Frustrated by unstable quality, high costs, or delays in bulk phone case orders? As a professional phone case manufacturer, we believe that injection molding can solve these pain points, which is why top manufacturers have such firm faith in it. Let’s analyze its main advantages to help you make wiser purchases.

What is Injection Molding for Phone Cases?

Table of Contents

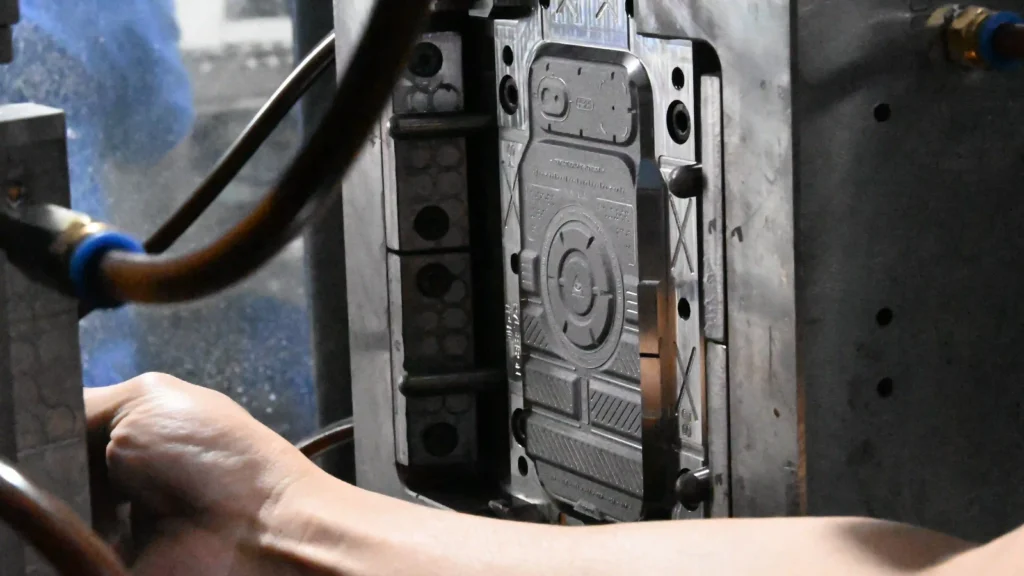

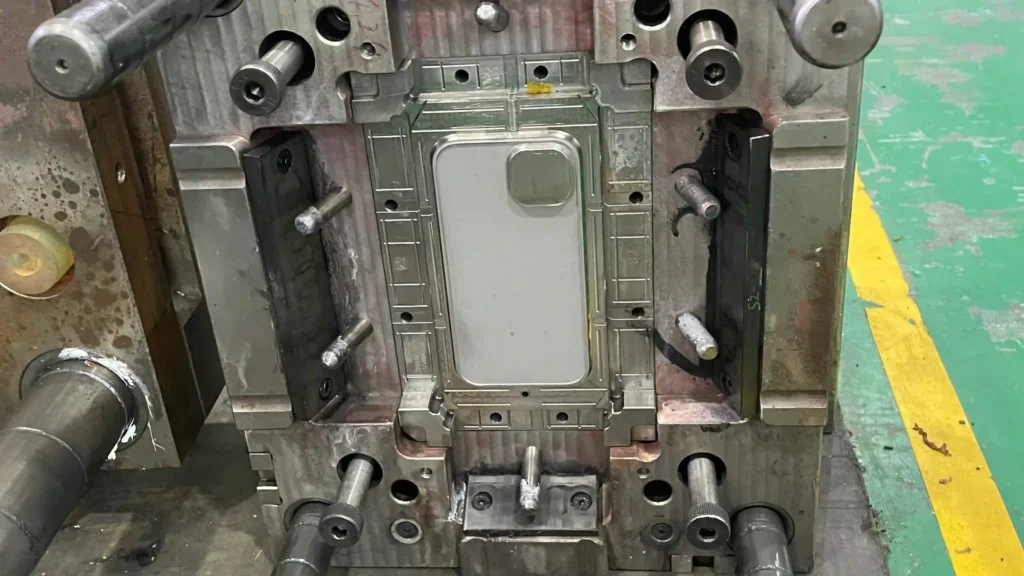

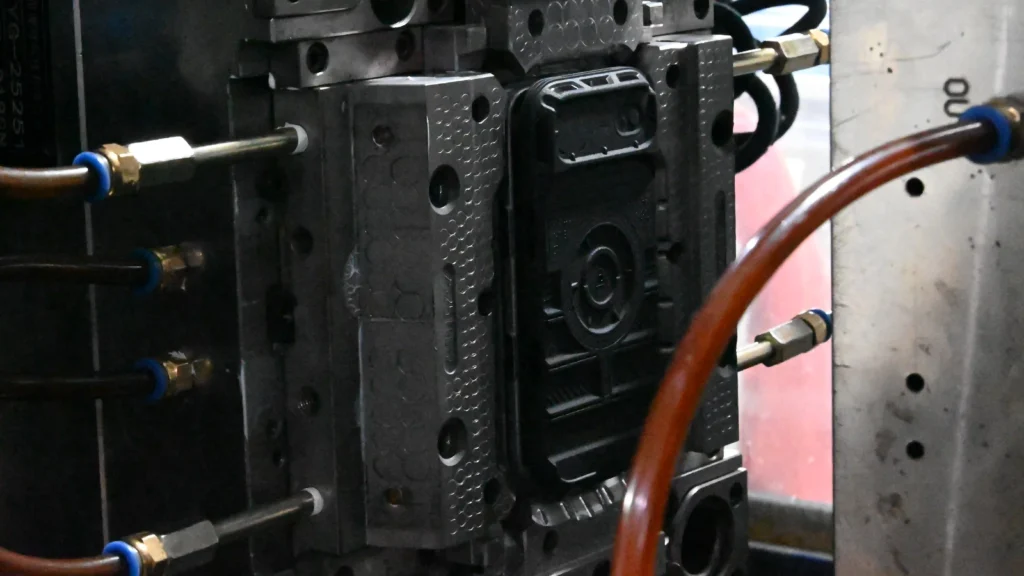

ToggleIf you have ever wondered how phone case manufacturers efficiently produce thousands of identical high-quality phone cases, then plastic injection molding technology is the answer. The core of this process involves melting durable materials, such as TPU, PC, or silicone, and then injecting the molten mixture into a precisely designed mold. After cooling, when the mold is opened, a fully formed phone case is revealed and can be prepared for the final processing.

Unlike manual production (which is slow and error-prone) or 3D printing (which is very suitable for prototyping but not practical for bulk orders), injection molding is designed for large-scale production. This is why professional phone case manufacturing can meet a large number of demands without sacrificing quality – and this is also the reason why buyers who require consistency and efficiency prefer this method.

7 Advantages of Injection Molding for Phone Cases

1. High Mass Production Efficiency

Injection molding is booming in scale. An injection mold tooling can produce thousands (or even millions) of phone cases with the shortest downtime between cycles. For phone case manufacturers, this means that we can complete large orders faster than traditional methods – whether it’s 10,000 pieces or 100,000 pieces.

What good does this do to you? There is no need to be busy meeting the seasonal peak or last-minute customer demands anymore. You will receive consistent and punctual delivery, maintaining your inventory and ensuring the smooth operation of your business. Have you ever faced sales losses because your supplier failed to deliver bulk orders on time? Injection molding eliminates this risk.

