasing Waterproof Airtag Bags

Table of Contents

ToggleIt is not easy to find a reliable manufacturer of waterproof Airtag cases. Our German partners are facing these real obstacles:

- Failed waterproof claims from past suppliers

- Minimum Order quantity (MOQ) is more than 3,000 pieces

- Signals interfere with Apple’s Find My network

You need practical and feasible solutions, not just empty slogans.

YG’s Airtag Cases waterproof verification solution

1. Waterproofing technology and materials

We use LIM injection molding technology and liquid silicone rubber vulcanized with platinum catalysis. It has high fluidity, rapid vulcanization, is non-toxic and environmentally friendly, and has natural water resistance.

The Airtag cases produced by the LIM process have high precision and a short production cycle, ensuring seamless molding of the products and reducing the chance of water seepage from the source.

2. Verification of waterproof testing equipment

In the production process, we verify the waterproof function of the AirTag case for you through the following 4 major inspection items:

- Sealing performance test: Birefringence measuring instrument, Simulate the water pressure environment to test the compressive strength and sealing integrity at the case joints.

- Material durability test: Using Alcohol resistance, rub the surface repeatedly to verify the anti-wear performance of the waterproof coating.

- Environmental adaptability test: Through a Programmable temperature & humidity chamber, conduct high and low temperature cycling tests (such as -20℃ to 60℃) to examine the waterproof stability of the material under thermal expansion and contraction.

- Structural strength test: Tensile tester, stretch the interface part of the case to evaluate the product’s anti-deformation ability.

Before the AirTag case leaves the factory, we will also entrust the laboratory to conduct the IPX waterproof grade certification to ensure the reliability of the waterproof function. So far, YG has passed the tests of more than 1,000 third-party laboratories.

Third-party laboratory testing

3. Strict Quality Control System Guarantee

- Mold accuracy inspection: During the mold-making process, three-dimensional detectors and 2.5D detectors (with precision reaching the micrometer level) are used to monitor the mold’s accuracy to ensure there are no structural defects.

Automated quality control: We can automatically detect the uniformity of the waterproof coating and avoid the pores of the waterproof film through the visual oiling machine.

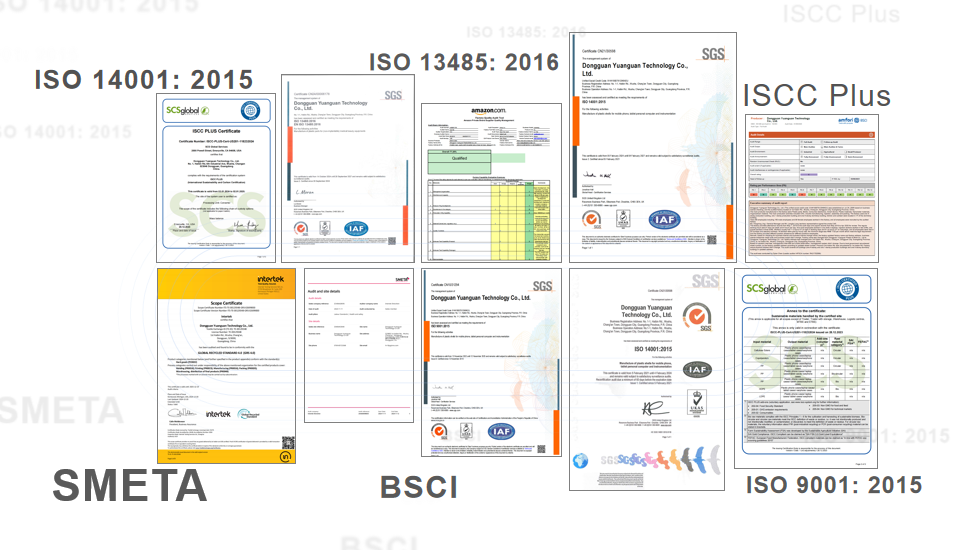

- Certification Management: Through ISO 9001, BSCI (Walmart/Amazon factory inspection standard), SMETA, and other system certifications, to ensure the standardization of the production process.

certification

Flexible production: Order 500 waterproof airtag cases instead of 5,000

YG’s MUD mold technology reduces the obstacle to the minimum order quantity. The Master Unit Die system is adopted. When changing colors, there is no need to disassemble the entire mold. Cleaning and color switching can be completed within 30 minutes.

It reduces downtime by 70% and is highly suitable for small orders in multiple color batches. In this way, you can control inventory costs and gradually increase orders.

Mold

3. Ensure signal performance: Find my things underwater

The attenuation of all test signals was maintained below 0.4 dB.

Our patented exhaust design prevents interference.

Test your samples with actual AirTags before shipment.

Cooperative Journey: From Prototype to 10,000 Sets

Phase One: Risk-free sampling

We delivered three versions for field tests.

You can get the 3d printed prototype within seven days.

Phase Two: Adjustment and mold making

The fixed ultrasonic welding gap is 0.05mm.

Custom hooks have been added according to the customer’s requirements.

The color accuracy reaches Delta E≤1.5 (Pantone verification).

Phase Three: Mass Production

More than 130 injection molding machines are in operation around the clock, and over 50 quality inspection teams ensure product quality

Every 100 units undergo a 72-hour stress test.

We coordinate logistics and transportation arrangements to ensure the timely and safe delivery of your products

Result: Why does This Become Their Best Waterproof AirTag case

The tangible achievements of the client:

- 0% return rate within 6 months (Amazon DE)

- MOQ has decreased by 83% (from 3,000 to 500).

- 20% faster shelf-readiness vs. competitors

Client Feedback:

“YG’s live factory feed showed exact plastic temperatures during molding. That transparency made us switch manufacturers.”

Your Next Steps with a Certified Waterproof Airtag Case Manufacturer

YG helps you avoid 3 critical mistakes:

- “How deep is AirTag waterproof?” → We simulate 2m/72-hr environments.

- “Will cases block signals?” → We test with Find My active.

- “Can I order small batches?” → MOQ starts at 500.