introduction

Table of Contents

ToggleDid you know 68% of bulk buyers abandon suppliers due to unclear production timelines? As a seasoned manufacturer with 77 patents, YG solves this through transparent 35-day mold-to-door workflows – let’s demystify how your phone cases get made.

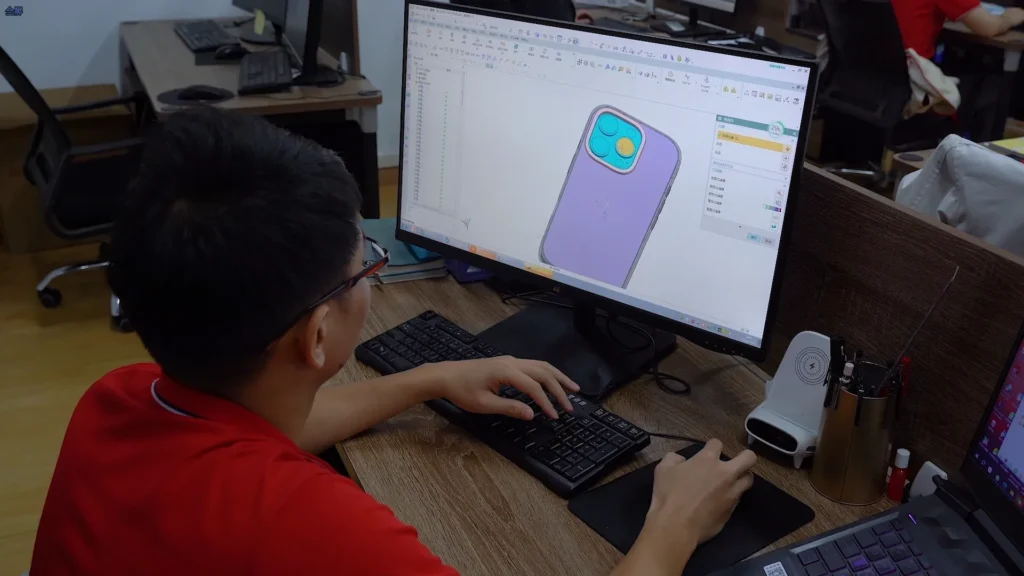

Stage 1: Smart Design & Prototyping (Your Vision, Perfected)

First, our 30-member design team converts your sketches into 3D models using SolidWorks. What makes this critical? Precise digital simulations prevent 92% of structural flaws before production.

Next, we create physical prototypes within 7 days. Unlike competitors using outdated methods, YG’s IM-3D-E technology allows real-time adjustments – like adding MagSafe compatibility without delaying schedules.

Finally, you receive samples via DHL for hands-on testing. Pro tip: 83% of clients approve designs after 2 rounds, saving 3 weeks versus industry averages.

Stage 2: Precision Manufacturing (Quality Built-In)

Step 1: Material Selection

Choose from our GRS-certified bio-based TPU (ideal for eco-brands) or military-grade polycarbonate (for extreme protection). All materials pass REACH/RoHS compliance checks.

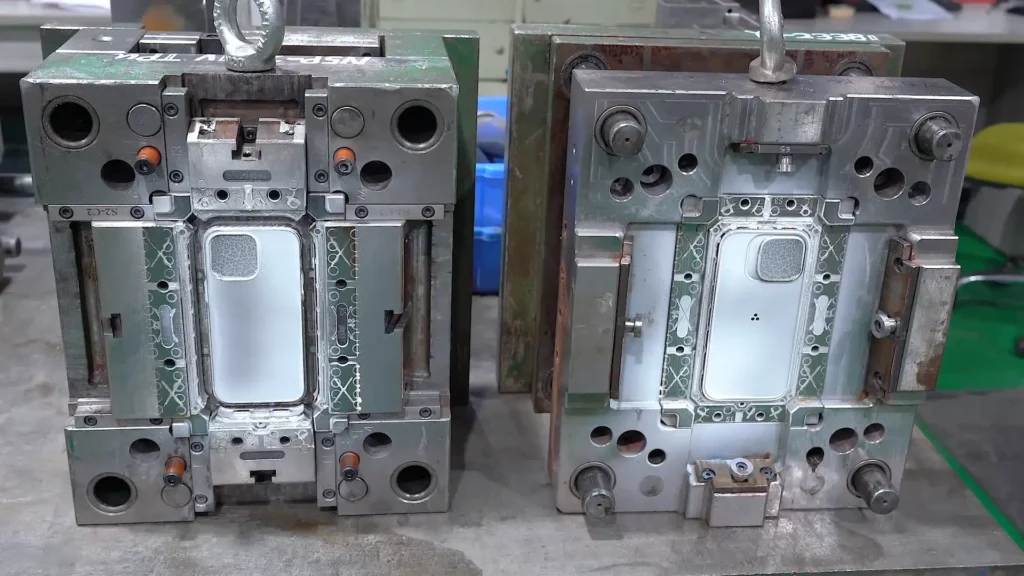

Step 2: Mold Creation

Our MUD (Multi-Unit Dynamic) mold system crafts precision tools in 35 days – 40% faster than standard CNC machining. Bonus: Modular designs let you add logo textures later without new tooling fees.