2. Save Costs and Increase Profit Margins

Let’s talk about the figures: Although manufacturing custom injection molds requires an initial investment, the unit cost drops sharply as production increases. Unlike the process of making each unit separately, the repeatability of injection molding means that phone case manufacturers can save you a lot of money.

For bulk buyers, this means higher profit margins or more competitive prices. Imagine purchasing high-quality phone cases at a lower unit cost without cutting corners on durability or design. Isn’t this the value you’re looking for from a phone case manufacturer?

3. Design Flexibility to Bring Your Ideas to Life

Do you want a phone case with a unique shape, precise cuts for buttons and cameras, or even a multi-color design? Injection molding technology makes all this possible. Phone case manufacturers can create injection molds for complex geometries, strict tolerances, and even integrated functions (such as pattern textures or shock-absorbing protrusions), which cannot be achieved by other processes.

Whether you are targeting trend-driven consumers or niche markets, injection molding technology enables you to customize every detail of your phone case. From slim and minimalist designs to sturdy and highly protective phone cases – your vision can all come true. Have you ever been restricted because other manufacturers were unable to implement your custom design? Injection molding technology has changed this situation.

4. Quality consistency

Nothing can damage your brand more than inconsistent products – one phone case fits perfectly, another is too loose, and there’s still one with uneven edges. Through injection molding, phone case manufacturers use precision molds to ensure that each phone case is the same. The automated process eliminates human errors, resulting in uniform phone case thickness, perfect fit, and minimal defects.

For you, this means less return, more satisfied customers, and a reliable reputation. When you work with a phone case manufacturer that uses injection molding, you can be confident that each phone case you receive meets your exact quality standards.

