Introduction

Table of Contents

ToggleEvery 3 in 5 European electronics brands struggle with custom AirPods case production. When Nordic Audio Gear needed eco-friendly wireless charging cases, they faced:

- 8-week design delays

- $15k mold costs

- Failed REACH compliance tests

YG’s AirPods case manufacturing solutions cut development time by 60.7% while ensuring regulatory compliance. This case study reveals how technical innovations help brands overcome production bottlenecks.

Challenge 1: Slow Design Iterations

Most manufacturers take 8 weeks for 3D modeling and prototyping. YG’s 72-hour prototype delivery combines:

- 3D printing for visual verification

- CNC machining for functional testing

- Virtual drop simulations (MIL-STD-810G standard)

“Our previous supplier needed 2 months for simple tweaks. YG delivered 3 design options in 72 hours,” says Nordic’s Product Manager.

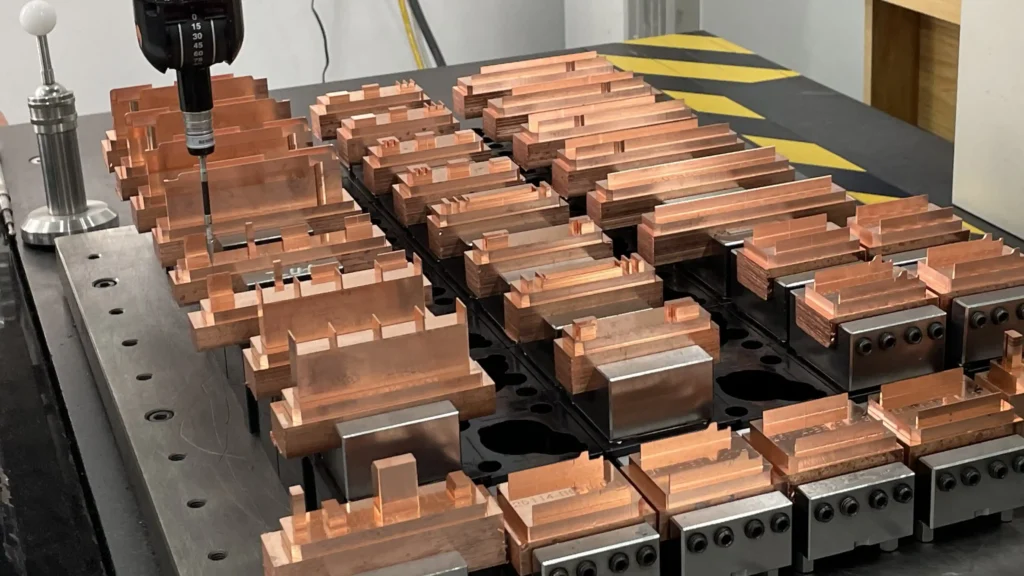

Challenge 2: High Tooling Costs

Traditional mold making costs 8,000−8,000−20,000. YG’s MUD technology reduces expenses by 40% through:

🔹 Modular mold components

🔹 Rapid insert replacement

🔹 0.005mm precision machining

This enables 500-piece MOQ orders – 20x more flexible than industry averages. Brands can test niche designs risk-free.

Challenge 3: Compliance Failures

62% of AirPods case recalls stem from material issues. YG’s 3-stage quality control guarantees:

- FDA-grade silicone (tested for skin contact)

- Antimicrobial coating (99.9% bacteria reduction)

- ISCC Plus/GRS certification support

Post-production testing showed a 99.2% compliance rate versus industry-standard 89-93%.

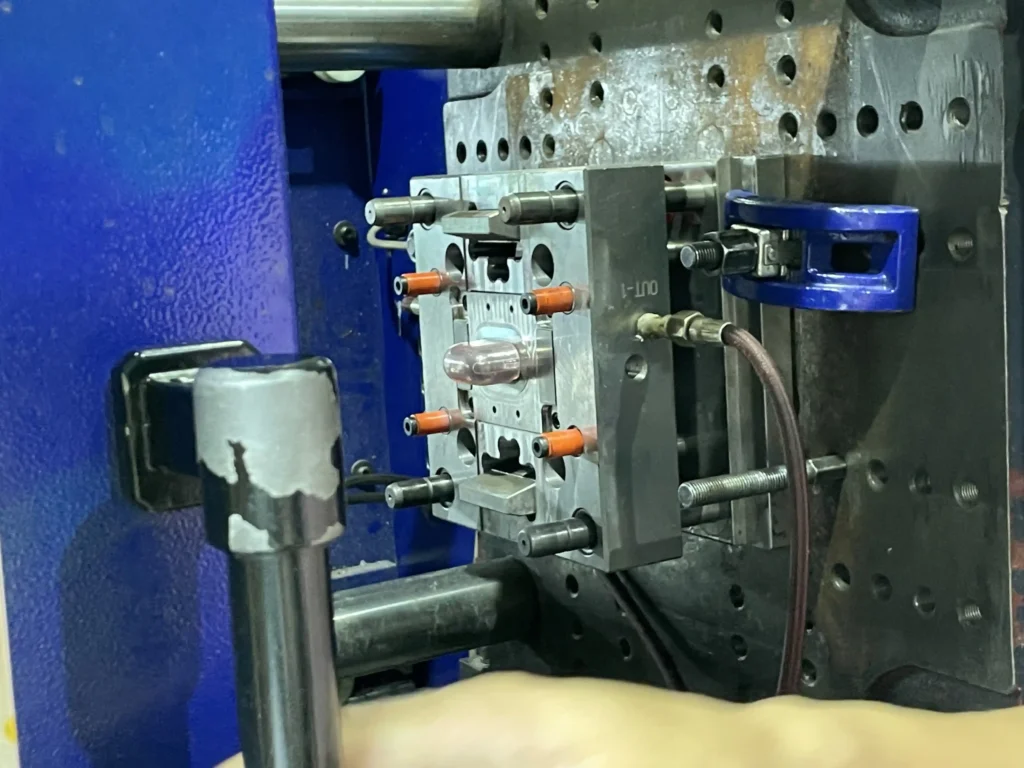

Technical Breakthrough: IM-3D-E Technology

YG’s patented IM-3D-E encapsulation solves wireless charging integration pains:

Cost Comparison

| Factor | Competitor A | YG | Savings |

|---|---|---|---|

| Per-unit Cost | $3.80 | $2.60 | 31.6% |

| Mold Investment | $15,000 | $8,500 | 43.3% |

| Compliance Pass Rate | 87% | 99.2% | 14%↑ |

Sustainable Manufacturing Edge

Eco-conscious brands choose YG for:

This aligns with the EU’s 2027 Circular Economy Action Plan requirements.

Client Success Story

UK-based UrbanEar increased sales by 170% after switching to YG:

- 22-day production cycles (vs. 56 days previously)

- Custom engraving for 5,000-unit batches

- Apple Find My integration support

“YG’s flexible MOQ lets us test bold designs without inventory risks,” says UrbanEar’s CEO.

Why Brands Trust This AirPods Case Manufacturer

- 500-piece order flexibility

- 72-hour prototype service

- Built-in wireless charging expertise

FAQ

Q: What’s the MOQ for custom AirPods Pro cases?

A: 500 units – 20x lower than industry averages.

Q: Do you support MagSafe integration?

A: Yes, our IM-3D-E technology enables perfect alignment with MagSafe chargers.

Start Your Project:

Get Your AirPods Case Prototype in 40 Hours →