The smartphone accessory market will reach $98.3 billion by 2027 (GVR). Yet 73% of procurement managers struggle to find suppliers balancing low MOQ and industrial-scale capacity. At YG, we operate 120 injection molding machines producing 30,000 phone cases daily while maintaining a 500pcs MOQ threshold. This guide reveals how to audit suppliers using 7 operational metrics that truly matter.

Metric 1: MOQ Flexibility vs. Production Scale

Table of Contents

ToggleThe 500pcs Advantage

While most manufacturers enforce 3,000-5,000pcs MOQs, our 500pcs minimum allows:

- Test 5-7 designs simultaneously with ≤$8,500 risk

- 37% faster time-to-market vs industry average

YG’s Capacity:

- Daily output: 30,000 finished cases

- Peak capacity: 850,000 units/month

- Case Study: A U.S. startup ordered 500pcs each of 8 iPhone 16 concept cases, then scaled the top 3 designs to 50,000pcs/month within 6 weeks via our ODM solutions.

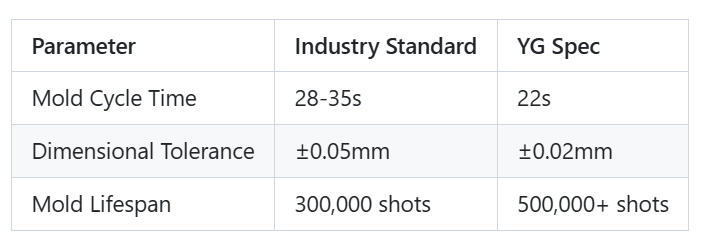

Metric 2: Mold Engineering Mastery

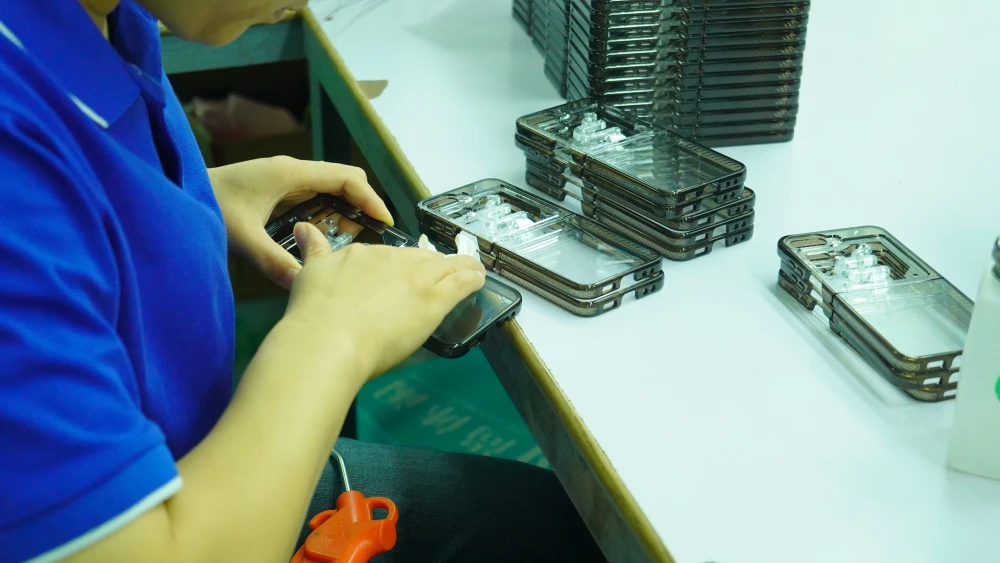

150 Molds/Month Precision

With 120 DKK 550-ton injection machines and 31 engineers, we deliver:

Pro Tip: Ask suppliers for:

- Mold flow analysis reports

- Cooling time optimization data

Metric 3: Certifications Beyond Basics

Compliance as Strategy

We hold 23 certifications including:

- ISO 14001 (Environmental Management)

- ISO 45001 (Occupational Safety)

- Disney FAMA (Licensed Production)

2025-Ready:

- Full documentation for EU’s Digital Product Passport (DPP)

- Conflict Minerals Reporting Template (CMRT) compliance

Metric 4: Customization at Scale

From 500pcs to 500k Units

Our custom phone cases process:

- Design: 24hr 3D rendering (OBJ/STL files)

- Prototyping: 7-day TAT for 500pcs trial orders

- Production:

- 120 machines allocate 15% capacity to small batches

- 48hr material drying → 22s cycle time → 100% AOI inspection

Tech Edge:

- In-mold labeling (IML) for <0.15mm logo precision

- Dual-color molding with 0.08mm interlayer accuracy

Metric 5: Quality Pyramid System

30k/Day Doesn’t Mean Compromise

Our 4-layer QC:

Material

- Shore hardness tests (60D/80A/95A)

- XRF screening for 18 restricted substances

Process

- 120 machines with IoT sensors (±0.5℃ temp control)

- Real-time cavity pressure monitoring

Output

- 100% functional test (buttons/ports alignment)

- AQL 1.0 sampling (Tighter than MIL-STD-105E)

Traceability

- QR code tracking from mold to shipment

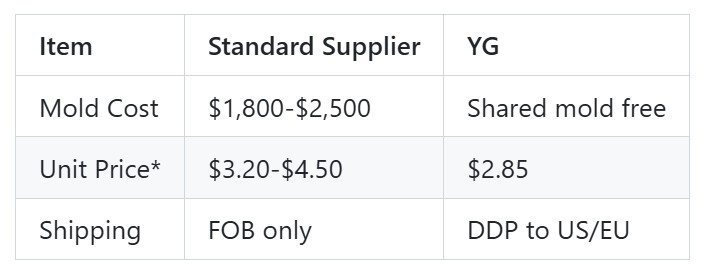

Metric 6: Transparent Cost Structure

500pcs Pricing Breakdown

*Based on 500pcs TPU case order

Hidden Cost Savers:

- No charges for ≤3 design revisions

- Free storage for 60 days post-production

Metric 7: Sustainable Scalability

Growth-Ready Partnership

- Phase 1: 500-5,000pcs with 15-day lead time

- Phase 2: 5k-50k/mo with JIT scheduling

- Phase 3: 50k+/mo via dedicated production lines

Client Example:

An Italian brand grew from 500pcs samples to 120,000pcs/month orders with:

- 22% cost reduction through volume incentives

- Dedicated QC team for EU market compliance

Your 2025 Supplier Checklist

- □ MOQ ≤1,000pcs for testing

- □ ≥100 injection machines

- □ Mold lead time <30 days

- □ AQL ≤1.5 certification

- □ Unit cost ≤$3 at 500pcs

Why Global Brands Choose YG

- Speed: 65 molds completed last month

- Precision: 0.02mm tolerance across 120 machines

- Responsiveness: 15min average quote turnaround

Start with 500pcs Risk-Free Samples →

Technical Appendix

Machine Specs:

- Haitian Mars II 550T presses

- 99.2% uptime via predictive maintenance

- Energy consumption: 0.45kW·h/kg (vs. 0.68 industry avg)

Material Options:

- 45+ verified TPU/PC/PMMA formulations

- 18 anti-yellowing grades