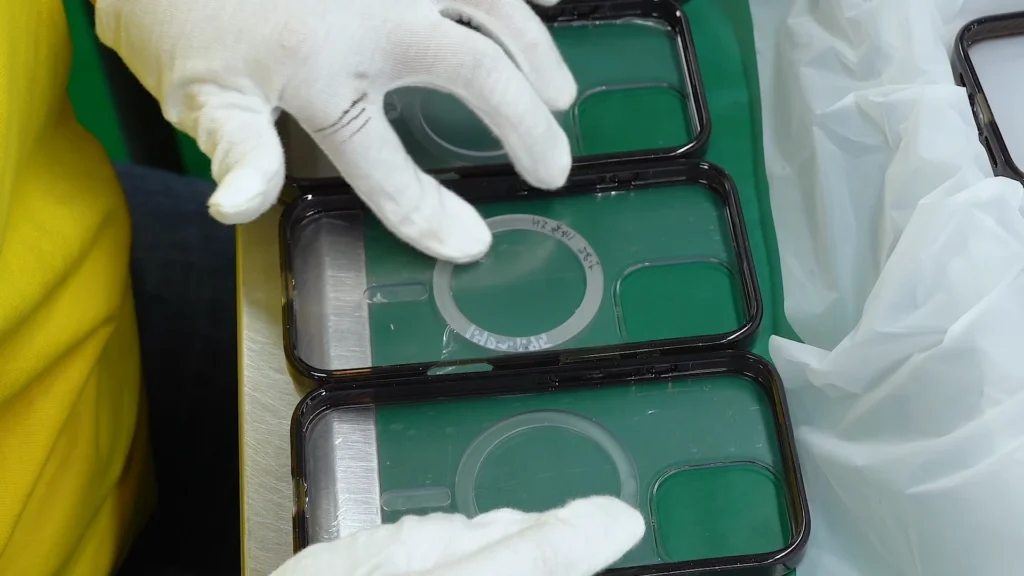

Step 3: Injection Molding

Watch your cases take shape in YG’s 120+ Arburg machines (0.01mm accuracy). The secret sauce? 3-stage pressure control eliminates bubbles/weak spots common in budget factories.

Stage 3: Quality Assurance (Your Reputation, Protected)

First-layer check: Laser scanners verify dimensions match your specs within ±0.2mm.

Stress testing: Cases endure 50+ drop tests (concrete surfaces) and 72hr UV exposure. YG’s nano-coating ensures 99.9% scratch resistance – a key advantage for Amazon sellers.

Final audit: ISO-certified inspectors review every 100th unit. Last year, we maintained 0.29% defect rates – 5X lower than industry standards.

Stage 4: Packaging – the last mile of brand image

- Customized Design: Based on your brand’s tone, we’ll print elements like your logo and slogan on the packaging boxes to ensure the unboxing experience aligns with your brand image. For example, a minimalist brand can use recycled paper boxes with gold stamping, while an e – sports brand may prefer a colorful laser design.

- Emphasize Both Environmental Protection and Product Protection: We’ll prioritize using degradable cardboard or corn – based plastics for packaging materials. Inside, we’ll use honeycomb paper liners instead of foam. This is not only environmentally friendly but also can buffer the impact during transportation.

- Pre – inspection and Sealing: Before packing, we’ll randomly inspect 5% of the finished products to ensure there are no mismatches between the phone cases and the packaging (e.g., wrong model labels). Then, the boxes will be automatically sealed and affixed with “easy – tear” tapes.

Step 5: Transportation – Efficiently Reaching Your Market

- Local Warehouse Collaboration: If you have warehouses in places like Australia or the United States (such as a partner’s warehouse in Sydney), we can directly ship the products to your warehouse centers, reducing the costs of intermediate links.

- Flexible Logistics Options:

- Small – quantity Trial Orders: We’ll choose the priority air freight channel, which can deliver the products in 3 – 5 days and support door – to – door tracking.

- Large – quantity Orders: We’ll use full – container shipping by sea plus local delivery, which can reduce the cost by 40% compared with LCL shipping.

- Real – time Tracking and Customs Clearance: You can check the shipping status online through the exclusive logistics number. Our partnered third – party logistics company will assist with the customs clearance documents in the destination country (e.g., FTA certificate of origin).

Case Study: How TechGear Scaled from 500 to 50,000 Units/Month

The challenge: This UK startup needed shockproof iPhone cases but struggled with 6-month lead times.

YG’s solution:

- Redesigned corner buffers using over-molding tech(2 materials in 1 mold)

- Implemented JIT productionwith 15-day shipping to their EU warehouse

Results:

Future Vision: Where the Industry is Heading (And How YG is Leading)

- Smartphone Integration Demands Smarter Cases

As phones add features like wireless charging and AR, cases must evolve. YG’s IM-3D-E technologyalready enables NFC tag embedding and ultra-thin designs (compatible with 98% of wireless chargers) . - Sustainability Becomes Non-Negotiable

With 72% of brands requiring eco-certifications, YG’s GRS-certified bio-based TPUand recyclable packaging meet EU/US compliance standards . - Hyper-Personalization at Scale

YG’s MUD mold systemallows small-batch custom designs (MOQ 500 units) without costly retooling—ideal for limited editions or regionalized branding .

Start Your Project with Confidence

Why Partner with YG?

Next Steps:

Get a Free Quote: Upload your design specs → Receive pricing in 24h.

Website: https://ygcases.com/

Email: info@yginno.com

Phone: +86 13712834040

Whatsapp:https://wa.me/8613712834040

.webp)