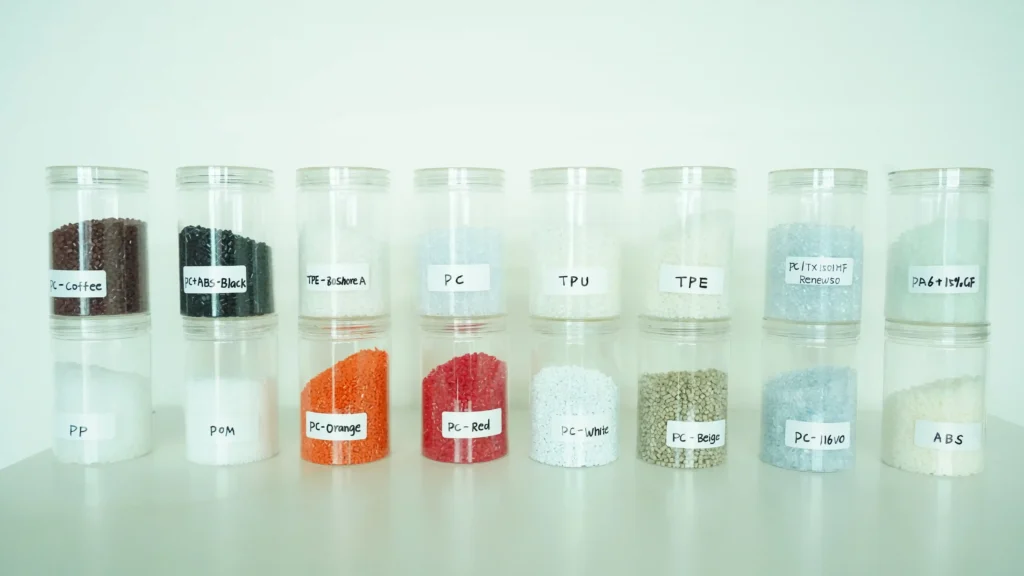

5. Wide Material Compatibility

Phone case buyers have diverse demands: some hope to choose eco-friendly materials, some value extreme durability more, and others require a thin and light design. Injection molding processes support the use of a variety of materials – including recycled plastics, food-grade silicone, impact-resistant PC materials, and flexible TPU materials – so phone case manufacturers can customize products according to your specific needs.

Looking for sustainable phone cases that align with environmentally conscious consumers? We can use recycled materials. Need a sturdy and durable phone case for outdoor enthusiasts? Impact-resistant hybrid materials are the ideal choice. This versatility enables you to expand your product line and cover more markets – all using the same reliable manufacturing process.

6. Standardized production

Injection molding is highly automated, which means that phone case manufacturers can strictly control the production process. From material selection to quality inspection, every step is standardized and traceable. You don’t need to worry about unexpected delays or quality fluctuations – we will always provide you with the latest updates at every step.

As a buyer, this means less time to manage suppliers and more time to develop your business. You can focus on marketing, sales, and customer service, while trusting your phone case manufacturer to provide consistent results.

7. Long-Term Value for Ongoing Success

Mobile phone models are developing rapidly, and you need a manufacturing partner that can keep up. Injection molds are durable and highly adaptable – phone case manufacturers can modify existing molds to fit new phone sizes or update designs without having to start from scratch. This saves both of us time and money, enabling you to respond quickly to market trends.

Whether you are expanding into new product categories or updating your lineup for the latest smartphones, injection molding supports your long-term growth. You will establish a partnership with a phone case manufacturer to invest in your success – now and in the future.

Applications of Injection Molding

Let’s take a look at how injection molding can bring results to buyers like you

- We collaborate with global brands to produce 10,000 TPU-PC shockproof transparent phone cases. Through injection molding, our defect rate remains below 0.5%, and we deliver the entire order within 8 weeks and within budget.

- A buyer hopes to customize a phone case with a unique shape and texture. Our injection molding process can realize his ideas through custom injection molds without increasing production time.

These achievements are not exceptional – they are the standard for phone case manufacturers using injection molding. When you prioritize this process, you are choosing reliability, quality and value.

How to Choose the Right Injection Molding Phone Case Manufacturer

Not all phone case manufacturers are the same. When choosing a partner, please pay attention to the following key traits:

- Proven mold design and engineering capabilities (samples of past works may be requested).

- Have experience in large-scale production and on-time delivery (view customer reviews).

- A strict quality control process (inquiring about defect rates and testing protocols).

- Have the ability to flexibly respond to customized designs and material preferences.

- Commitment to sustainability (if eco-friendly products are your top priority).

As a phone case manufacturer specializing in injection molding, YG has met all these conditions – and is always ready to turn your vision into reality.

Conclution

Injection molding is not merely a production process; it is a strategic advantage for bulk buyers. It offers the efficiency, quality, and flexibility needed to stay ahead in a highly competitive market, which is why top phone case manufacturers rely on it to serve buyers like you.

If you are tired of compromising on cost, quality, or design, and you want a phone case manufacturer that understands your bulk purchasing needs, let’s get in touch. Whether you need a quotation for a custom injection-molded phone case, want to discuss material selection, or have questions about the process, our team can help you.

Contact us today to start our journey of cooperation.